With the rapid development of photovoltaic technology in P type to N type, the difference in power generation of products with different cell technologies is attracting more and more attention.

Currently, cell technologies conventional ones are PERC, TOPCon and HJT.

Each of them has its own advantages and disadvantages, but comparative research on power generation does not yet offer a systematic comparison of the power cycle. complete life based on perspectivethat of global application scenarios.

For this purpose, the central parameters of the three technologies mentioned above.

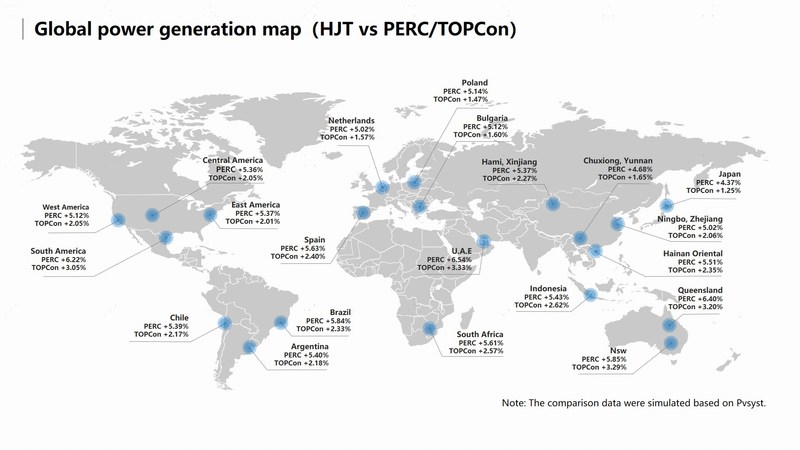

Power generation from utility-scale plants, with these three different panel cell technologies, was studied over a life cycle of 25 years in 21 countries in typical regions, with different climate environments around the world evaluated by Risen Energy to create a comparative map of global energy generation gains.

1. Map of global power generation gains (HJT versus PERC/TOPCon)

Overall, HJT technology products have higher power generation, which is 4.37%-6.54% higher than PERC and 1.25% to 3.33% higher than TOPCon.

Its generation performance energy is more notable, especially in regions with high temperature (e.g. Middle East, Australia and southern US).

With higher 6% gain compared to PERC and 3% bigger compared to TOPCon. As shown in Figure 1.1.

II. Technical analysis of modules

Based on the characteristics of the modules, the power generation gap between different cell technologies in each map region is caused mainly due to three factors: temperature coefficient, bifacial factor and energy degradation.

That's why the modules HJT can offer higher power generation gains and yield more stable energy supply for the photovoltaic system, with its extremely stable temperature coefficient, higher bifacial factor and higher energy retention.

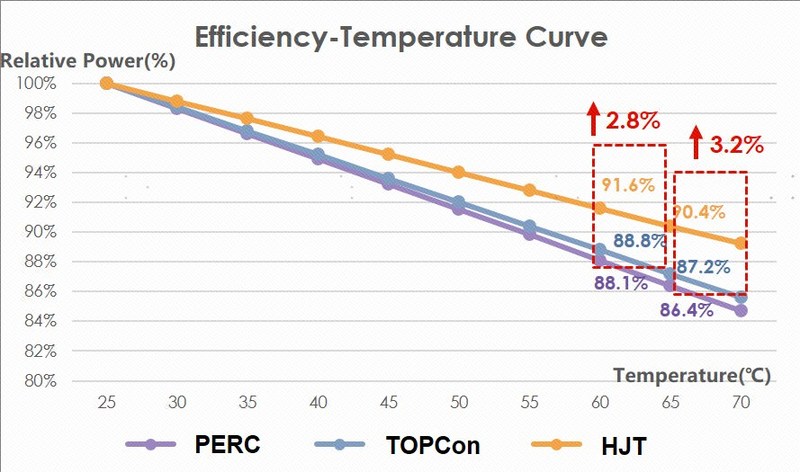

2.1 Extremely stable temperature coefficient

Compared to the power temperature coefficient of -0.35%/°C for PERC and -0.32%/°C for TOPCon, HJT modules have a more stable power temperature coefficient, -0.24%/°C.

Which means that HJT modules offer degradation lower power compared to PERC and TOPCon modules.

As the module's operating temperature increases, thus reducing power generation loss, this generation gain advantage will be realized. especially in case of high temperature of the operational environment, as shown in Figure 2.1.

- At an operating temperature of 60 °C, the relative power of HJT modules is 2.8% higher than that of TOPCon modules and 3.5% higher than that of PERC modules.

- At an operating temperature of 65 °C, the relative power of HJT modules is 3.2% higher than that of TOPCon modules and 4% higher than that of PERC modules.

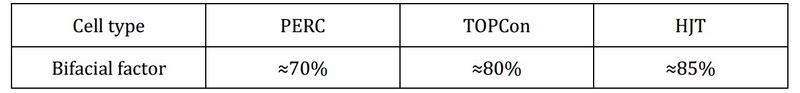

2.2 Higher bifacial factor

With a natural symmetrical structure, the HJT cell is inherently a bifacial cell with currently highest bifacial factor technology, as shown in Figure 2.2.

In the same application scenario, the higher the bifacial factor, the greater the rear power generation gain. The bifacial factor of the HJT modules is approximately 85%, which is about 15% larger than that of PERC modules and approximately 5% greater than that of TOPCon modules, as shown in Table 2.1.

In the same application scenario of utility-scale ground-mounted power plants, the largest bifacial factor of the modules HJT provides high power generation gain compared to PERC and TOPCon modules.

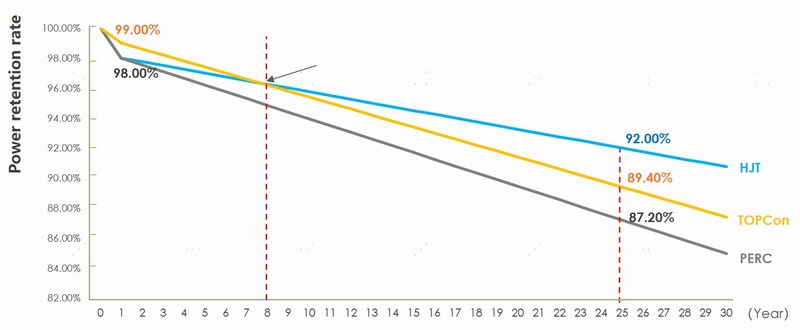

2.3 Greater energy retention

Based on the energy degradation curves of the three different cell technologies, it is clear that by the end of last year, the energy retention rate of HJT modules is 92%.

While that of PERC modules is 87.2% and that of TOPCon modules is 89.4%. This means that HJT products offer better retention of energy production throughout the life cycle of utility-scale power plants.

Which can result in more stable and relatively higher power generation, as shown in Figure 2.3.

As the results discussed above were evaluated with the current degradation of 2% in the first year, the power generation gain advantage will be more notable since the improvement of cell and module encapsulation technology and materials can lead to less degradation of HJT products in the first year.

Above we present a brief performance analysis of HJT cells and modules. However, what are the main factors that affect the power generation of modules? To what extent is the impact significant? Risen Energy attempted to perform additional analysis with PVSYST.

III. Analysis with PVSYST

In terms of factors influence for power generation, typical high and low temperature application scenarios will be selected for analysis respectively.

3.1 Low temperature application scenarios

Harbin city is chosen as a typical example of low temperature application scenario, which is located near 45.9°N with a average annual temperature of 4.7 °C and a total horizontal irradiation of 1,347 KWh/m2.

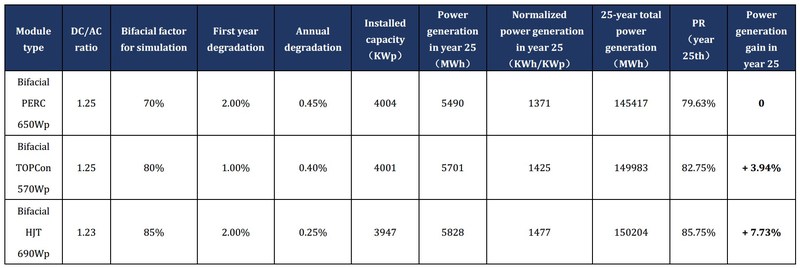

The power plant was designed with a CD/AC ratio of 1.25 and installed capacity of 4 MW (with slight variations in the actual project), using fixed support with ideal inclination angle and suitable string inverters.

By year 25, the gain in energy generation from TOPCon modules is 3.94%, and the power generation gain of HJT is even greater, 7.73%, compared to PERC power generation, as shown in Table 3.1.

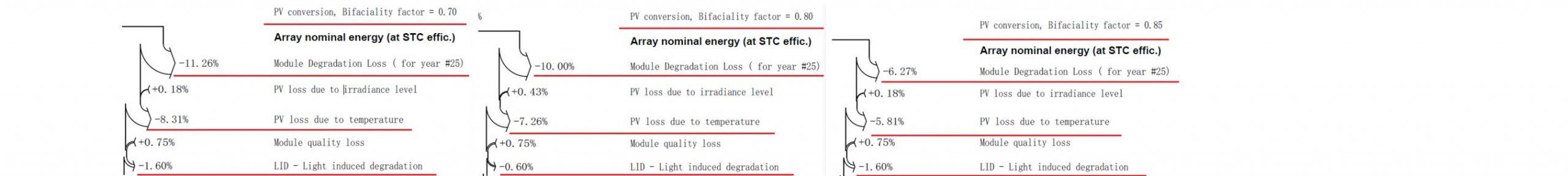

According to the loss comparison, the most important that affects energy generation in low temperature applications it is energy degradation.

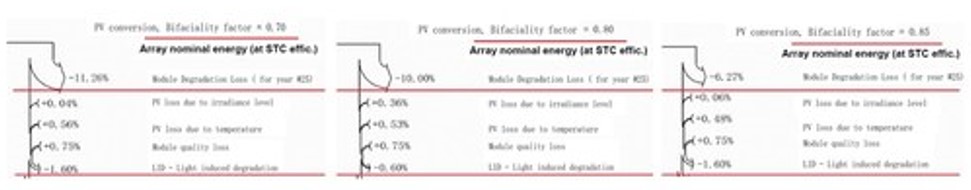

At the end of year 25, the power degradation is 12.86% (1.6% + 11.26%) for the PERC modules, 10.6% (0.6% + 10%) for the TOPCon modules, and 7.87% (1.6% + 6.271 TP3T) for HJT modules. See Figure 3.1.

3.2 High temperature application scenarios

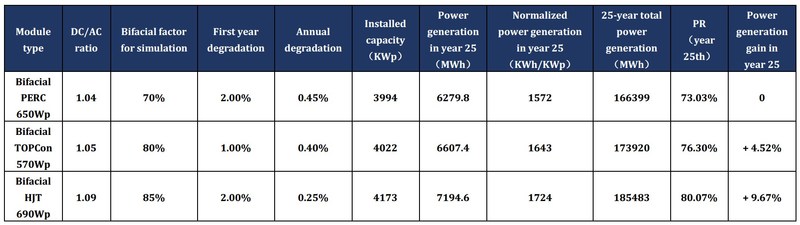

Abu Dhabi in the Middle East is chosen as a typical example of a high temperature application scenario, which is located near 24.4°N with an average annual temperature of 28.5 °C and a total horizontal irradiation of 2,015.1 KWh/m2.

The power plant was designed with a CD/AC ratio of 1.05 and installed capacity of 4 MW (with slight variations in the actual design), applying the ideal tilt angle for fixed supports and suitable string inverters.

By year 25, the power generation gain of TOPCon modules is 4.52%, and the power generation gain of HJT is even higher, 9.67%, compared to the power generation of PERC, as shown in Table 3.2 .

According to the loss comparison chart, in addition to power degradation, operating temperature loss is another important factor that affects power generation in high temperature scenarios.

At the end of last year, the degradation of energy of PERC modules is 12.86% (1.6% + 11.26%), while that of TOPCon modules is 10.6% (0.6% + 10%) and that of HJT modules is 7.87% (1.6% + 6.27%); the operating temperature loss of PERC modules is 8.31%, while that of TOPCon modules is 7.26% and that of HJT modules is 5.81%, as shown in Figure 3.2.

The above analysis shows that in low-temperature application scenarios, module power degradation is one of the main factors affecting product power generation.

And in high-temperature application scenarios, operating temperature is another important factor.

Due to the extremely stable temperature coefficient, higher bifacial factor and higher energy retention of HJT modules, the advantage in power generation gain of HJT is obvious in high temperature areas and low temperature areas.

HJT also shows relatively high power generation gain, which provides higher power generation gain and more stable power yield for the photovoltaic system.