Photovoltaic systems have electrical installations with very particular characteristics, as they operate with direct and alternating currents, as well as having sensitive power electronics equipment, such as frequency inverters.

The installation of a photovoltaic system, in itself, already requires safety precautions and regulatory compliance, such as NR-10 (Safety in electrical installations and services) and ABNT NBR 5410 (Low voltage electrical installations).

When installation takes place in classified environments, care must be taken in the design and execution of the installation.

Atmospheres prone to explosions can be found in the most diverse segments of industry, such as the petrochemical and food sectors, sugar and ethanol plants and the pharmaceutical, textile and cellulose and paper sectors, among many others.

Classified environments and explosive atmospheres

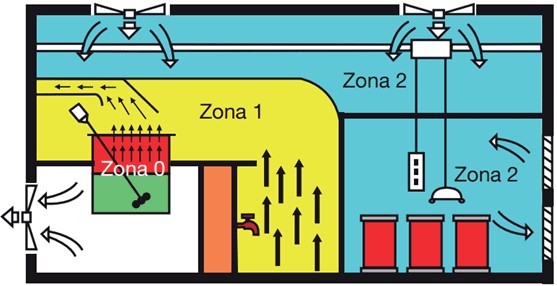

Classified area: is the classification of the plant identified in different zones. These zones indicate the amount of explosive mixture existing at the site and are classified as Zone 0, Zone 1 and Zone 2.

ZONE 0 or 20: place where the occurrence of a flammable or explosive mixture (gases/vapors or dust) exists for long periods, normally being generated by a source of continuous risk. Example: the internal part of a flammable storage tank, atmospheric type.

ZONE 1 or 21: place where the occurrence of a flammable or explosive mixture (gases/vapors or dust) is likely to occur under normal operating conditions of the process equipment, normally being generated by a source of primary risk. Example: I breathe from the same tank, as vapors from the product escape every time its level increases.

ZONE 2 or 22: place where the occurrence of a flammable or explosive mixture (gases/vapors or dust) is unlikely to occur and if it does happen it is for short periods, normally being generated by a source of secondary risk. Example: flanges with aging joints or loosening screws can leak or due to loss of level control.

It is important to highlight that companies are responsible for classifying the area, that is, they can classify them or use specialized companies.

The classification of explosive areas must use not only the floor plan, but also the elevation, as it is not just the risk area, but “risk volumes”. Furthermore, according to the standard, all sources that generate risk, the products that generate the risk and their process conditions must be identified in this document.

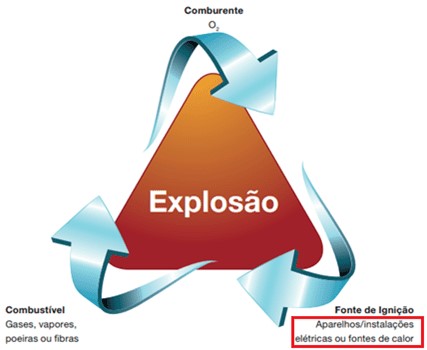

An explosive atmosphere occurs when there is a proportion of gas, vapor, dust or fibers in contact with oxygen, where a spark from an electrical circuit or the heating of equipment can be a source of ignition and cause an explosion. Electrical equipment to be installed in these locations must eliminate or isolate the ignition source, avoiding the simultaneous occurrence of the three components that form the fire triangle: fuel, oxygen and ignition source.

Electrical projects and installations in classified areas

In the industrial sphere, in segments that process flammable substances and are therefore subject to the emergence of explosive atmospheres, the occurrence of a possible spark in the electrical installation can lead to explosions with serious consequences for the community (RANGEL JUNIOR, 2011).

NR-10 mentions some points worth highlighting, such as:

- All equipment used in classified areas must be certified.

- Workers must receive specific training, according to the risk involved.

- In electrical installations in areas classified or subject to a high risk of fire or explosions, protective devices must be adopted, such as alarm and automatic sectioning to prevent overvoltages, overcurrents, insulation failures, heating or other abnormal operating conditions.

- Services in electrical installations in classified areas may only be carried out with permission to work with formal release or suppression of the risk agent that determines the classification of the area.

Another relevant standard that addresses in detail all types of classifications, as well as equipment installation and certification procedures, is ABNT NBR IEC 60079 (explosive atmospheres).

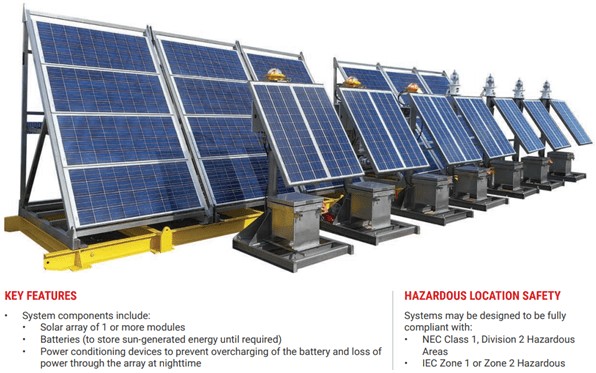

In the photovoltaic area, the Pharos Marine, The JCEenergy, CPR (Rig control products) and the Tideland Signal, manufacture Ex-certified solar modules, inverters and battery banks. Most of these systems were developed for very remote applications, such as offshore oil platforms.

It is important to highlight that equipment with Ex classifications, which have very resistant casings and certifications, cost dozens of times higher compared to conventional equipment for common atmospheres. Therefore, the designer needs to check alternatives such as remote generation or other energy sources that best suit the project, to guarantee the economic viability of the photovoltaic project.

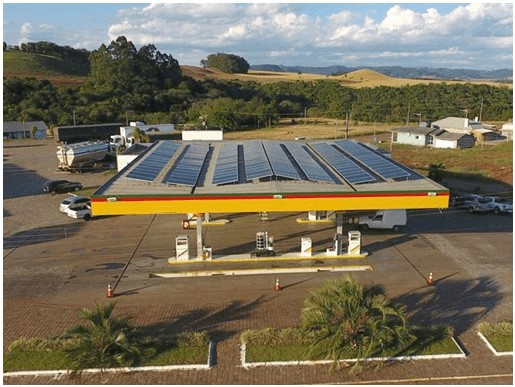

Currently, in Brazil there are some records of photovoltaic systems at gas stations, which paves the way for a new niche of customers. It is important to highlight that throughout the planning, execution and maintenance of the work, a qualified professional, such as a safety technician or safety engineer, must be consulted to carry out all necessary analyses, including the classification of areas.

Performing the installation

Preferably, hot services (using tools such as drilling, poly-cutting, welding, etc.) should be carried out during non-operational times or scheduled plant shutdowns, in order to minimize the chances of generating an explosive atmosphere. The following steps can be followed:

- Prepare an APR (Preliminary Risk Analysis) with the team involved in the operation

- Request the issuance of PT (Work Permit);

- Promote the dissemination of APR and PT with the SMS manager through safety dialogues with employees;

- Check the condition and functionality of equipment and PPE (Personal Protective Equipment) to be used in the service;

- Promote isolation and signage of the area, making sure that only people involved in the activity have access to the location;

- Promote the installation of fire extinguishers (PQS and CO²) in a strategic position, facilitating their use in the event of an emergency;

- Check and monitor the site's explosiveness before releasing the service and throughout the duration of the activity, using an explosimeter;

- When necessary, purge, inertize, double block and label valves and safety devices;

- The activity must be monitored full-time by a security technician and the person responsible for PT. The operation of machines and equipment such as welding, which expose people to risks, can only be carried out by qualified workers.

Most common errors encountered

Incorrect use of conduits

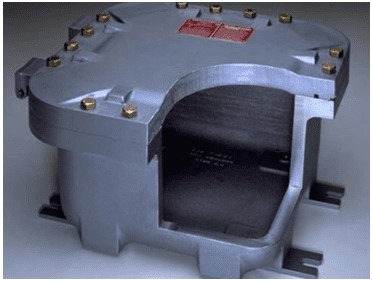

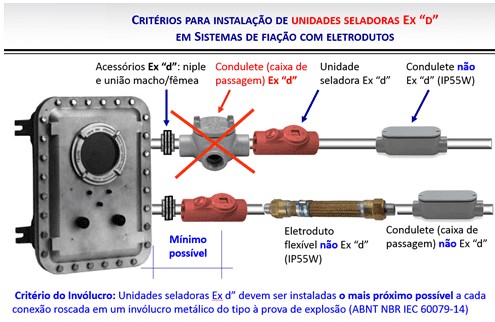

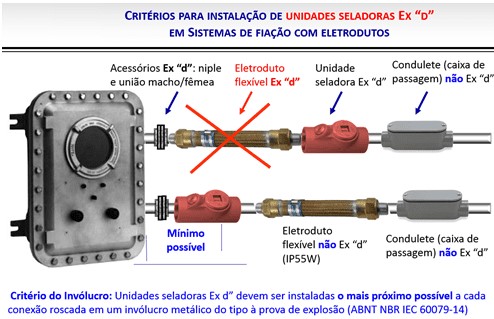

According to Standard ABNT NBR IEC 60079-14, an Ex “d” sealing unit (Figure 10) must be installed as close as possible to the Ex “d” casing, in order to avoid the undue “sum” of equipment volumes Different “d” exes.

Therefore, Ex “d” “conduits” (including conduit accessories or Ex “d” cable passage boxes) and conduits cannot be installed between the Ex “d” casing and the Ex “d” sealing unit.

Conduits can be installed “after” the sealing unit. In this case, the conduit does not need to be Ex “d”, and may have technical characteristics such as IP55W degree of protection and internal dimensions suitable for the bending radius of the electrical cables.

Use of thread sealing tape (Teflon) and silicone

Improper use of thread sealing tape (teflon) and silicone in threaded joints of explosion-proof metal enclosures alters the propagation characteristics of metal-to-metal joints. The use of Teflon and silicone tapes is not mentioned or recommended in the standards applicable to the assembly of “Ex” equipment: ABNT NBR IEC 60079-14, ABNT NBR IEC 61892-7.

The improper use of this type of product is also not indicated in the respective installation manuals or in the manufacturers' “Ex” certificates of conformity. The solution to prevent water from entering inside Ex “d” metal casings with threaded entries must be the use of petroleum jelly or silicone-based grease.

Use of electrical tape

Insulating tape must not be used in hazardous areas, as “splicing” conductors or cables in hazardous areas is not permitted (see ABNT NBR IEC 60079-14/2016 – Section 6.6.2 – Conductor terminations)

The solution for connecting conductors in hazardous areas is the use of a terminal box with “Ex” protection type and EPL suitable for the installation location (Zones and Groups).

For example, terminal boxes with Ex “e” or Ex “t” types of protection must be used, with plastic casings, which do not require sealing units or Ex “d” cable glands, facilitating assembly, inspection, maintenance activities , repairs and “Ex” recovery.

Final considerations

Electrical equipment in classified areas is a source of ignition, either by the spark from opening and closing contacts, by high temperature or by faults in its mechanism.

The basic action is to prevent possible ignition sources from coming into contact with the explosive atmosphere, using special electrical and electronic equipment and explosion-proof infrastructures. As these products are mostly expensive, the installation must be very well dimensioned, to avoid unnecessary excesses and expenses.

It is important to remember that keeping the system in order and complying with the energy company's safety procedures is the responsibility of the owner of the photovoltaic solar energy generation system.

It is also important to check the routing of the panel output cables in order to avoid classified areas (places with the presence or possibility of the presence of a flammable mixture).

In order to comply with the requirements for the use of electrical equipment in hazardous areas, some photovoltaic system technologies such as microinverters and DC/DC optimizers are recommended in these special environments, as they minimize or completely eliminate the risks of sparking and ignition.

Legal notice

The author disclaims any responsibility for the information presented here. The purpose of the article is only to bring light to the main safety points in electrical installations in classified areas. Every electrical installation must be designed and carried out by a duly qualified, qualified, authorized and qualified professional.

The author used figures in this article that may be protected by copyright. If you are the author of any of the figures presented, please notify Canal Solar: [email protected].

Bibliography

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR IEC 60079 – Atmosferas Explosivas, Rio de Janeiro, 2016. ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR IEC 61892-7 Unidades marítimas fixas e móveis – Instalações elétricas Parte 7: Áreas classificadas. Rio de Janeiro, 2017. BULGARELLI, ROBERVAL. Cinco coisas que não podem ser utilizadas em áreas classificadas, 2018. CAMPOS, Iberê M. Dimensionamento cuidadoso e execução correta garantem instalação elétrica de qualidade. Instituto Brasileiro de Desenvolvimento de Arquitetura (IBDA), 2012. CREDER, Hélio. Instalações Elétricas. 15.ed. Rio de Janeiro: LCT, 2007. RANGEL JUNIOR, Estellito. A eletricidade como fator gerador de incêndios. 2011. Disponível em: < http://programacasasegura.org/br/wp-content/uploads/2011/07/A03.pdf> Acesso em: 06/05/2019. <https://static.weg.net/medias/downloadcenter/h72/h91/WEG-atmosferas-explosivas-50039055-brochure-portuguese-web.pdf> Acesso em: 06/05/2019. <http://www.mnconsultoria.com.br/instalacoes-eletricas-areas-classificadas> Acesso em: 06/05/2019. <http://trabalho.gov.br/images/Documentos/SST/NR/NR10.pdf>Acesso em: 06/05/2019. <https://segurancaocupacionales.com.br> Acesso em: 06/05/2019. <https://www.toledobrasil.com.br/blog/artigos/detalhe/aprenda-a-definir-uma-atmosfera-explosiva-e-uma-area-classificada> Acesso em: 06/05/2019. <https://www.automaticpower.com/product-guides/2018-Pharos-Marine-Automatic-Power-Offshore-Product-Guide.pdf> Acesso em: 07/05/2019. <https://www.jceenergy.com/product-range/hazardous-explosion-proof-areas/solar-power-systems> Acesso em: 07/05/2019. <https://rcpat.com/pdf/Solar-Power-Unit.pdf> Acesso em: 07/05/2019. <http://www.tidelandsignal.com/File%20Library/Documents/Spec%20Sheets/EX-Solar-Module.pdf> Acesso em: 07/05/2019. <http://g1.globo.com/sp/santos-regiao/noticia/2015/04/incendio-atinge-industria-no-bairro-alemoa-em-santos-litoral-de-sp.html> Acesso em: 07/05/2019.

About the author

Vinicius Mariano Batista Barbosa. Graduated in Control and Automation Engineering (UNIP – Universidade Paulista). He has an MBA in Engineering Leadership for Emerging Leaders (MIT – Massachusetts Institute of Technology) and Executive MBA in Business Management (FGV – Fundação Getúlio Vargas). He is a technician in Electronics (College Técnico Industrial da UNESP – Universidade Estadual Paulista “Júlio de Mesquita Filho”). Took Extension courses in Photovoltaic Systems at UNICAMP – State University of Campinas. He has ten years of experience in the fuel distribution sector. He is an intrapreneur focused on innovation and optimization of logistics and management processes. It is currently starting projects in the area of photovoltaic solar energy.

One Response

Great text! Subject little explored in the solar segment.