Photovoltaic systems are built to operate for at least 25 years. And an important tool to ensure this longevity is commissioning.

Plant commissioning is a standardized and impartial process, whose main objective is to ensure the safe and efficient operation of a given system.

This process must validate the design, execution and equipment used in accordance with standards, laws, good engineering practices and specific requirements of the owner.

Bringing this definition to the universe of photovoltaic solar energy, we can summarize commissioning as the process of verifying and validating the photovoltaic system, aiming to identify problems that could compromise safety and energy generation (kWh) at expected levels.

Several benefits are generated when commissioning is carried out well:

- Maximizes investors' profits, as it reduces exposure to photovoltaic system defects and downtime;

- Reinforces and supports the concern with quality control of the project and installation, engaging the entire team in favor of a well-executed service;

- Prevents fire risks, electric shocks and photovoltaic system malfunctions;

- Avoids rework;

- Encourages installers to be diligent in execution, facilitating project completion;

- Ensures that the project is documented accordingly, facilitating operation and maintenance (O&M);

- Formalizes the transfer of responsibility from the design and execution teams to the system owner or operator.

The commissioning of plants must be carried out by a specialized team, which does not have technical responsibility for the project or execution, with responsibility only for verification, acting as an arbiter of the process as a whole.

Some companies responsible for system engineering and construction incorporate the plant commissioning process into the photovoltaic system assembly and installation process, generally carried out by the execution team itself.

Although this is good practice, looking from the owner's point of view, it is difficult to guarantee the impartiality of these analyses. Often, in public sector works or even in private ventures, contracts include the participation of a third-party company, exclusively for commissioning.

Commissioning must start from the conception of the photovoltaic system, identifying problems proactively in the design and planning phases, preventing them from being carried out in the field, thus reducing the costs of possible repairs and rework. The later a problem is identified in a project, the higher the costs to fix it.

The main rules to be followed in the process are the following:

- ABNT NBR 16274 – Grid-connected photovoltaic systems — Minimum requirements for documentation, commissioning tests, inspection and performance evaluation;

- IEC 62446-1 – Photovoltaic (PV) Systems – Requirements For Testing, Documentation And Maintenance – Part 1: Grid Connected Systems – Documentation, Commissioning Tests And Inspection;

- ABNT NBR 5410 – Low Voltage Electrical Installations;

- NR-10 – Safety in Electrical Installations and Services;

- NBR 16690: Electrical installations of photovoltaic arrays – Project requirements (Draft Standard – in public consultation);

- ABNT NBR 16149 – Photovoltaic (PV) systems – Characteristics of the connection interface with the electrical distribution network;

- ABNT NBR 14039 – Medium voltage electrical installations from 1.0 kV to 36.2 kV;

- ABNT NBR 5419, Protection of structures against atmospheric discharges;

- ABNT NBR 15749 – Measurement of grounding resistance and potentials on the ground surface in grounding systems;

- NBR 5426 – Sampling plans and procedures for inspection by attributes;

- IEC 60364-6 – Low-voltage electrical installations – Part 6: Verification;

- IEC 60364-7-712 – Requirements for special installations or locations – Solar photovoltaic (PV) power supply systems;

- IEC 62548 – Photovoltaic (PV) arrays – Design requirements;

- IEC 61010 (all parts) – Safety requirements for electrical equipment for measurement, control, and laboratory use.

A robust Approval Plan must be developed, considering all possible failure modes. Each failure mode must be classified according to probability and severity. The approval plan must contain an assessment action for each failure mode, with special attention paid to high severity items. Commissioning has three evaluation stages: inspection, testing and performance evaluation.

Inspection

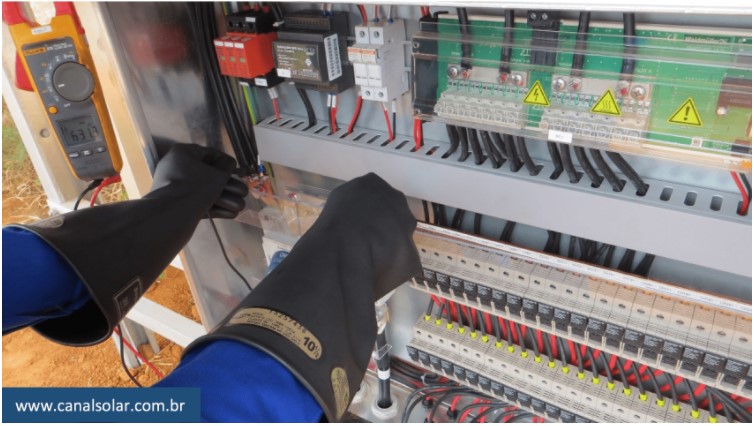

Most non-conformities are identified at this stage. No measuring equipment is used at this stage. Only visual assessments are carried out with the aim of ensuring that no standards or good engineering practices are being violated. The inspection must precede the commissioning tests.

It is important, during the inspection, to confirm that the connections and components are of good quality and that the installed equipment matches, in specifications and number, what is stipulated in the project. A NBR 16274 recommends that the inspection be divided into the following steps:

- CC system inspection;

- AC system inspection;

- Inspection of protection against overvoltage and electric shock;

- Labeling and identification;

- Mechanical installation.

Essay

Commissioning tests aim to identify failures in components of the photovoltaic system or in their assembly. Measuring equipment must comply with the requirements of IEC 61557 and IEC 61010.

Tests must be carried out in accordance with the Approval Plan. NBR 16274 specifies three standard test regimes, namely:

- Category 1 tests;

- Category 2 tests;

- Additional tests.

Category 1 Trials

The standard suggests that category 1 tests be carried out on all photovoltaic systems, regardless of size, type (ground or roof), location or complexity. Essays in this category are listed below:

- Continuity of earthing and equipotential bonding conductors;

- Polarity test;

- Testing the junction box(es);

- Current test of the photovoltaic series(s) (short circuit or operational);

- Open circuit voltage test of the photovoltaic series(s);

- Functional tests;

- Insulation resistance test of the DC circuit(s);

- Testing of the AC circuit(s) according to the requirements of IEC 60364-6.

Category 2 Trials

Category 2 tests, as suggested by NBR 16274, apply to high power or complex photovoltaic systems. It is true that these definitions of size and complexity are subjective, as a photovoltaic system may be complex in one person's interpretation, but not in another's interpretation.

If in doubt, whether they are applicable or not, these tests must be included in the commissioning plan. Before category 2 testing begins, it is recommended that all category 1 testing has been carried out and approved. Category 2 trials are listed below:

- IV curve test of the photovoltaic series(s);

- Inspection with infrared camera (thermographic camera).

Additional assays

If there are failure modes not covered by category 1 and 2 tests, additional tests may be necessary. In some cases, the plant owner requests special testing to address some concern he has. NBR 16274 provides for some additional tests, including:

- Ground voltage tests – systems with resistive grounding;

- Blocking diodes test;

- Wet insulation resistance test;

- Shading assessment.

Performance evaluation

At the end of it all, what matters is whether the photovoltaic system will generate the expected energy. At the end of commissioning, a recurring question for any owner is whether they are getting the amount of energy they anticipated when they made the decision to invest in an SFV.

One of the ways to try to answer this question is by looking at the inverters of the photovoltaic system. The vast majority of inverter manufacturers provide measurement of energy delivered at the connection point, showing these values on online platforms. This way, it is possible to check monthly whether the expected energy levels are being achieved.

However, this simple assessment may not be enough to convince the owner that the system delivers what it proposes, since energy generation also depends on solar irradiation. The question will remain: “Am I generating the amount of energy because the system actually delivers it or because the solar irradiation was greater than expected?”.

In other words, as energy generation does not only depend on a good, well-executed project, but also on climatic conditions, a methodology is necessary that can somehow decouple constructive issues from climate issues. One way to achieve this is to use indicators of performance, being PR (from English performance ratio, or performance index) the most used indicator.

PR is defined in IEC 61724 as the ratio between the actual productivity and the theoretical productivity of the SFV. There is a lot of discussion about whether PR is in fact the best indicator to make this assessment. Despite this, it is by far the most used indicator by investors, designers and builders when discussing performance.

NBR 16274 defines the procedures for reaching PR based on measurements of solar irradiation, temperature, energy, voltage and electric current. The same standard recommends that the assessment be carried out over a period of at least one year.

Documentation

The results of commissioning must be documented in report form and provided to the owner or service contractor. The non-conformities found must be listed, classifying them according to their criticality.

One Response

Hello, I would like to know at what power level it is necessary to commission a photovoltaic solar park, and whether it must be carried out by a third-party company?

I see that this subject is not yet known to many…many companies sell their systems, install them and guarantee everything themselves…I think this is a big risk for the client who is often new to the subject…and even for the contracted company….which You can suffer great damage when turning on the system.

Thank you very much in advance,