Niobium is a metal, extracted from the pyrochlore ore, with atomic number 41. It belongs to the fifth period of the periodic table, therefore considered a transition metal, and is in the same family as Tantalum.

It is a relatively new material, it was discovered in mid-1846 and began to be used around 1950. When added to metallic alloys, such as steel, it gives them ductility, making them capable of undergoing deformation without breaking.

It became known for being frequently cited by President Jair Bolsonaro as promising, because Brazil holds around 94% of the entire world niobium reserve and is responsible for another around 90% of the material's extraction.

Despite this reputation, currently niobium is practically all exported at low cost to other countries that apply niobium and resell it to us.

Regarding the advantages of niobium, it has high thermal and electrical conductivity, ductility, malleability and high resistance to heat, wear and corrosion. These characteristics provide the ability to improve the properties of materials, making them more efficient. As a result, the metal is currently applied to several sectors, with important technological contributions.

Among the segments that it can bring benefits is energy. According to the CBMM (Companhia Brasileira de Metalurgia e Minação), niobium is very promising for this market, especially for batteries.

“Niobium will not replace lithium, but rather will be applied in lithium batteries. In this case, it can replace or reduce the use of nickel and cobalt. We work, for example, in the development of niobium technologies for the cathode and anode of batteries”, said CBMM.

“There are several other lithium batteries, but the insertion of niobium represents potential for safety, durability and ultra-fast recharge capacity (in less than 10 minutes), without loss of life cycle”, they highlighted.

The Senai Institute for Innovation in Electrochemistry also discussed the subject and highlighted that the metal guarantees more efficient storage solutions to guarantee a future powered by renewable electricity.

“In battery projects containing niobium, solid electrolytes with high conductivity of lithium ions are produced, producing batteries of the 'all solid state' type, that is, without liquid, which is potentially flammable”, they pointed out.

These technologies, according to the institute, are called next generation batteries. For this development, an international level infrastructure that also includes a pilot plant for the production of lithium batteries and a team of researchers with doctorates, masters and graduates, is the pillar for the success of the results obtained.

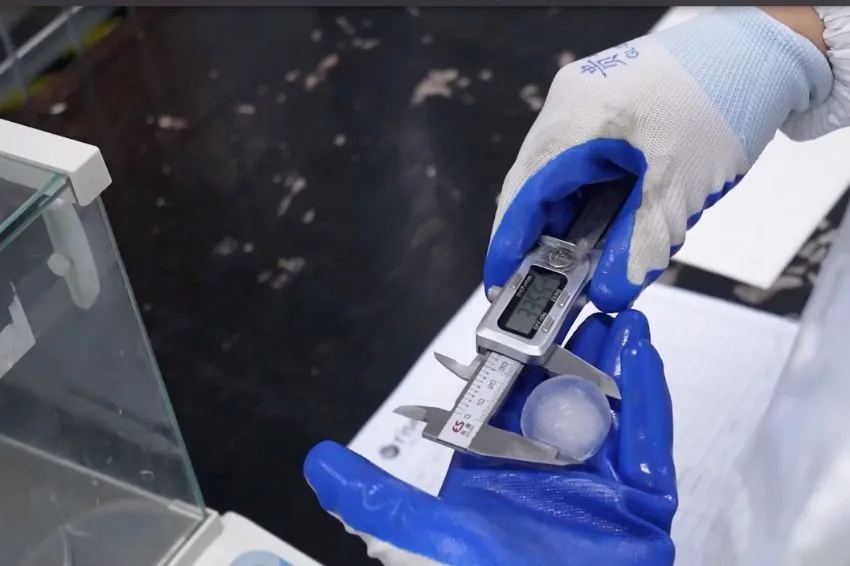

The first prototypes of niobium-containing battery technology produced at Senai in partnership with CBMM were presented at the 1st Brazilian Niobium Fair, which took place in October 2021 at CNPEM (National Center for Research in Energy and Materials), during the inauguration of SIRIUS , a Synchroton-type particle accelerator in Campinas (SP).

“The big challenge is to produce prototypes with greater capacity for application in an operational environment, mainly in electric vehicles”, concluded the research group.

Application in hybrid vehicles

CBMM emphasized that an extremely positive feature of this technology is, precisely, the high capacity to receive load from the cars' braking systems, thus making it a very competitive solution also for hybrids due to its potential to reduce fuel consumption.

“Niobium batteries, in a medium-sized vehicle, can achieve ranges of approximately 350 km. With just six minutes of charging, the car will once again have another 350 km of autonomy”, they reported.

This high recharge capacity is also reflected in the car's power system, so they can achieve much higher levels of acceleration in a short space of time without reducing the battery's useful life.

“When the batteries are no longer sufficient for a vehicle, they can be reused in photovoltaic solar panels, wind turbines, etc.”, they concluded.

Niobium-Based Batteries for EVs

WVCO (Volkswagen Caminhões e Ônibus), in partnership with Companhia Brasileira de Metalurgia e Mineração, formalized an agreement to develop and manufacture niobium-based batteries for EVs (electric vehicles), allowing them to be charged in up to six minutes.

According to Volkswagen, the technology that will be used in the batteries is the result of more than three years of research carried out in conjunction with Toshiba. The start of operations will be dedicated to electric buses.

VW stated that it will begin testing this year and also expects that a functional electric vehicle model using niobium-based batteries will be ready by the end of 2022.

More about niobium

Niobium is not rare. In addition to Brazil, there are more than 85 ore deposits that can be transformed into niobium, in places such as: Russia, Canada, Greenland, Angola, Gabon, Kenya, United States of America, China, Saudi Arabia, Australia, Tanzania, Democratic Republic from Congo, Finland, Malawi, Norway, South Africa, Zambia, Namibia, India, Spain and others. In other words, it is not correct to say that Brazil has mineral reserves that can be transformed into niobium.

“Brazil's representation in the global market is due to the development of this market, led by a Brazilian company, which has invested for more than six decades in technology and applications for niobium products in various sectors”, concluded CBMM.

Other applications of niobium

Among its commercial uses, we can mention its use in medical devices, such as pacemakers, as its metallic alloys are physiologically inert and have hypoallergenic characteristics. For this reason, it is also used in the manufacture of jewelry.

Niobium is also used in the production of superconducting magnet wires used in magnetic resonance machines and even particle accelerators.

5 Responses

let's see what happens

LiFePO4 (Lithium iron phosphate battery) batteries are already a reality on the market and are equipped with some Tesla models. The world's largest supplier of batteries for electric cars CATL (Amperex) is expected to offer an industrial-scale battery for 1000 km in 2023 with a charge time of 80% in 10 minutes. LiFePO4 batteries allow up to 10,000 charge cycles, around 3x more durability) and are cheaper than current batteries. LiFePO4 material has low toxicity, does not use cobalt, manganese or nickel and is intrinsically safe as the material is stable. In other words, it will be very difficult for niobium batteries to compete with what is already on the market today.

The report is very interesting. I would like to receive more information.

Brazil's niobium (reserves), solid-state lithium batteries (less explosive), the shortest recharging time (6 min), the longest recharging range (350km), the highest number of battery cycles and also the possibility of final reuse of the battery in wind and photovoltaic energy. Niobium, highly promising Brazilian metal. Congratulations.

I am an enthusiast of this technology.