A fire in East Hope, Chinese manufacturer of polysilicon, should stop production for about a month. It is estimated that the stoppage will affect the production of 2,500 metric tons of polysilicon. Altogether, the factory has a capacity of more than 70 thousand metric tons.

O polysilicon is the main raw material for the manufacture of poly and monocrystalline photovoltaic cells.

AThe information is from International Energy Network, Chinese news agency on the photovoltaic market.

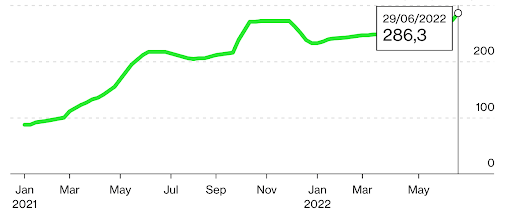

According to a note released by China Silicon Industry Association, this incident already reflects on the price of modules.

“This week's increase in the price of polysilicon is mainly due to an unplanned maintenance outage of a company in Xinjiang [East Hope], which led to the sudden halt of some of its long-term orders. With the increase, three new companies plan to reshape the quarter. To summarize, the price of silicon material continued to rise sharply this week,” stated in a statement.

Also according to the association, the average transaction price for polysilicon is 42.73 US$/kg. At the beginning of June, according to the China Silicon Industry Association, the average price was 39.74 US$/kg.

“What happened ends up putting even more stress on a production chain that is under pressure due to the difficulty of supply concomitant with high demand. We see a challenging scenario for the second half of the year given that there is typically an increase in the pace of project installations in China during this period, weighing on the demand side”, said Felipe Santos, LATAM Products Manager at Canadian Solar.

Photovoltaic industry

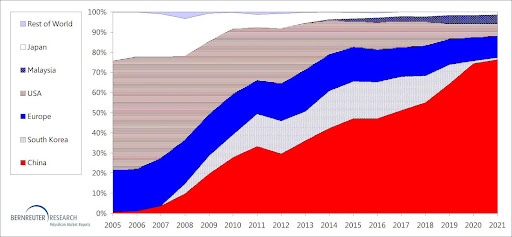

Second The Bernreuter Research – North American research company for the polysilicon, photovoltaic and semiconductor industries – China dominates the production chain of polysilicon, with the seven largest manufacturers of the input having a production capacity of around 736 thousand metric tons per year.

According to the latest survey, this amount from Chinese companies corresponds to more than 70% of world production.

O latest survey by Bernreuter Research, shows that China produces more than 600 thousand metric tons, with East Hope responsible for 70 metric tons per year and is the fifth manufacturer in the ranking of the largest polysilicon manufacturers in China. See the largest polysilicon manufacturers.

- Tongwei – 205,000 metric tons;

- GCL Technology – 140,000 metric tons;

- Daqo New Energy – 140,000 metric tons;

- Xinte Energy – 100,000 metric tons;

- Xinjiang East Hope – 70,000 metric tons (company that recorded the fire);

- Asia Silicon (Qinghai) – 52,000 metric tons;

- Shaanxi Non-Ferrous Tianhong – 19,300 metric tons;

Understand the fire

The fire hit the factory on June 17 and, according to Chinese media reports, was caused by a leak from a super heater in the hydrogenation unit of part of the East Hope plant, located in the Wucaiwan Industrial Park, in the Economic and Technological Development of Zhundong, in Xinjiang, northwest China.

According to the Bernreuter Research, between the summer months in China – June to September – the risk of this type of incident increases, as the months of this season are a high-risk period for polysilicon production.

“In addition to the hot weather, polysilicon manufacturers are operating at full tilt due to supply shortages and high prices. This may loosen attention to security issues,” said Bernreuter.

Also according to Bernreuter, June is the month of national safe production in China. “On June 13 – just four days before the accident at East Hope – a group of experts from the Chinese Ministry of Emergency Management visited the factory to provide guidance and hold a symposium. Obviously, it was not enough to avoid the accident”, he informed.

Explosion at factory in China

About two years ago, two other polysilicon manufacturers also suffered accidents, and both are also located in Xinjiang: on July 1, 2020, a small fire occurred at the Daqo New Energy; on July 19, 2020, a series of explosions hit the Xinjiang GCL.

At the time, the Canal Solar showed that the price of polysilicon material increased by 20%. The increase was due to the explosions that took place at the GCL-Poly factory, in Xinjiang, China, one of the world's main producers of polycrystalline silicon.

According to the company, overpressure in the rectification and boron removal filter during equipment maintenance may have caused the leak of trichlorosilane gas, which, in turn, reacted explosively with moisture in the air.

California investment bank Roth Capital Partners also reported at the time that, following the incident, 50 metric tons of polycrystalline cell production capacity was removed, resulting in a 10% reduction in the global supply of solar energy raw materials.

2 Responses

Very useful information Ericka, congratulations on the consolidation and thanks for sharing.

It's amazing how factories in China catch fire.

In the past, they were used for memories, cards, etc.

https://www1.tecnoblog.net/meiobit/266496/fabrica-memoria-ram-china-incendio-preco-dispara/

https://www.notebookcheck.info/A-MSI-confirma-um-incendio-acidental-em-sua-fabrica-chinesa-de-PCB.503465.0.html