One of the biggest challenges for applications involving distributed generation (DG) through photovoltaic systems is to maximize the total installed power, according to the financial and physical space availability.

The greater the installed power of the photovoltaic array, the greater the energy generation and the number of loads that can be served. However, it is not always possible to approve a new project or expand an existing installation according to the planned power.

The feasibility of connecting new generators to the distribution network depends on technical and contractual issues. Thus, projects may be unfeasible if any of these items are not compatible. For example, it is not uncommon to find installations that have restrictions on the power that can be injected into the grid. Therefore, one of the ways to deal with such situations is through export control through photovoltaic inverters.

Currently the market demands management systems that allow the user a complete view of the energy flow in the installation. Generally, inverters only display information about power generation, but do not indicate parameters of internal consumption of the installation.

This article shows how inverters on-grid are controlled in order to meet the concessionaires’ contract requirements or technical limits. Furthermore, it will be shown how the use of external managers can help manage, limit or even completely block the flow of energy to the electrical grid, even increasing the total power of the photovoltaic array.

Inverter power export control

Photovoltaic inverters have output power naturally limited by the generation of the array connected to their input, and this means that the output power of an inverter can never be greater than the input power.

Furthermore, every photovoltaic inverter has a maximum output power and this value is displayed in the manufacturer's datasheet, and in many cases it is different from its nominal power. For example, an inverter with a nominal power of 100 kW can have maximum output power 110 kW, depending on the manufacturer. This fact is important not only for total energy generation, but for the sizing of cables and installation protection components.

The maximum output power indicates the maximum that the inverter can deliver, being a hardware and software limitation. Even if the equipment is designed to operate with overload on the direct current (DC) side, its maximum alternating current (AC) output power is the upper limit of operation.

How can we proceed if we need to limit the equipment's output power to a value below its maximum power? In that case There are two ways to achieve this goal. The first way to limit the inverter's output power is through the equipment's internal settings. This method is simple and easy to perform, as the inverters allow adjustments in the output power.

The problem with this method is that it must be done manually and does not allow monitoring load variations and instantaneous generation. This means that a share of energy can be lost if the load varies frequently throughout the day.

Another alternative for controlling the generation and export of energy on the grid is through a controller external to the inverter. This alternative allows dynamic generation control based on the customer's instantaneous consumption. This way, it is possible optimize the use of inverters and meet the technical restrictions of injection into the network.

When is export control of inverters on the grid necessary?

Applications with power control are found in residential, commercial, industrial segments and in large plants. These are applications that require a precise balance between load generation and consumption, and the manual control method is not sufficient.

In photovoltaic systems connected to the grid, the energy generated can be used for internal use installation or exported to the energy distribution network. The portion of energy generated and consumed instantly is quantified through the installation's self-consumption.

The higher the percentage of self-consumption, the greater the independence of the installation in relation to the energy concessionaire and the lower the impact of adjustments in energy tariffs for the end customer. The percentage of self-consumption can be improved through inverter generation control, load relocation, with the help of batteries or even with the integration of electric cars into the installation.

The injection control of the inverters is also applications on restricted networks in the power of the connected generator, limitations due to the capacity of protective equipment or transformers.

As an example, we can consider an installation where the transformer's operating limit has been reached. It is not possible to install more inverters and feed them into the grid without overloading the transformer. In this case, an export controller can be used in a way that even with the implementation of new inverters in the installation, the energy produced is only used for use by the loads and does not pass through the transformer.

Medium to large customers who are on Mercado Livre can use inverter control in the mode called “Zero Grid” or “Zero Export”. In this operating strategy, “on-grid” inverters connected to the grid are still used, but the flow of energy to the utility network is eliminated.

Other applications are also possible using inverter export control. These applications will find more and more space in the market as consumers wish to achieve energy autonomy and increase the power of installed photovoltaic generators.

How to control energy export

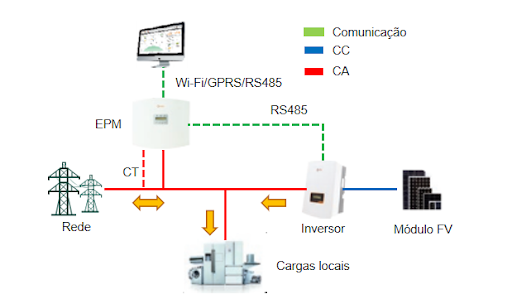

Solis' Exported Power Manager or EPM came to the Brazilian market as a solution for intelligent energy management for residential, commercial, industrial systems or photovoltaic plants. Figure 1 shows a typical application scheme with this component.

EPM is a control system for installations connected to the electrical grid, that is, on-grid systems. This control system makes it possible to measure the energy flow in the installation, as well as the energy injected, or the energy used from the electrical grid, or even measure the consumption of the customer's loads. A typical application of the EPM, as illustrated in Figure 1, is to connect it to inverters through RS485 cabling and to the electrical grid, through current transformers (CTs)

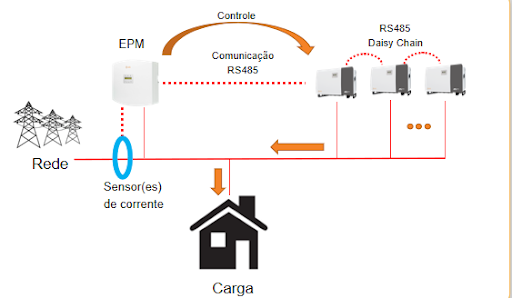

Through EPM it is possible to implement Grid Zero systems and with dynamic power control through real-time monitoring and communication with photovoltaic inverters. This is a solution compatible with Solis single-phase and three-phase inverters, being able to control up to 80 inverters within the same installation.

One of the great differences of EPM is its practicality and ease of installation. Weighing just 5 kg and following a few configuration steps, the equipment can be started and put into operation in less than 10 minutes.

Three versions of EPM were launched on the market, allowing single-phase or three-phase installations to use the solution. The most complete version (EPM3-5G-PLUS) is compatible with three-phase systems at voltages of 220 V, 380 V or 480 V, in addition to having an input for communication via wifi or Ethernet cable.

How does Solis EPM work?

Controlling the generation of multiple inverters in real time based on load variations is not a simple task and requires a lot of processing power, as well as speed and precision. Despite performing a complex function, the operation of the EPM can be described through simple steps.

For the system to function correctly, the EPM must be connected to the customer's input standard, and voltage and current must be measured in each of the phases. Furthermore, communication cables are required RS-485 between the EPM and the photovoltaic inverters. Each inverter receives and sends commands to the EPM through different addresses.

By measuring voltage and current in the input standard, the EPM can determine not only the total power processed, but also its direction. The direction of energy flow can be towards the distribution network or sense of customer load, varying throughout the day depending on generation and instantaneous consumption.

The demand of each inverter is individually determined through an intelligent algorithm in real time, according to the scenarios below:

- Scene 1 - PV Generation < Consumption: In this case, the controller sends a command to the inverters so that their generation is maximized and the maximum power available from the modules is used. The difference between consumption and available generation is covered by the concessionaire's network.

- Scenario 2 – PV Generation = Consumption: Self-consumption is optimized and the inverters receive commands to maintain generation at the current level. The external network is not used.

- Scenario 3 – PV Generation > Consumption: If Grid Zero operation is chosen, then the inverters receive commands so that their generation is reduced to the load level and export to the grid is zero. If Grid Zero is not chosen, then the controller allows a percentage of energy to be injected into the grid, according to the user's configuration.

Case Study with EPM in Brazil

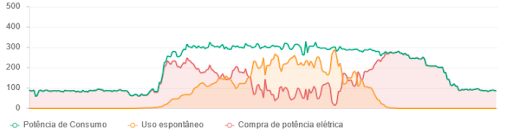

Below you can see the EPM operation chart in an installation with 60 kW three-phase inverters located in the state of Rio de Janeiro. The total capacity of the system is approximately 800 kWp, with a single EPM3-5G-PLUS is used to control 12 Solis inverters. The customer participates in Mercado Livre and wishes not to export energy to the external grid for contractual and grid operation reasons.

Figure 4 shows the energy flow captured by the EPM throughout one day of system operation. This information is made available to the end customer, integrator and distributor through the SolisCloud monitoring platform.

By monitoring the EPM, it is possible to visualize three curves: the total generation of the inverters (yellow), the power used from the network (red) and the customer consumption curve (green). The simultaneous analysis of the three curves shows a complete view not only of generation, but also of consumption in the installation.

The load curve in Figure 4 shows an average consumption of 100 kW during the night. This energy is imported from the concessionaire as there is no local generation. During business hours the average power consumed is increased to 300 kW, where a portion is supplied by the photovoltaic system (in yellow). The difference between consumption and generation is supplied by the concessionaire's network (in red).

It is noted that for a large part of the day, customer consumption is greater than generation, and in this case the energy moves from the concessionaire to the customer, in order to meet demand. Although, There are times when the generation approaches consumption and the control system acts so as not to export energy to the external network.

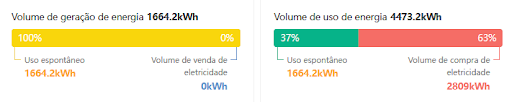

Figure 5 shows a summary of the operation with the EPM. Total values for the selected day are now shown. It is observed that 100% of the energy generated or 1.66 MWh are used for internal consumption of the installation. No value in kWh was exported to the distribution network. This confirms that the system operated as intended by the customer.

In summary, the Solis EPM is equipment that allows export control of inverters, but also the management of energy flow in the installation. The equipment can be used for operation with total injection blockage in the network or GridZero, with simultaneous support of Solis inverters with different powers. Furthermore, complete energy monitoring allows photovoltaic generation to be better harnessed and used locally.