It is commonplace in life of integrator be asked about hybrid systems with battery, often even before starting to negotiate the on-grid system, which in turn is much more popular in the market, both in terms of cost and benefit.

The doubts begin not in the technical part of the system, but in the commercial part: How to deal with this topic? How to offer It is when to offer one hybrid system?

First of all, we need to understand that if in a on-grid photovoltaic system without batteries We couldn't treat the sale like a cake recipe, now we will be sure that an on-grid photovoltaic system with batteries is nothing like a cake recipe.

Naturally, there is a different cost for Implementation of that system, especially for the inverter and batteries. We can now make perhaps the most important observation here: the greater the backup power and autonomy, the greater the cost, since we will have a larger inverter and also a larger storage system.

Figure 1 shows examples of lithium and lead acid batteries.

Figure 1 – PHB lithium battery and lead acid battery, respectively. Which is the best? Image: PHB Solar/Disclosure

The most important point when preparing a budget for a hybrid photovoltaic system with energy storage will depend directly on the backup loads.

These loads will define the sizing of the battery bank and also the inverter and, consequently, the basis of the budget for a hybrid system. Within this context, it is clear that each project will have a unique profile, which will depend on the particularities of each client.

It is routine to size on grid systems based on the historical average consumption extracted from the energy bill. However, when sizing hybrid systems with energy storage, two customers can have exactly the same consumption history and have completely different systems. Since it will depend on the consumption profile of this customer and the number of backup loads that are intended to be had.

Figure 2 presents an example of an energy bill with consumption history.

Figure 2 – Example of consumption history that can be used to size photovoltaic systems. Graphic: PHB Solar/Disclosure

In a commercial meeting, where the aim is to enable the implementation of a hybrid system with energy storage, some technical aspects are important to check, such as:

- What is the voltage of the backup loads?

- What electrical devices will be used to back up the hybrid system?

- What is the backup power?

- How long do you want to have that backup power?

- How frequent are power outage events?

- On average, how long does a power outage last?

- Where is the best place to safely place the inverter and batteries?

Once these questions have been answered, one must also look at the customer's general low voltage (QGBT) framework, whether there will be a need for separation of circuits to serve backup loads. For example: the same circuit that serves several kitchen loads can be separated so that there is an exclusive circuit to power refrigerators and freezers, which are the loads that the customer decided to use as a backup.

Questions 2, 3 and 4, listed above, serve as parameters to define the power and energy of the hybrid system. Questions 5 and 6 serve to understand the client's needs and prepare an optimized project, aiming to mitigate the client's pain and prepare a more assertive budget.

This detail must be well defined so that there is no customer frustration regarding the scaled system and the ability to meet the needs raised. A more careful analysis will allow the creation of an optimized project, which satisfies technical needs and at the same time has greater attractiveness.

One thing to be careful about is that, in the stage of preparing the list of loads that will be placed in backup, the customer usually ends up placing a high number of loads, which normally leads to the sizing of a hybrid system with very large storage.

This will impact the investment to acquire the system, that is, the customer's financial contribution will have to be high and may make the investment unfeasible. It is up to the integrator to guide the client and present an optimized technical solution that meets the needs of the project and is financially viable.

When defining backup loads with the client, it is important to make it clear that the quantity of these loads and the stipulated time of use in backup mode is an important premise of the project, and that, in cases where there is no electrical network and the backup mode operation is backup, a deliberate use of energy can result in shorter supply times on these occasions, as the battery has a limited capacity.

Moving forward on the subject and talking a little about the types of batteries used in these projects, it is worth highlighting lead acid batteries and their depth of discharge. Discharge depths greater than 60% of its total storage capacity have a severe impact on its useful life.

This means that this type of battery technology, if it is the option of choice for use, must be well sized considering a discharge depth so that the battery's useful life lasts as programmed.

Figure 3 presents a curve with the useful life of the lead acid battery in number of cycles in relation to the depth of discharge used.

At this point, we highlight that a customer who suffers from daily absences of considerable duration will suffer a greater impact than a customer with few monthly absences of shorter duration, as this can cause the battery to be more drained.

Therefore, great attention must be paid, because, if the customer can purchase the system with these batteries and start using much more than was planned, whether in power or energy, the entire battery bank could be replaced in a timely manner. prematurely, frustrating project plans.

At PHB, we work with single-phase hybrid inverters and 48V banks, therefore, if lead acid batteries are used, the minimum bank must be 4 12V batteries in series. If a lithium ion battery is used, series association is not necessary, as the battery already has the necessary output voltage at its terminals to be compatible with the inverter input.

In the case of lead acid batteries, the banks can be extended up to a total of 16 units (4 sets of 4 batteries in series parallel). In the case of lithium ion batteries, up to 6 batteries can be associated in parallel.

Figure 4 presents a curve with the number of cycles of a lithium ion battery in relation to its state of health (state of life) when considering a depth of discharge (DoD) of 90%, common for lithium ion batteries.

Still in this image, you can see a great advantage of lithium batteries, their durability, as they have a high discharge depth and yet a greater number of useful life cycles than lead acid batteries.

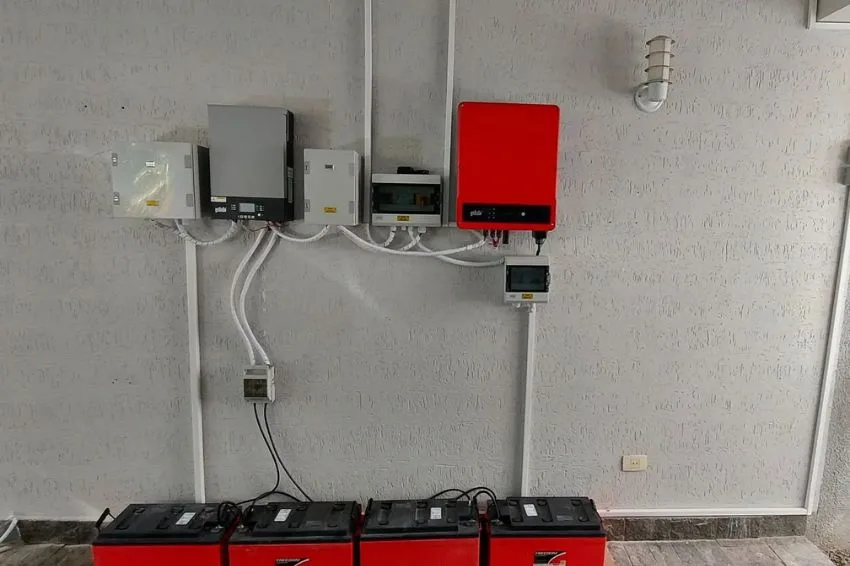

Answering the last question, question 7 listed at the beginning of this text, in hybrid systems with battery storage there is a greater volume of equipment, compared to ongrid systems, precisely due to the presence of batteries. Therefore, a safe location must be provided and/or even propose adjustments to the client to create a suitable environment to install the new system.

The image in Figure 5 shows an example of configuration and storage location for the system with batteries.

Regarding hybrid inverters, PHB offers different models. The PHB3548-ES hybrid inverter, which has 3500W of power and a backup port voltage of 127V, and the PHB3648-ES and PHB6048-ES inverters, with powers of 3600W and 6000W, respectively, both operating at a voltage of 220V.

Thus, answering question number 1 at the beginning of this article about the voltage level of backup loads, if the voltage level of the loads is 127V, the PHB3548-ES model can supply these loads without the use of transformers, as it has output voltage of 127V. If there is equipment at both voltage levels (127V and 220V), it is recommended to use the hybrid inverter from the 220V line with the use of an autotransformer, which is also available with the kit.

To conclude this article, two different examples will be demonstrated. The table below presents two cases, A and B. In case A, there is a list of loads with their powers and the energy that the backup system must be sized to have 6 hours of autonomy must be estimated. In case B, there are the same loads, but with different powers and the autonomy of the backup system will be 10 hours.

For case A, using the 6 hours of backup, there is a total of 4.08kWh of energy. For case B, considering 10 hours of autonomy, it would result in an energy of 24.3kWh.

The battery system must be sized to meet this volume of energy, but it can be seen that there is a large difference between the values. In this analysis, the number of batteries sized will be very different between cases A and B, due to the power of each load and the autonomy required for each case.

This detail shows how relevant the relationship between the load profile and customer behavior directly impacts the sizing of the storage system.

The customer's consumption profile is unique and therefore each project will have its particularities and dimension. Deviations in the time of consumption using loads in backup mode may result in the previously designed system not correctly serving the customer as initially programmed.

Low power loads used during this period will always have less impact on battery discharge, but the customer must be aware of the importance of their consumption profile for the system's durability according to the project.

This represents a substantial difference in the list of materials and the cost for implementing hybrid systems, and the selection of loads ultimately defines the closing of the deal. Firstly, the client is led to unfounded extravagance, and the conduct of the negotiation is guided by technical knowledge of the market, which brings positive results, and speculation without knowledge leads the client to remain on the sidelines, suspicious.

It is also worth highlighting that PHB has an exclusive solar UPS system, which allows the creation of a backup system for customers who already have an on-grid system in operation, reusing the inverter and modules already installed and creating a separate network to supply priority loads. in the event of a power outage from the concessionaire's network. We cover this solution in detail in this article It is in this webinar.

On our sales platform we provide a table to facilitate the definition of the battery bank and we have a team of engineers to analyze the best solutions to meet different cases. It is also worth remembering that for large systems we have the energy container that we discussed in other articles, right here on Canal Solar.

The opinions and information expressed are the sole responsibility of the author and do not necessarily represent the official position of Canal Solar.