A collaboration between UFRB (Federal University of Recôncavo da Bahia) and Amara Energia made it possible to create a photovoltaic solar energy laboratory with the aim of carrying out studies of different technologies available in the photovoltaic sector in real conditions.

The laboratory will also be of great value to the university's academics, who will be able to carry out research, develop articles and coursework using the laboratory's structure. These structures are often not easily accessible to the academic community.

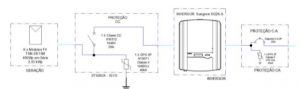

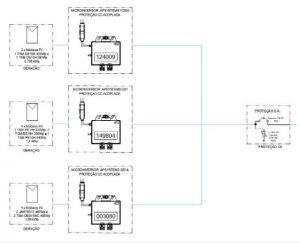

16 photovoltaic modules distributed in a string inverter (inverter A) and three microinverters (inverters B, C and D) were installed and commissioned. All inverters work in the same climatic conditions, installed on the same electrical network and with modules facing the same direction.

The three microinverters are connected close to the modules, next to the installation's fixing structure, and the inverter is housed in a covered installation with the appropriate technical needs and 10 meters away from the photovoltaic modules.

In summary, the following photovoltaic systems are located in the laboratory:

Table 1: Inverter technology and installed power of photovoltaic systems

|

Inverter |

Technology |

Installed Power (kWp) |

|

Inverter A |

String |

2,43 |

|

Inverter B |

Microinverter |

0,795 |

|

C inverter |

Microinverter |

1,4 |

|

D Inverter |

Microinverter |

1,69 |

As the objective of the laboratory is to analyze different photovoltaic module technologies, the following arrangements were carried out:

Table 2: Photovoltaic modules used in the systems

|

Inverter |

Modules |

|

Inverter A – Sungrow SG2K-S 2 kW |

6 – TSM-DE15M 405 Wp |

|

Inverter B – APsystems YC600 0.6 kW |

1 – TSM-DE15M 405 Wp 1 – TSM-DE15H 390 Wp |

|

Inverter C – APsystems QS1 1.2 kW |

1 – TSM-DE15H 390 Wp 2 – TSM-PE15H 340 Wp 1 – TSM-PE14A 330 Wp |

|

Inverter D – APsystems QS1A 1.5 kW |

2 – TSM-DEG15MC. 405 Wp 2 – JAM78S10 440 Wp |

As indicated in Table 2, the connections between modules and inverters can be better represented through the following diagrams.

For a better understanding of the laboratory's lines of research, the construction characteristics of each module present in the plant are highlighted here:

Table 3: Cell types and module technologies used in the different laboratory systems

|

Module |

Cell Type |

Type of Technology Present |

|

TSM-DE15M 405Wp |

Monocrystalline Silicon |

Monofacial; Half cell; Multibusbar and PERC |

|

TSM-DE15H 390Wp |

Monocrystalline Silicon |

Monofacial and Half-cell. |

|

TSM-PE15H 340Wp |

Polycrystalline Silicon |

Monofacial and Half-cell. |

|

TSM-PE14A 330Wp |

Polycrystalline Silicon |

Monofacial. |

|

TSM-DEG15MC. 405Wp |

Monocrystalline Silicon |

Bifacial; Half-cell, glass-glass and Multibusbar |

|

JAM78S10 440Wp |

Monocrystalline Silicon |

Monofacial; Half cell; Multibusbar and PERC |

As a result, several research studies will be carried out in the laboratory with the aim of expanding practical knowledge linked to the theory of photovoltaic systems. Initially the following comparisons will be made:

- String inverters x microinverters;

- Polycrystalline modules x monocrystalline modules;

- Monofacial modules x bifacial modules.

One cannot fail to highlight the structures used in the plant, both for soil: the Ecoground structure and a conventional single-post structure. Each structure has different configurations and parameters that deserve to be analyzed, as well as their impact on energy generation.

The following topics stand out here: height above ground, angle of inclination, spacing between rows and width between sheds. For the systems analyzed here, the height above the ground and the angle of inclination will be the preponderant factors, as discussed in the article “EcoGround Structure – Differences and advantages compared to conventional soil structures”.

For the single-post structure (Figure 6) the local inclination (13°) was used with the modules installed in portrait and for the Ecoground structure (Figure 7) the inclination of 15º (manufacturer's standard) was used with the modules installed in landscape .

With these structures, the influence of the inclination and height of the modules in relation to the ground will be analyzed for the generation of the photovoltaic system.

The effect of the presence of gravel at the installation location of the bifacial modules will also be studied, with the aim of increasing the albedo to capture greater solar radiation on the lower face of the module. Factors like these are described in more detail in the article “Albedo (reflection coefficient): definition and influence on bifacial modules”.

In summary, this laboratory will present and study the main differences between photovoltaic systems connected to the electrical grid in a practical way. The results will be disseminated to society through articles and annual reports regarding the generation and efficiency of each system analyzed.