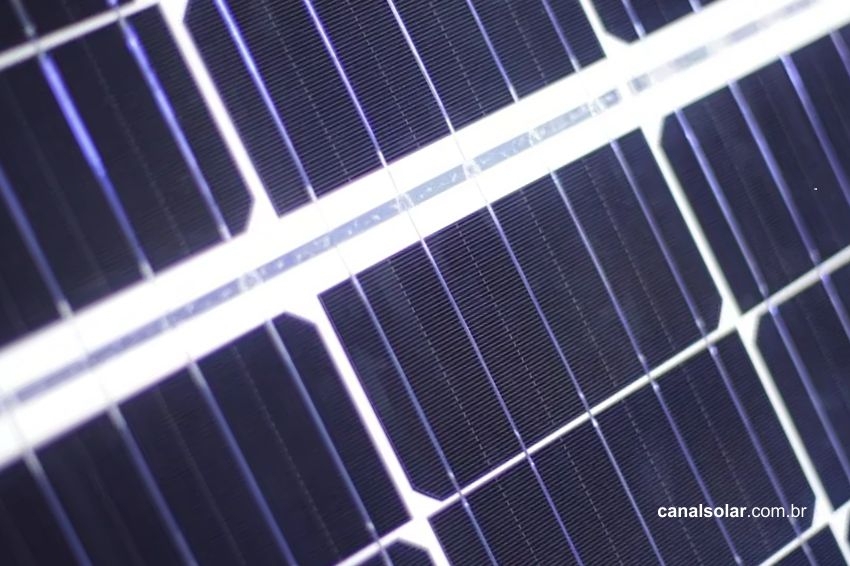

The technology half-cell consists of building photovoltaic modules with cells cut in half. Instead of traditional square cells, rectangular cells are used.

What is achieved with this are more efficient modules with approximately the same dimensions and the same cost as a common module.

Furthermore, cells with reduced dimensions suffer less mechanical stress, being less subject to the origination of microcracks (micro cracks), one of the main causes of reduced efficiency and useful life of photovoltaic modules.

Cells are already supplied cut in half by cell manufacturers. For module manufacturers, the production process with cells half-cell It is very similar to that of common cells, with only small adjustments required to supply the production lines with one type of cell or another.

Rectangular (rather than square) solar cells are not new to the family of polycrystalline modules. The innovation that has only now reached the market are modules based on monocrystalline cells half-cell.

While polycrystalline cells can already be manufactured in a rectangular shape, monocrystalline cells (because of the crystalline ingot manufacturing process) can only be manufactured in a square (or originally circular) shape.

To product half-cells rectangular cells it is necessary to use a process to cut the square cell, which is not so simple. Cutting can be done by mechanical or laser processes.

The TLS laser cutting method (Laser Thermal Separation) allows cells to divide without virtually any mechanical damage.

Several manufacturers are offering modules with 144 cells, which are the half-cell of traditional 72-cell modules.

The most efficient modules found commercially today, surpassing 20%, are the mono-PERC with cells half-cell bifacials.

144 or 72 cell modules are very similar, with very similar mechanical and electrical characteristics. What do you gain from half-cells it is an increase in the efficiency of the module, as we will explain below.

Increased efficiency

Cells cut in half produce half the electrical current of a conventional cell, since electrical power depends on the square of the current.

With half the current circulating in each cell, the ohmic losses in the electrical terminals and contacts and in the cells themselves are reduced to 1/4 of the original losses, as the module's ohmic loss becomes P = R (i/2)2 = laugh2/4, whereas originally the losses would be P = Ri2, assuming that the ohmic resistances present in the modules are approximately the same for both types of cells.

Increasing module efficiency half-cell it is also higher due to the spacing between the cells, which increases optical efficiency by allowing greater scattering of the light that falls on the cells.

Shadow tolerance

Modules half-cell have greater shadow tolerance than traditional modules. The figure below shows what can happen in two different modules (half-cell and standard) when subject to the same shadow.

The division of cells into a greater number of groups, as occurs in modules half-cell, allows you to decouple the effect of shadows when they fall on only certain parts of the modules (partial shadows).

Thermal performance

In conventional photovoltaic modules there is a single junction box that contains several electrical connections and typically houses three diodes bypass.

With the distribution of circuits of a module half-cell, as we see in the figure below, it is necessary to distribute the bypass rather than confining them to a single box.

The presence of multiple junction boxes (junction box) also ends up being a positive aspect, as this reduces localized heating caused by the presence of junction box.

Experiments show that the temperature of the module junction boxes half-cell could be 15OC to 20OC smaller than that found in the single junction box of conventional modules.

The reduction in the current flowing through the ohmic resistances, also halved in each half cell, causes heat dissipation to be reduced.

In the event of hot spots, a phenomenon that arises when there is reverse current circulating through the modules, the temperature rise will be reduced, reducing the risk of damage to the modules or fires.

In general, the circulation of currents of reduced intensity improves the thermal performance of the module overall, not only with regard to reverse current, but also during normal operation.

Features of commercial modules

In the table below we see the STC characteristics (Stardard Test Condition) and NOCT (Nominal Operating Cell Temperature) of a commercial photovoltaic module.

The output voltages and currents are approximately the same (i.e., of the same order of magnitude) as would be found in a conventional module.

If all the half cells were in series, the module would have twice the voltage of a common module, with half the current.

However, as we saw previously, the cells cut in half are grouped into two parallel sets within the module, each with 72 half cells in series (in the 144 cell module) which makes the total voltage and current (obtained in the module terminals) are compatible with those of conventional modules.

The table also reveals the module's low thermal coefficient (-0.36%/OC) compared to conventional modules (typically above -0.38%/OW).

Table 1: STC and NOCT characteristics of Jinko's Cheetah HC 72M modules

One Response

In an increase in energy generation in a Photovoltaic system where the majority of panels are (8), I can increase by (4), in the same string respecting the Voc and Vmp limits of the inverter.