The high demand for photovoltaic systems inevitably reached special customers. Whether due to shading on the roof, the intention of future expansions in the photovoltaic system or for locations with different slopes and/or roof orientations.

Traditional approaches, made with string inverters, can evolve into a more complete product line, to achieve the desired results.

And it is precisely for these situations where the advantage of applying MLPE (module level power electronics) technologies arises. On the one hand we have the solution of power optimizers. Direct current input and output as well.

Compatible with string inverters, the optimizers are intended for situations where there is shading on the roof, preventing the entire modules from being installed in an ideal location for generation. Without its use, the string may lose power and, therefore, generation – often due to few or even just one of the modules.

On the other hand, relying on a different approach, but still being part of the MLPE technology, Microinverters They encompass the characteristics of power optimizers, with the main difference being the output in alternating current.

The device is installed in the profile where the modules are fixed, meaning it is not necessary to install equipment inside the residence. This is one of the great advantages of microinverters, which please customers who are visually uncomfortable with the presence of inverters on the wall, or even who do not have space for them.

Precisely because it is modular, each panel will have its own MPPT, making projects viable where there are different roof orientations and inclinations. Projects with microinverters also have advantages for future expansions.

For example, the Hoymiles HMS-1800-4T microinverter, sold by PHB Solar, has 4 inputs, each with an MPPT. As the integrator does not know which modules will be available for purchase when the customer decides to expand the system, the option is viewed favorably as compatibility with the modules already installed will not be necessary, simply observing the current and voltage .

It is also possible to add up to three microinverters per trunk cable. This way, if only one or two microinverters have been installed at first, part of the existing installation can be reused, without profound changes, when expanding the photovoltaic system, paying attention only to the AC conductor that interconnects the microinverters. to the customer's electrical network.

Analysis of the system's viability must always precede the adoption of MLPE technology. That is, as a distributor we always seek to deliver the best product to the customer, as do our customers, but we must be aware of places that are too shady, with native forest where removal is impossible or where there are buildings that can compromise solar incidence, so as not to make the mistake of making promises that are impossible to achieve.

Projects where generation is not compromised due to shading or different inclinations and orientations may have a more favorable investment value for string inverter technology than with MLPE.

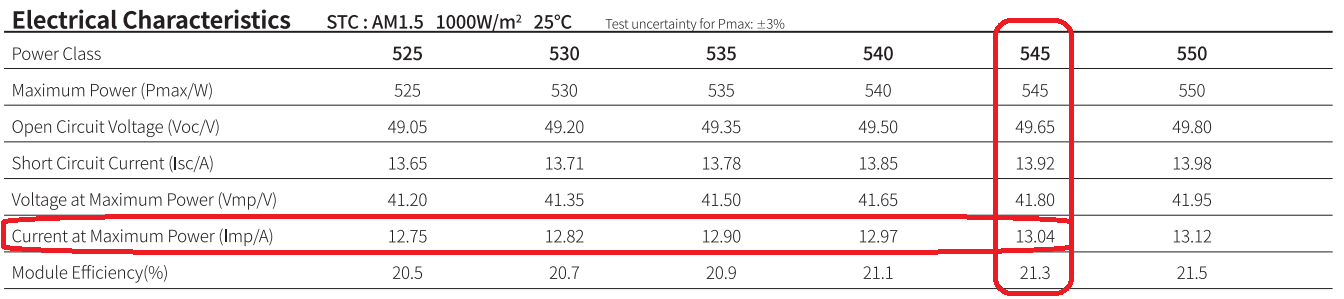

As we mentioned in a previous article (Compatibility of inverters and photovoltaic modules), special attention must be paid to the module current. If it is greater than that of the inverter, clipping may occur and much of the energy to be produced may be lost by shifting the MPPT operating point to make it compatible with that supported by the equipment or to maintain the nominal power.

As we can see in figure 4, the microinverter has a maximum operating current of 13.3 A, compatible with all 182 mm cell modules present on the PHB platform, such as the Longi LR5-72HPH-545M.

The situations presented here highlight the need for simulation using suitable software (PVSol, PVsyst, among others) of the energy generated throughout the life of the photovoltaic system. This will help to understand the gains in using MLPE and also to project the levelized cost of energy. We suggest that, for all cases, regardless of the topology, a comparison be established between the cost and the energy generated.

The questions that need to be answered well are: what size system do I need to use to serve this customer, using MLPE and using string inverters? What is the cost of each one? Does my client have the area for installation? Do the conditions of the current electrical installation support either of the two?

By answering all these questions, we can develop a project that best meets the client's needs and, when presenting the proposal, we can be sure that we are presenting the solution to all the client's problems.

3 Responses

Good morning Pompilio, I apologize for the delay.

Everything will be in the same plant, the inverter and microinverter monitoring (which we work with at PHB) do not make this type of differentiation.

Each company has its own monitoring platform.

Therefore, it has to be monitored separately.

Good morning Ivan! When you place more microinverters with panels of different powers and brands, can you read the data in the same monitoring, that is, in the same plant, or do you have to read the data as if there were two plants?

Grateful!