Power optimizers are MLPE type devices (module level power electronics) that allow individual tracking of the maximum power point (MPPT) of photovoltaic modules.

Two advantages of optimizers in photovoltaic systems are well known: reducing losses due to module power mismatch and increasing the system's immunity to shadows.

Power mismatch occurs because the string modules are not identical. Even using modules from the same manufacturer, model and power, there are always slight differences between them.

These differences can cause losses of a few percentage points in photovoltaic installations.

The individualization of modules provided by optimizers makes it possible to mitigate the effect of mismatch, enabling greater energy generation.

Design flexibility

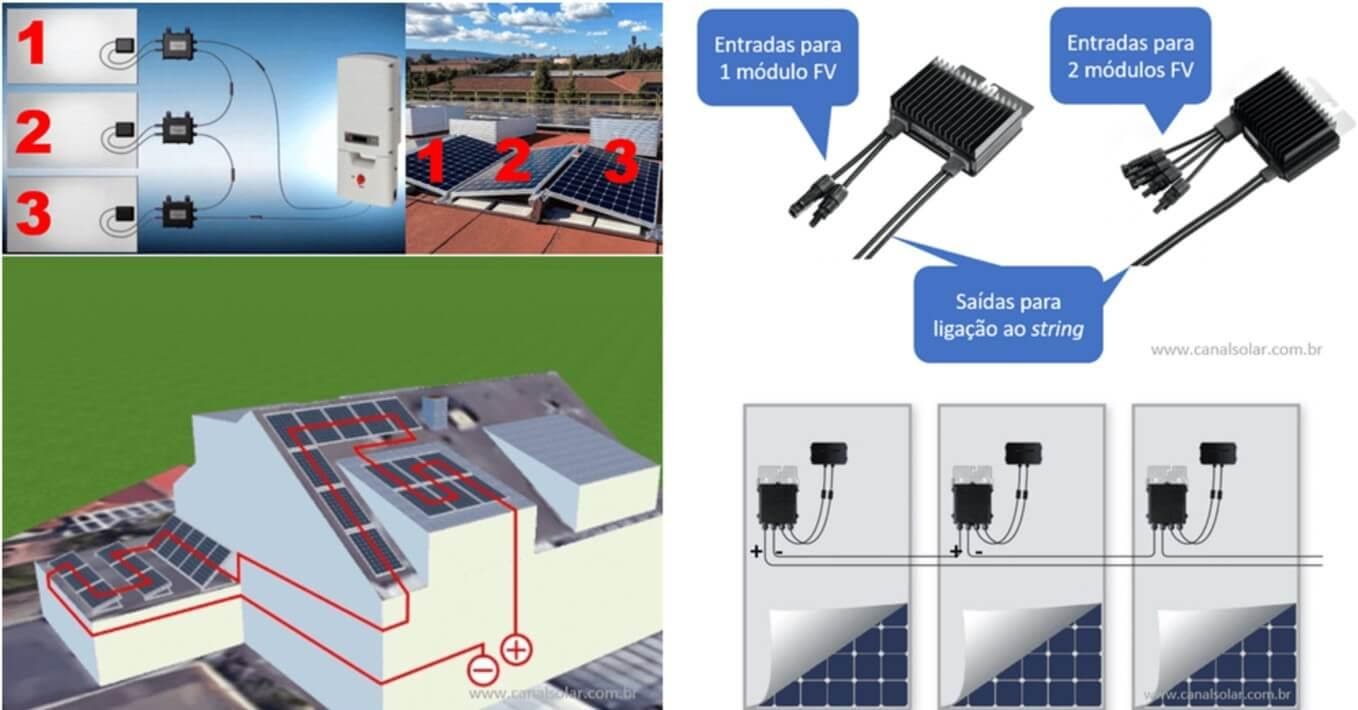

In addition to the known advantages, the use of optimizers allows configurations such as those shown in Figure 2, in which the different modules are installed with different inclinations and orientations. This type of series connection of modules would be impossible with conventional string inverters.

The architecture of photovoltaic systems with power optimizers provides efficient use of all available space on a roof. A wide variety of string lengths is possible, without the need to create strings of the same size or with modules under identical operating conditions.

Shaded modules do not harm the performance of the set and modules with different nominal powers, formats and installation methods can be mixed in the same string, as shown in Figure 2.

Figure 3 shows a practical example of a project made possible by power optimizer technology. It is a complex roof, with water in different orientations and inclinations, with limited space and the presence of chimneys. The project was installed in Italy and has 1 three-phase 5 kW inverter and 23 power optimizers.

Power optimizers eliminate several of the challenges encountered in the design of photovoltaic systems with traditional inverters, among which we can mention:

- care with the open circuit voltage of the strings;

- grouping modules into strings of the same size;

- limitation of the number of string modules;

- layout concerns on shady roofs with many different waters;

- requirement for stringboxes and need for many parallel circuits.

The main layout difficulties found in traditional designs (without power optimizers) are related to the limitation of string sizes and the impossibility of mixing modules with different characteristics and different operating conditions in the same string.

Typically, designs with conventional inverters require the use of multiple inverters or inverters with multiple MPPT inputs on complex roofs or roofs subject to shading. Even so, these solutions do not provide effective results.

Other advantages

eBOS reduction

With power optimizers the eBOS costs (electrical balance of system) are reduced. The size and layout of the photovoltaic array is no longer limited by electrical restrictions such as open circuit voltage, allowing the creation of longer strings, with a greater number of modules.

BOS is the acronym for balance of system, a designation used in the market in reference to the components of a photovoltaic system, except for the photovoltaic modules themselves. The eBOS is the electrical BOS, which includes electrical cabling, connectors, protection devices and the inverters themselves.

The architecture of photovoltaic systems with power optimizers practically eliminates eBOS costs on the direct current side. Systems with optimizers have the advantage of limiting voltages in photovoltaic systems to levels close to the modules' maximum power voltages (and not open circuit voltages).

This makes it possible to further increase the number of modules that can be connected (indirectly) in series, increasing string sizes by up to 30%.

In other words, power optimizers make it possible to leverage an advantage of string inverters, which is the use of many modules in the same circuit. Overall, this helps reduce the need for parallel circuits, reducing costs with cables, connectors and protection devices.

Electrical safety with SafeDC

SafeDC is the trade name for a technology patented by SolarEdge that reduces the risk of electric shock in photovoltaic systems. During installation or when the inverter is switched off (including maintenance situations), the power optimizers automatically switch to safety mode, in which the output voltage of the PV modules is reduced to the safe level of 1 V.

For example, if there are 19 optimizers connected in series, the maximum voltage at the string terminals will be 19 V. Automatic shutdown of the modules (and limiting the output voltage to 1 V) occurs automatically in one of these situations:

- during installation, when the string is disconnected from the inverter or when the inverter is turned off;

- during emergency shutdown, when the inverter is turned off or when the connection to the AC grid is lost; when the optimizers' thermal sensors detect temperatures above 85˚C.

Arc flash detection

SolarEdge inverters have their own system to reduce the effects of faults that cause electrical arcs and can lead to outbreaks and fires. O electric arc It is one of the main causes of fires in photovoltaic systems. Its detection and interruption are an important feature that adds security to photovoltaic systems.