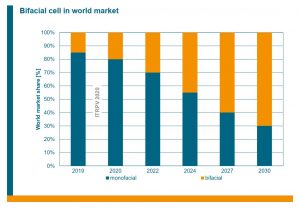

Bifacial modules have already made it clear that they are here to stay. Data from VDMA [1], which carries out studies on the evolution of the global photovoltaic industry, already points to the growth in the manufacture of bifacial cells in relation to conventional cells (Figure 1). Furthermore, experts say factories should only produce bifacial cells in the future. For those who are not entirely familiar with bifacial module technology, it is recommended to read the article Understand bifacial solar modules.

Bifacial modules take advantage of the incidence of sunlight on both sides of the module. From the front of the module, the main source of energy is global irradiation (sum of direct and diffuse), in which solar rays fall directly on the module without suffering any deflection or reflection. From the back of the module, the energy source is reflected radiation (albedo), in which solar rays are reflected mainly from the ground and fall on the module in a not very uniform way. The performance of the back of the bifacial module depends on a series of external factors such as:

- Distance of the module in relation to the surface (ground, roof or slab, for example);

- Tilt of modules;

- Degree of surface reflectivity.

Therefore, it is common to find datasheets (data sheets) of bifacial modules (Figure 2), a variation of the main points of the IV and PV curves according to the energy gain at the back of the module. Generally this gain varies from 5% to 30%. Therefore, although the bifacial module always produces more energy than a conventional one, the energy gain varies due to several external factors.

![Figura 2: Datasheet de uma família de módulos bifaciais com destaque para a variação dos pontos principais das curvas I-V e P-V [2]](https://canalsolar.com.br/wp-content/uploads/2020/10/datasheet-de-uma-familia-bifacial-1030x707-1-300x206.jpg)

With so many factors that affect bifacial gain, it is important to note that during the operation of a system with bifacial modules, it is likely that the bifacial gain will differ between modules throughout the day. Modules closer to the ends of the lines (as shown in Figure 3) should receive a greater irradiance reflected from the surface. Thus, in a string, we will have modules with different irradiance values. The IV and PV curves of this string must follow a partial shading pattern.

It is interesting to note that even without any shadow on the system, it is possible that it is under partial shading conditions. Therefore, with the increased use of bifacial modules in systems, an increase in the use of solutions for strings with different levels of solar irradiation is expected, among which we can highlight power optimizers. Optimizers are equipment connected directly to the photovoltaic modules, fixed to their frame on the rail, which have an MPPT tracker for each module. For a better understanding of how optimizer technology works, it is recommended to read the article Understand optimizers for photovoltaic systems. The optimizers, in addition to important benefits such as security and individual monitoring, are capable of making all modules work at their maximum power individually. So, in a string with bifacial modules without using optimizers, all modules will be limited by the one that receives the lowest irradiance at the back. However, if this same string features bifacial modules with optimizers, each module will generate maximum energy throughout the day, and no module will be limited by the other. A simulation study tested some photovoltaic systems in scenarios with different values for external factors [4]. The objective of the study was to analyze the difference in generation from the back of the installed bifacial modules. One example is 7 tracker tables (1 axis) with 20 modules. The simulated tables shown in Figure 4 feature modules in portrait position, 20 meters long, 2 meters high, 6 meters pitch, 1.7 meters high in relation to the ground, and 0.2 ground albedo.

![Figura 4: Simulação de 7 mesas com 20 módulos bifaciais cada em um sistema com tracker de 1 eixo [4]](https://canalsolar.com.br/wp-content/uploads/2020/10/simulacao-de-7-mesas-com-20-modulos-bifaciais-692x572-1-300x248.jpg)

The ground albedo level of 0.2 is a level close to that of a ground covered with grass or low vegetation. The study analyzed how much energy each location on the tracker table receives annually, as can be seen in Figure 5.

In Figure 5, it can be seen that the yellow region received the highest amount of energy in the year: 2025 kWh/m². While the purple region received 1875 kWh/m². A difference of 8% from the lowest generation to the highest generation. It is interesting to note that the largest generation is found at the ends of the table.

Conclusion

It is important to understand that the application of bifacial modules increases the generation of the photovoltaic system, providing more energy generated per square meter. However, with the application of this new technology, a generation difference problem arises between the modules of a string. Therefore, with the growth in the use of bifacial module technology, we will witness the joint growth of power optimizer technology to solve the problem.

References

- [1] International Technology Roadmap for Photovoltaic (ITRPV) – 2019 Results. VDMA. 11th Edition, April, 2020.

- [2] Risen Solar. Jager Plus RSM-6-395BMDG-420BMDG, 2020.

- [3] https://soltec.com/pt-br/single-axis-solar-tracker. Accessed on 09/30/2020.

- [4] Deline, C, Ayala Pelaez, S, MacAlpine, S, Olalla, C. Estimating and parameterizing mismatch power loss in bifacial photovoltaic systems. Prog Photovolt Res Appl. 2020; 28: 691–703. https://doi.org/10.1002/pip.3259

new RDStationForms('interesse-em-cursos-articles-do-canal-solar-2a68fc32cce5530fe808', 'UA-145443047-1').createForm();