In collaboration with electrical engineer Wagner Costa

The last paragraph of the document IEEE 2778-D4:2020 – Guide for Solar Power Plant Grounding for Personnel Protection, regarding the commissioning of a large photovoltaic plant (above 5 MWp), can be summarized as follows, in a very loose translation: “Make a good design of the grounding system, based on a good soil resistivity database, because it won’t be possible to measure it later.”

This is an important observation that we must keep in mind when developing the grounding system project for a photovoltaic plant.

Many projects are designed as if a large photovoltaic plant were an SE (substation), based on shallow geoelectric surveys and using software that considers the grounding grid conductors to be ideal.

It is not possible to compare the dimensions of a substation with that of a large photovoltaic plant. The software that is used for an SE, with dimensions on the order of tens of meters, is not necessarily suitable for any type of project, much less for large generating plants, with dimensions on the order of kilometers, as is the case of parks wind and photovoltaic plants.

The IEEE-2778-D4:2020 standard suggests that soil resistivity measurements be made using a matrix of the order of 500 mx 500 m. The standard also suggests that these soundings must be spaced up to 75 m apart, which means an AB opening of the order of 220 m (considering that it is a Wenner measuring arrangement).

Finally, the standard suggests that some large-aperture surveys be carried out, of 300 meters, which means an AB opening of the order of one kilometer, with a view to characterizing the deep layers of the soil, with equipment of compatible power for such testing and field conditions.

A matrix of geoelectrical surveys of the order of 500 mx 500 m has a size of the order of magnitude of a photovoltaic plant sector (group of photovoltaic arrays connected to the same electrocenter).

A geoelectric survey with an opening of 1 km requires the availability of a powerful resistivity meter, which makes it possible to inject a measuring current that provides a good signal/noise ratio and the separation of the Static Potential (SP) from the measurement.

IEEE-2778-D4:2020 notes that due to the large dimensions of large photovoltaic plants, the impedance of the conductors from one end of the mesh to the other can be the order of magnitude of their own grounding resistance, highlighting the importance of a more accurate modeling of the grounding system.

Regarding programs for simulating grounding systems, this standard notes that several programs have limitations, with regard to soil modeling, the maximum number of conductor segments or for not considering the conductors' own and mutual impedances.

This standard, which is the most complete with regard to the grounding system of large photovoltaic plants, makes clear the need for deep soil models and appropriate software, not only for photovoltaic plant projects, but also for parks wind.

According to the IEC/TS 62738:2018 standard – Ground-mounted photovoltaic power plants – Design guidelines and recommendations, a photovoltaic plant is an energy generation plant, access to which is restricted to qualified people and with PPE (personal protective equipment). ) adequate.

According to standard IEEE-2778-D4:2020 (item 5.3.5), the internal area of a photovoltaic plant can be considered a controlled environment, where the use of shoes with insulating soles suitable for a power generation plant may be required. energy.

Based on these premises, the evaluation of the performance of the grounding system of a photovoltaic plant, from the point of view of human safety, must be carried out considering two criteria, one valid for workers inside the photovoltaic plant and the other for anyone who touches the fence. on the external perimeter of the photovoltaic plant.

According to the ABNT 16.603:2017 standard – Electrical Insulating Footwear, the electrical resistance of an electrician's boot must be greater than 1,000 MΩ. The footwear must be capable of withstanding the application of 14,000 V (rms) at 60 Hz for one minute, and the leakage current value must not be greater than 0.5 mA.

Therefore, the issue of human safety inside the photovoltaic plant is not critical, considering that everyone inside is qualified and uses appropriate PPE.

Therefore, the critical region for the purpose of the grounding mesh project is the external perimeter of the fence, where any citizen, barefoot, can touch it. Ideally, the fence should be grounded independently of the photovoltaic plant grid, which is not always possible.

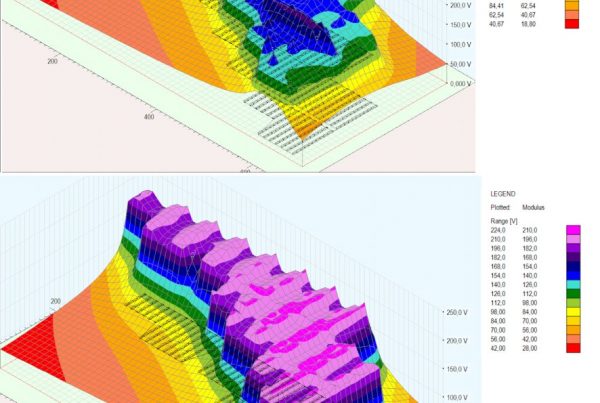

The figure below illustrates the mapping of GPR (Ground Potential Rise) in the simulation of a GD photovoltaic plant (5 MWp) with two types of software:

- above: mesh of real conductors;

- below: mesh of ideal conductors (zero impedance – equipotential mesh).

The difference in the GPR calculated for the two conditions is significant (between 30% and 50%), even for a photovoltaic plant of only 5 MW. For a large photovoltaic plant, the error imposed by a program that considers the equipotential mesh will be much greater, resulting in the mapping of step and touch voltages that are quite different from those that can actually occur.

The worst thing is that the simulation with a program that considers the equipotential mesh presents an optimistic result, not allowing the identification of high potential gradients that occur in the part of the photovoltaic plant close to the substation, and that result in voltages and touch that can exceed the tolerable limits, especially on the external perimeter of the photovoltaic plant fence.

Therefore, the evaluation of the performance of the grounding system of a large generating plant, whether a photovoltaic plant or a wind farm, considering the requirements established in the applicable international standards (IEEE and IEC), requires a whole set of of modeling resources that go far beyond the resources usually applicable to substations and other smaller installations.

3 Responses

Hello, good evening, everyone, I come from the area, from tray assembly to strength electrician and cable laying to substation assembly. We did the grounding according to the projects in each area. Today I am retired, I am in the Renewable energy area and I don't see any problems to carry out On-grid and Off-grid installations always with the same respect for electrical magnitudes. I am still looking for our space by forming teams to enter the properties of residential and industrial clients. I see many fields of work ahead. Improve with this great Master Paulo Freire who will help us a lot in our work.

Excellent article. Highlights key points about UFV grounding. Regarding the appropriate instrumentation, it would be a topic of great interest to be addressed in my opinion.

I'm interested in taking a quick and transparent course for small projects, I want to do domestic installations, like action between friends in the small town where I live..

I have an average level.