Microinverters are devices from the family MLPE (module level power electronics). In direct translation into Portuguese, MLPE means “module-level power electronics”.

Power electronics is the area of electrical engineering that develops electronic power converters (like inverters, microinverters, and other things), while the term “module level” refers to the fact that the microinverters are always installed close to photovoltaic modules.

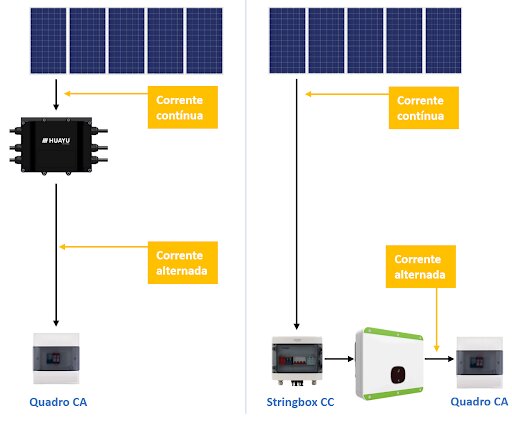

From the point of view of the organization of the photovoltaic system, the main difference between microinverters and conventional inverters is their distance in relation to photovoltaic modules and in relation to connection point to the alternating current network.

Conventional inverters are installed far from the modules and require long direct current cabling, whereas they are closer to the alternating current network.

Microinverters, on the other hand, are installed close to the modules and do not require additional DC cables, in addition to those already supplied with the photovoltaic modules.

In addition to not requiring direct current cabling, microinverters have their alternating current outputs connected directly to the installation's AC protection panel, through the trunk cable, no need for stringbox.

Originally microinverters were intended for use with just one photovoltaic module. With the evolution of technology, microinverters have become larger.

Current microinverters can receive two to four photovoltaic modules, but still maintain their compact characteristic, which allows installation close to the modules (normally underneath the modules, attached to the fixing structures or module frames).

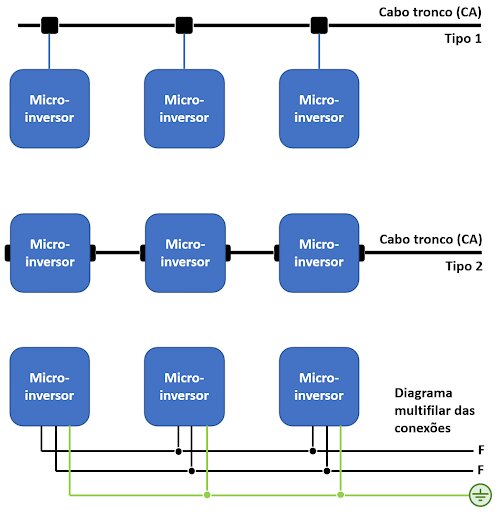

The microinverters are connected to the electrical grid using a trunk cable. The following figure illustrates two possible strategies for this connection. In the first strategy we find what can be called a standard trunk cable (type 1) – which is a continuous cable that has connections through which branches for the microinverters are created.

In the second strategy, also illustrated in the figure below, the microinverters are connected to each other, as in a series connection, and the microinverter at the end receives the cable that will take the circuit to the connection point with the electrical grid.

Regardless of the strategy adopted, the microinverters are always connected in parallel, as shown in the multiwire electrical diagram – also illustrated in the figure below.

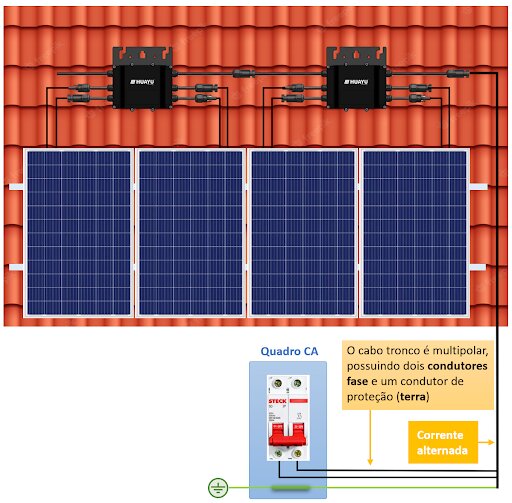

The following figure illustrates a system based on microinverters with inputs for two modules. You modules are connected to the DC inputs of the microinverters. In turn, the microinverters are connected to each other and then connected to the installation's AC connection board. In this case, a system with type 2 trunk cable is illustrated.

5 Responses

“8-panel microinverters already exist. They are already being sold in Brazil by a large, reputable company.”

Interesting. Can you get the name of the company?

There are already 8-panel microinverters. They are already being sold in Brazil by a large, reputable company.

How is Generation monitoring carried out? Will each microinverter emit a WiFi signal and will there be a concentrator to collect the amount?

Hello, Guilherme, how are you? Monitoring is carried out through specific equipment that is connected to the microinverters, and this equipment performs communication between the microinverter and the monitoring software, this communication being carried out via Ethernet (4G or Wi-Fi) or microSD depending on the equipment

Great.