An efficient way to make string connections of photovoltaic modules is the strategy known as leap-frog.

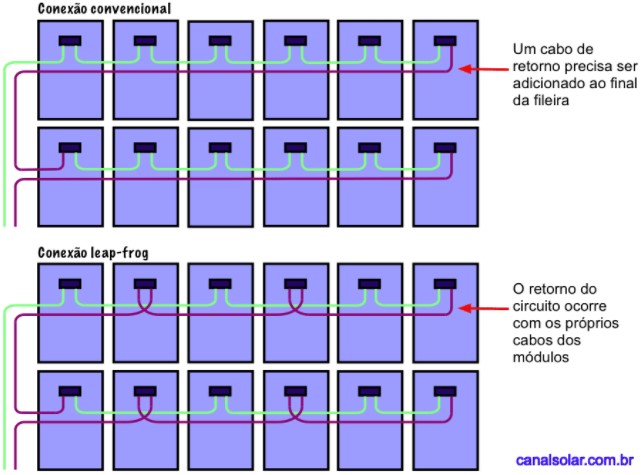

This connection mode, illustrated in the figure below, allows you to reduce the cost of electrical cables in installations.

Return and return connections are made with the photovoltaic modules' own cables, both on the return and onward journeys, avoiding the use of return cables.

In addition to providing savings, the connection leap-frog It also improves the circuit's immunity against electromagnetic induction, as this strategy forces the cables to always be close to each other, making it easier to reduce the loop areas of the circuits, which makes the photovoltaic installation less susceptible to electromagnetic surges.

How to do the leap-frog?

There's not much of a secret. Instead of connecting the modules in sequence, which is the conventional way, we connect the modules by jumping, always skipping one module. We do this on the way there and back. At the end of the connection, we return to the same point and the series circuit terminations are close together, eliminating the need to add a return cable to the circuit, as shown in the figure above.

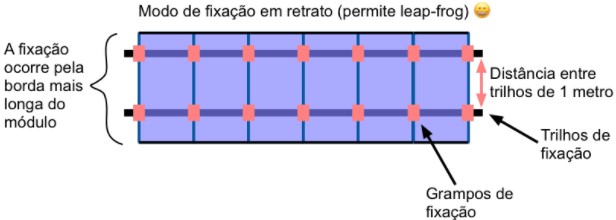

O leap-frog Is it always possible? Yes, almost always. Typically the strategy leap-frog It is possible in the vast majority of projects, as manufacturers recommend that the mechanical fixation of the module be done on the largest edge. Therefore, the mechanical arrangement shown in the figure below is always the most commonly found in any type of installation.

The actual orientation of the modules on the roof will depend on the positioning of the aluminum profiles, which can be vertical (if they are supported on the purlins) or horizontal (if they are supported on the corrugations of the tiles) – in general, that is it. However, with horizontal or vertical rails, the modules will always be flanked by the longest edge, as we see in the previous figure.

In ground-floor plants, portrait positioning (standing modules) is more common, as this eliminates the use of aluminum profiles, with the modules being supported directly on galvanized steel beams. The call leap-frog It is almost a rule today in installations, as it is uncommon to find modules flanked by the shortest edge.

What would be the impediment to making the call? leap-frog with modules flanked by the shortest edge? If you can't see this, imagine in the previous figure the modules lying on the same rails, which are in a horizontal position.

It would be difficult to interconnect the modules by skipping a module, as the distances between the modules would be longer. In the figure, while the distance between two modules is approximately 1 meter (which is the width of a module), in landscape position the distance between two modules would be 2 meters, making it unfeasible to connect modules with their own cables.