Recently, in Brazil, the installed capacity of photovoltaic solar energy surpassed the 32GW mark, including both centralized generation plants and own generation systems, on rooftops or small plots of land.

The rise of technology in a short space of time is notable, given that at the end of 2017 there was just over 1GW of installed power.

In this scenario of accelerated growth, it is expected that doubts will arise regarding the correct use of system components and how to extend their useful life, and it is the manufacturers' role to guide which preventive procedures are required by their equipment over 25 years or more of performance. guaranteed.

Cleaning photovoltaic modules is one of the essential topics related to maintenance, after all, as the equipment is continuously exposed to weather conditions, it has the highest probability of accumulating dirt which, when deposited on the module's glass, can considerably reduce the output power and compromise energy production.

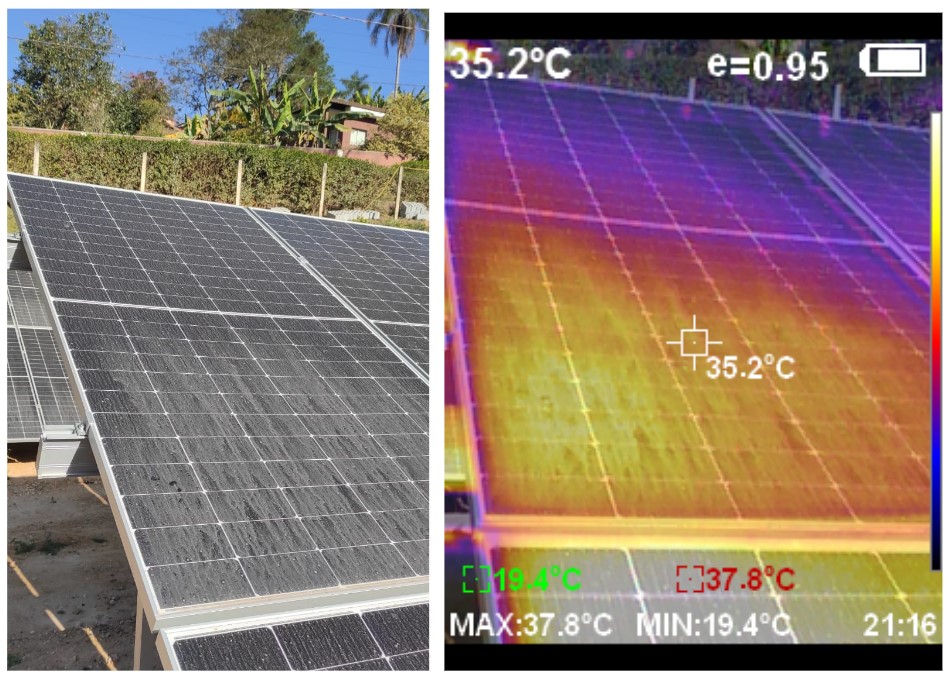

Below are photos of a module with dust and the corresponding image taken using a thermal camera. The difference in the module's operating temperature between the upper and lower parts is notable and, on a color scale, the stronger the yellow, the lower the capacity to absorb sunlight and, therefore, the lower the current generated when compared. to blue tones.

JA Solar, one of the largest photovoltaic module manufacturers in the world, has a series of explanatory videos on Youtube that demonstrate, through a creative and succinct approach, the main themes related to the panels, including what care needs to be taken during installation.

It also has a specific manual for cleaning, full of instructions on how to carry out this task, which will be explained in detail. Firstly, it is important to highlight that the inclination of the modules favors the natural drainage of dirt through rain, with 10 degrees being the recommended minimum.

Furthermore, it is necessary to analyze the environment in which the installation is located, in order to determine the cleaning frequency: more arid locations, far from urban centers and close to land, may require a monthly periodicity, while residential installations, where there is recurrent rain , once or twice a year is sufficient.

As dirt is easily detected through visual inspection, this technique helps to define a schedule that suits the location.

Essential safety recommendations need to be followed, such as choosing the ideal time, which is during periods of low irradiance, at the beginning or end of the day or even at night, as the module's surface temperature is lower and, consequently, the DC current values will be lower and there is less chance of a possible thermal shock occurring between the water from cleaning and the module glass, avoiding possible breakages

Furthermore, the professionals responsible for cleaning must be chosen carefully, with technicians who are able to carry out work involving electricity and heights being a good option.

To avoid any and all types of accidents, it is extremely advisable to use the correct PPE (see NR10 and NR35). Regarding the tools that can be used in the process, JA Solar recommends the use of soft materials, including: foams, dusters, sponges, brushes and fabrics, as well as window squeegees.

On the other hand, abrasive metallic instruments, such as knives, blades and steel sponges are prohibited, because when they come into contact with the glass, the friction can scratch it and cause damage that will not be covered by the equipment warranty.

For larger plants, where manual cleaning is inefficient, it is common to use automated machines for this purpose, however, due to the diversity of models on the market, it is preferable to contact JA Solar's technical support to assess possible compatibility. .

There are also restrictions on the products that can or cannot interact with the modules, as they have an anti-reflective layer deposited on the glass that can be corrupted if there is contact with alkaline or acidic materials, such as stain removers.

Other harmful examples are chemicals such as sodium hydroxide, benzene, nitro diluents, therefore, all of these mentioned must be excluded from the activity.

So, the question remains: What can be used?

Usually, just water is sufficient, as long as it is at a pressure lower than 690kPa (100psi), however, if there are stains that are more difficult to remove, such as animal waste, washing with neutral soap or any commercial glass cleaner is permitted. , ethanol, methanol and alcohol.

Table 1: Items allowed or not in the washing process

Finally, you should never step, sit or stand on the modules, as including visible breaks, body weight can cause microcracks at a cellular level that are invisible to the naked eye. Furthermore, as a precaution, it is advisable to disconnect the installation inverters or the stringbox disconnect switches.

At the end of the cleaning process, after dusting, scrubbing and washing the modules if necessary, why not carry out an inspection of the plant? To ensure proper functioning, it is worth checking whether there are signs of breakage in the glass, corrosion in the cells, whether the junction boxes show traces of sparks or burns, whether the cables have no signs of rupture and whether the connectors are crimped correctly.

Photovoltaic systems in general require a simpler and cheaper level of maintenance when compared to other generation sources, however it is essential to carry out the steps described to guarantee their efficiency and at the end of the month, a loss-free energy bill!

The opinions and information expressed are the sole responsibility of the author and do not necessarily represent the official position of Canal Solar.

2 Responses

Great approach, very objective. Gratitude.

Good morning, very good explanation!