A constant doubt for photovoltaic system integrators is linked to the installation of the string box.

With a worrying frequency, we find incorrect installations in which the polarities of the cables are mounted inverted, a situation that could be avoided through simple electrical tests that professionals in the field must carry out during the commissioning of the systems.

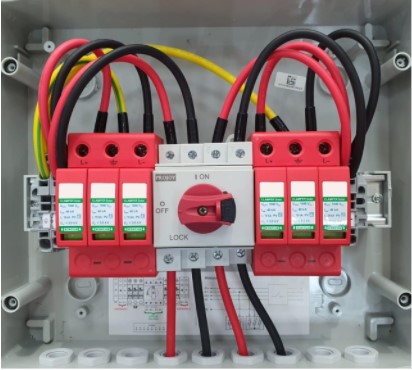

When purchasing the various pre-assembled string box options available on the market, integrators typically encounter great difficulty due to the variety of standards adopted by manufacturers.

It is common for string box manufacturers to have their own particularities and to have manuals and explanatory diagrams for the use of their equipment. However, negligence by some installers may cause the system to fail to boot.

When the system fails to start, the integrator generally seeks to attribute the problem to other components, such as the inverter, without paying due attention to all aspects of the project.

Polarity inversion can occur as a result of a simple mistake in making the connections that start at the modules, pass through the string box and end at the inverter.

Some brands of inverters available on the market even warn about the failure through their displays. However, many models use their own connection to solar panels to power their electronics.

When inverted, they do not work and generate dissatisfaction among the installer and waste of time during installation due to the search for a solution to the problem. In addition to these situations, it is possible to run the risk of inverting the polarities between the photovoltaic arrays, breaking the voltage limits of the modules, the string box or even the inverters.

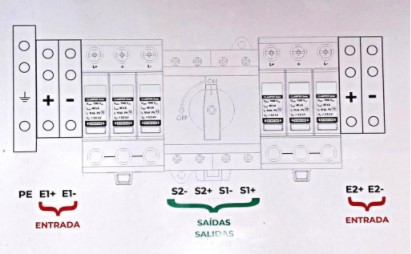

To avoid this type of occurrence, it is interesting to carefully study the diagrams and manuals that accompany the string box and identify the particularities between terminal connections, DPS, disconnector switches or fuse bases.

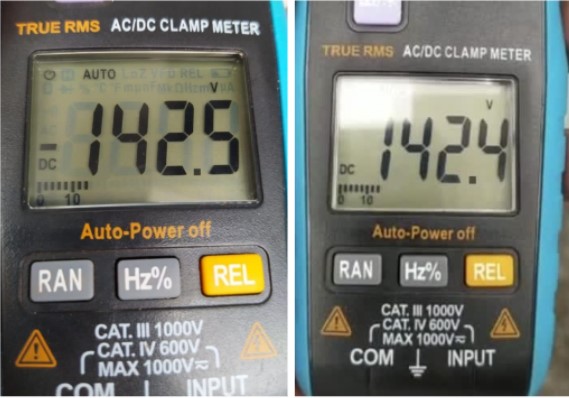

In addition, measurements must be taken with a multimeter at each point of the connections to confirm that the voltage values and polarities are adequate at the inputs and outputs of the components.

A practical example of the situation mentioned above consists of building a string where the modules have an open circuit voltage of 45.84 V. With a string of 10 modules we will have a total voltage of 458.4 V. Small variations are expected due to external factors such as temperature, orientation and inclination.

It is also important after this step that the professional pays attention to the correct values presented in the multimeter reading and the polarity when connecting the string box. A reading of -447 V indicates an acceptable voltage drop, but reverse polarity in relation to the multimeter probes.

Another recurring situation occurs when the connection pattern in a string box changes in relation to the models used by the installer, familiar with another supplier.

Some manufacturers use equipment such as bipolar disconnector switches with direct passage, while others use tetrapolar switches with crossed outputs, which, when falling into the hands of an inattentive professional, can generate an inversion in the polarities at the output of the string box, which can be avoided by means of a new reading of potentials and polarities.

After leaving the string box and passing the cables, a final reading of the corresponding parameters is interesting.

The construction of monitoring and measurement processes throughout the installation of photovoltaic systems proves essential in order to avoid risks and discomfort for integrators and their customers.

The use of suitable materials and equipment, such as a multimeter with complete clamp meter, capable of carrying out measurements in direct and alternating current on the project scales, will be the necessary assistance for a good installation.

Distributors have a technical team prepared to assist integrators and ready to answer any questions that the installation professional may have.

One Response

Congratulations on the very enlightening article, installers really need to pay attention to these details.