Currently we have noticed a great revolution in photovoltaic modules. The market has requested modules with higher power and solar panel manufacturers have responded to this request.

There are two types of panels being introduced on the market: panels with 182 mm cells, with high voltage (Voc = 50V) and low current (Isc = 13.5A); and also 210 mm modules with low voltage (Voc = 40V) and high current (Isc = 18 A).

As these new panels are rapidly arriving on the market, inverter manufacturers have struggled and are looking for solutions to make modules and inverters compatible.

If we look for the best-selling inverters on the market, we will see that the maximum input current per MPPT is around 26 A and we commonly have 2 strings per MPPT, which gives us a maximum current of 13 A per input, making it impossible to use new panels. high power.

A possible solution to using high power modules with inverters could be to use just one string per MPPT, but we would end up underutilizing the inverters.

A Kehua Tech noticed this market behavior and asked himself: what would be the best strategy to face these challenges? We knew that we would have to follow two premises: the first, that the current supported by the MPPT input must be greater than 26 A; secondly, we would also have to be able to achieve oversizing of at least 30% with our inverters.

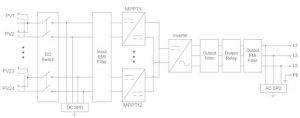

In order to respond to market demand, Kehua Tech recently updated its entire inverter portfolio, with inverters from 30 kW to 60 kW providing a current capacity of 30 A per MPPT.

Furthermore, in inverters from 75 kW to 125 kW we have two customization options: the first has 9 MPPTs (18 strings) and each MPPT can support a current of 30 A or, in the second option, 6 MPPTs (12 strings) are available. and each MPPT can support a current of 40 A – and with these modifications we can achieve DC/AC power outputs greater than 1.5.

Kehua also sought to certify the efficiency of these solutions in conjunction with the TÜV certification body, where we created a test base for these cases and subjected our inverters to various tests, as recommended by TÜV. Thus, we were able to guarantee certification that our inverters are capable of using the most powerful modules on the market.

We can conclude that in the near future, based on our studies, all inverters on the market will have to be updated to operate with these new panels. For inverters from 40 kW to 100 kW, a current capacity greater than or equal to 30 A per MPPT will be required.

Meanwhile, for inverters from 75 kW to 125 kW, for applications with 182 mm panels, a current capacity greater than or equal to 30 A per MPPT will be required. For applications with 210 mm panels, a current capacity greater than or equal to 40 A per MPPT will be required. This way it will be possible to achieve a DC/AC power ratio greater than 1.5 and meet market requirements.

In the near future, in the year 2022, an increase in the module current is still expected, reaching 22.5 A, which again makes it necessary to update the inverters. Anticipating this trend, Kehua Tech developed the new SPI-350K-BH inverter, which has 12 MPPTs with current capacity of up to 40 A each, in addition to supporting voltage up to 1,500 V.