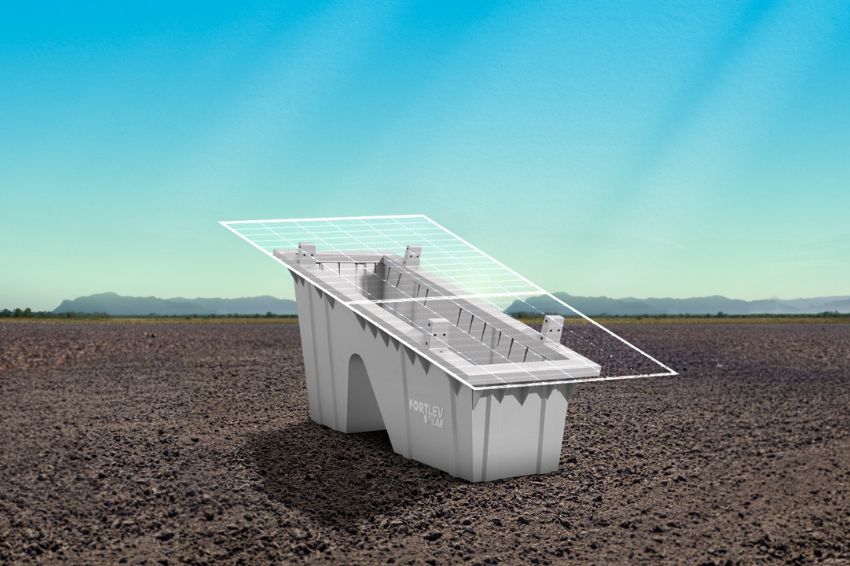

A Fortlev Solar launched, last Thursday (22), a more economical and practical structure alternative for the construction of plants on soil or slabs. The technology, called Solar Ballast, is now available to integrators.

For Eduardo Nascimento, engineering manager at Fortlev Solar, the main advantage of the solution is the reduction in installation time. “Compared to a metallic ground structure, the Solar Ballast has a 50% reduction in assembly time”.

“For example, the average installation time for a 100 kWp plant, with 185 modules, is 14 days. With Solar Ballast, this time is reduced by half. By installing faster, the return is also faster”, he analyzed.

Among other benefits listed by the engineer are facilitated logistics, labor savings, reduced waste on site and the flexible mobility allowed by the ballast, which is not fixed to the ground. “This simplifies the demobilization of a plant”, he highlighted.

“In the dynamic world we live in today, land becomes instantly valued, opening up business opportunities. Therefore, in the future, if there is the possibility of selling or building on the land, it is possible to move the plant”, added Nascimento.

According to the company, as it is resistant, light and easy to handle, installation becomes simpler. Maurício Ouriques, engineer responsible for developing the Solar Ballast, emphasized that this was a pillar in the design of the structure.

“The idea was to produce something simple that anyone could assemble, thus reducing labor costs”, recalled Ouriques.

From a commercial point of view, Fortlev Solar's engineering manager stated that the solution has a significant advantage compared to conventional structures.

“The integrator who opts for this type of technology comes out ahead of the competition, because adding capex, labor reduction, material reduction, plus the seven days, the gain is more than 10%” he explained.

How Solar Ballast works

The new solution for floor or slab plants is made of polyethylene, weighs 15 kg and has high resistance. The ballasts are filled with earth, sand, gravel, concrete or similar to support the structure, to which the profiles and modules are fixed.

According to the company, the equipment has a tilt adjustment system and should preferably be used on clean, fenced land.

know more about How does Solar Ballast work?.

Fortlev Group know-how

Patented by Fortlev Solar, the Solar Ballast is made of 100% polyethylene, a material used in the production of Fortlev water tanks. The Group, which has been in the market for over 30 years, highlighted that it used its expertise to bring a product that further expands the accessibility of solar plants across Brazil.

“Fortlev is one of the main manufacturers of water tanks in Brazil, which makes us experts in the production of thermoplastics and the rotational molding process. We are not venturing out. We created a quality product with the credibility that the Group offers”, concluded Maurício Ouriques.

Service

According to Fortlev Solar, to purchase photovoltaic kits with the Solar Ballast, simply access the application: fortlevsolar.app or speak to a company consultant via Whats-App: https://wa.me/552734414160.

One Response

Good afternoon. We visualize this framework solution. I would like to know more information about her.

We are starting a ground plant project and this type of structure would be ideal for implementation.

Could you help us please.