The Brazilian solar sector is rapidly developing and therefore it is necessary to invest more and more in training of our technicians and professionals in the installation sector, maintenance and repair, as well as technical standards for this sector. Regarding training, we can increasingly find good institutions willing to train and qualify professionals.

However, in the midst of crises and uncertainties experienced, professionals do not always have the resources to invest in improvement and thus, the sector becomes vulnerable, with low quality professionals and technical knowledge, in a competitive market, however, with quality and service to technical standards sometimes neglected.

In this scenario of great growth, as at all times, supervision by class entities, such as the CREA (Regional Council of Engineering and Agronomy), should be more active, thus ensuring full compliance with technical standards.

Each project always has a ART (Technical Responsibility Note) and a responsible professional, but not always, or almost never, the systems are actually inspected and properly commissioned, however it is known to all technicians and designers that all solar installations must comply with current NBR standards such as NBR 5410, NBR 16690 , NBR 5419, NBR 16274, IEC 62548, IEC 63227, IEC 60947-1,2 and 3, IEC 62109-1 and 2, among many others.

See too

ART is no longer mandatory in DG projects?

Watch: Webinar | Does every solar energy company need to be registered with Crea?

There are different aspects in which equipment must protect installations, but in truth we believe that good projects, trained professionals, supervision of compliance with technical standards, are complementary to the intrinsic protections of equipment and not exclusive.

Let's take, for example, the service NBR 16690 which is often not properly interpreted and followed. On the contrary, several professionals and equipment manufacturers and/or integrators of photovoltaic solutions and/or kits are expressing their own opinions instead of following technical standards.

We believe that several of you have already come across expressions: free of fuses, no need to use a string box, no need to use an external DPS, etc. However, we forget that the owner of the project or the person technically responsible for the project is not institution A, B or C, but the person actually responsible for the project to be implemented is the technician/engineer.

It should also not be news that many designers carry out projects for themselves and not for the people who will actually execute them. The project must be executed in accordance with ABNT standards, following the NRs, but focusing on the executor, who is often a beginner electrician, a technician with little experience, a technician with a lot of experience or a E=qualified company.

However, the project must be understood by its target audience and always in accordance with current standards, independent of personal interpretations or interests.

During a presentation, we asked a group in training who had already read and interpreted NBR 16690, and who would not ask about the NBR 5410 Or the NBR 5419, understanding that just like the NR-10, these were basic and worthy of being at the designer’s bedside and easy to consult.

To our surprise and perplexity, less than 10% of future designers claimed to know NBR 16690 and around 50% had already read part of it or participated in webinars about it.

NBR 16690:2019 – Electrical installations of photovoltaic arrays — Project requirements came to regulate and regulate photovoltaic arrays and thus be understood and applied.

Many of the current inconveniences experienced in various installations and fire risks could be avoided or minimized if NBR 16690:2019 was applied. As for the risk of fire in photovoltaic parks, these are rare, but we have several other problems that occur, whether in the design, installation or commissioning phase.

Contrary to those who say that NBR 16690:2019 only deals with string boxes, DPS, it goes much further and provides us with guidelines regarding conductors, electrical protection devices, switching devices, grounding and equipotentialization of the photovoltaic array.

Another point that must be very well observed is that this standard deals with arrangements between 35 and 1500 V in direct current (Vcc) and, this is complementary to NBR 5410, which deals with systems of 1000V alternating current and systems of up to 1500V in direct current.

Therefore, even with an immense desire to include personal opinions that the electrical equipment to be used in photovoltaic systems from manufacturers A, B, or C allow use up to 1550 or 1580 Vdc, please note that the standards do not describe or do not apply to systems above 1500 VDC and therefore, we cannot apply them.

When we then mention the standards that served as the basis for the preparation of NBR 16690, we have more than two pages of reference and a range of fuses, electrical panels, grounding systems, among others.

This current standard is so strong and at the same time misinterpreted and followed, that if investors, investment funds and/or insurance companies dedicated a few days and hours to understand it, many projects would lose their investors or their insurance companies for understanding the risks. , veiled or direct to which they are exposed and, in this way, making the projects high risk and low attractiveness.

Every engineer acting as an expert, in the case of an arbitration or expert opinion, could have arguments based only on NBR 16690:2019 to perhaps, in the event of a claim, propose to the insurer not to pay the insurance premium, since the expected as a rule, it was not properly implemented and this not only in the case of adopting a main equipment such as a photovoltaic inverter, but also when choosing a conductor that does not comply with the maximum current or in the absence of an element overcurrent and/or reverse current protection. Again, the suggestion is to invest time and increase knowledge about NBR 16690:2019.

Regarding the current of photovoltaic circuits and arrangements, as described in item 3.1.14, 15 and 16 of NBR 16690, the resulting total current is equal to the sum of all partial currents of each arrangement placed in parallel.

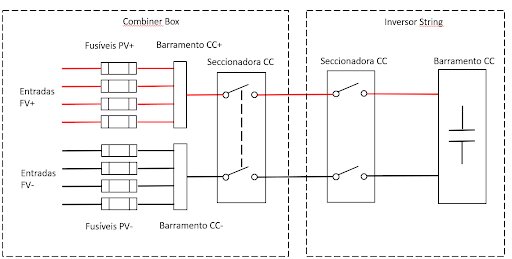

To give an example: a) if an arrangement is the result of the parallelism of 10 other subarrays, the total current will be the current of the sum of all arrangements. In a string box or array junction box or combiner box, this is better understood, since we have multiple inputs coming from photovoltaic arrays (modules placed in series), and these multiple arrays are placed in parallel on the combiner box bus. .

As also provided for in the standard and in order to protect the circuits of the arrays and their photovoltaic modules and interconnection conductors, whenever the total current of the array is greater than the reverse current supportable by the module, overcurrent protection must be used and this in accordance with described in item 5.3.9, “overcurrent protection on the direct current side can only be used using fuse devices with gPV type fuses, in accordance with IEC 60269-6, or circuit breakers, in accordance with ABNT NBR IEC 60947-2 or IEC 60898- two".

Also, and in order to make it clearer in item 5.3.10 of this, it is described that: “Protection against overcurrents must be provided for photovoltaic subarrays if more than two photovoltaic subarrays are connected to a single CPU”.

The calculation of these protection elements is also described in this standard, but after calculation we must check whether they comply with the manufacturers' maximum currents, in this case the maximum reverse current supportable by the photovoltaic modules.

In the opinion of some technicians, in order to protect the modules (photovoltaic panels), it is necessary to use protective fuses in direct current circuits or circuit breakers, but they forget that we are also protecting the conductors, connectors, installations and the modules, since for the current to reach the modules, it has to travel through all these elements.

We also have risks of fires and heating above the permissible level in conductors, and we also have methodology and standards to carry out these measurements and reduce or eliminate risks.

1) Example of a string box

Note that each of the 16 inputs, whether on the positive or negative side, has protection against overcurrent and gpV type fuses, thus resulting in protection against current reversal through the conductors and photovoltaic modules above a bearable limit, pre-determined by the manufacturers.

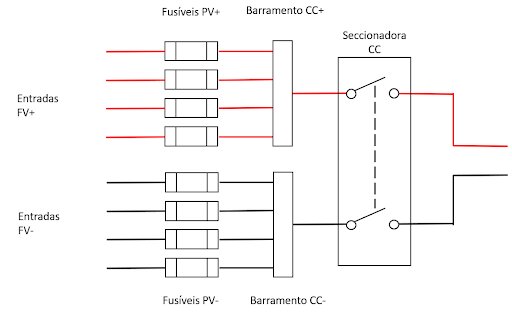

2) Example of protection in a photovoltaic inverter

Note that this inverter, with the direct current inputs coupled to it, has protection against overcurrent through fuses and/or circuit breakers, and thus, complying with NBR 16690 and protecting both the conductors and the modules in case of failure, thus protecting against excessive reverse circulation current.

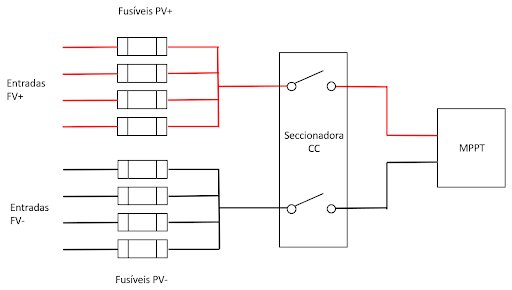

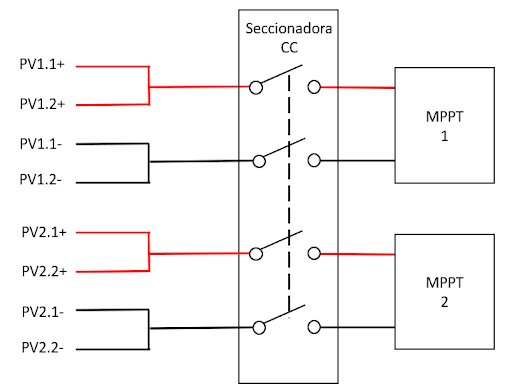

3) Types of inverters with 1 MPPT associated with string box

3) Types of inverters with 1 MPPT associated with string box

These inverters must always be coupled to a string box or combiner box and thus protect the subarrays, since the inverters do not have a protection device for each subarrangement and as all inputs are in parallel, in case of failure in a subarrangement the reverse circulating current could damage the conductors and photovoltaic modules, if these devices are not present.

1 MPPT inverter architecture – 60, 75, 125, 150, 160, 260…1000, 2000, 3400 kVA

4) MPPT multiple type inverters

Normally, and in most cases, these inverters, as they have two inputs (two subarrays) connected to an MPPT, do not require the use of overcurrent protection, as described above.

Note that they have up to two inputs, a disconnector with the potential to section and interrupt the maximum current and simultaneously the positive and negative poles and DPS on the DC side and the AC side.

However, as previously explained, the decision to use an associated string box or not is the responsibility of the designer, although in this case compliance with the standard would be redundant and, in some cases, may result in reduced reliability. of the system.

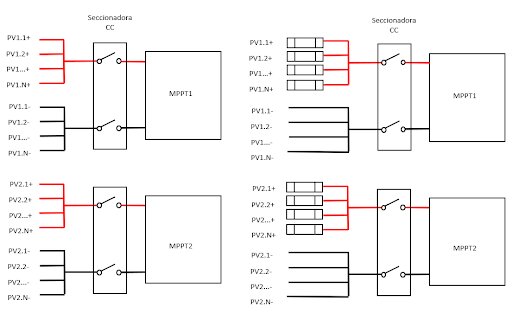

5) MPPT multiple inverter with multiple inputs in parallel

Some inverters have high current MPPTs and multiple inputs. The example below has 2 MPPTs of 100 A each, but each MPPT has up to 5 inputs (subarrays) in parallel.

After the disconnector, all subarrangements of each MPPT are placed in parallel in this way and in order to fully comply with NBR 16690 and not expose the installations, conductors and photovoltaic modules to risks, as described in items 5.3.9 and 5.3 .10, therefore require the inclusion of overcurrent protection, regardless of whether manufacturer A, B or C informs that the solution is fuse-free.

The final responsibility will always lie with the designer responsible for the design and definition of the equipment and its application.

Note that on the left side it follows exactly the construction form of this inverter with multiple MPPTs with multiple inputs. On the right side, the way it should be to comply with NBR16690:2019, since with multiple subarrangements in parallel it is necessary to include an undercurrent protection element.

If we have more than two inputs coming from PV modules, for example, the Canadian CS7N-660MB-AG module, admitting these with 10% of bifacial gains and, as informed by the manufacturer, the Imp is 18.98A, therefore, if we consider example five inputs at Imax=5xImod = 94.9A.

The manufacturer informs that the maximum reverse current supportable by the module is 35 A and not only for this reason, but also and most likely because we are using cables with a cross section of 6 mm², as we use an MC4 type terminal with a maximum current of 40 A.

If then one of the subarrangements has a fault and as we have them all in parallel, a circulating reverse current equal to 4xImod can then return, passing through the equipment disconnector which must then support this total current, through the conductor to that fault point and, from there, In this way, this point will receive 75.92 A.

The conductor, the disconnector, the MC4 type connector, as well as the module, must then withstand this current, however, it is very likely that none of the elements can withstand such current levels.

Therefore, and in order to preserve the integrity of the system and risks to the installations, NBR 16690:2019 indicates that overcurrent protection must be included in this equipment, since without the inclusion of an external element, these types of equipment are in non-compliance with current regulations, posing risks to facilities, users, investors and insurance companies.

One of several solutions would be to adopt at least fuses on the positive pole of this inverter or a circuit breaker in accordance with ABNT IEC 60947-2 in accordance with resolution NBR 16690.

Conclusion

For the evolution of the photovoltaic sector. continuous and applied investment in training and qualification of our professionals, increased supervision by competent bodies such as CREA, compliance with current technical standards, as well as the attention of our technical professionals in the preparation of projects aimed at ensuring the integrity of installations and users, as well as financial return to investors and always aimed at perfect interpretation by those responsible for implementations and installations.

Equipment can mitigate or reduce the risk of installations, but training, qualification and the correct application of competent technical and professional standards, these pillars form a safe and correct installation.

The time has come to professionalize our sector and create contingency measures so that installations are designed from the design phase in accordance with current standards, instead of creating mitigation measures for the real imminent risk to systems, which is often the lack of , absence or low qualification of our professionals.

As is the case in other sectors such as oil, gas, cement, mining, transportation, energy, among others, which invest heavily in professional qualifications, the engineering, installation and operation sector is recognized for having the best professionals, quality processes and procedures. and control, thus greatly reducing, and practically to zero, risks.

The solar sector must move in the same direction, with the adoption of control, inspection, training and qualification methods for professionals.

Our option has always been to meet technical requirements and never neglect any current technical standards. The application of the equipment in the project is always the responsibility of the responsible technician/engineer and it is therefore up to them to correctly interpret the current standards. The responsible engineer will always be the strongest link in the chain and, therefore, the person who will be responsible for his actions expressed in the form of a project.

It is also up to insurers to be more emphatic in complying with technical standards and, from the moment zero, express themselves regarding the needs and observances of established norms and standards, so that in the future, and in the event of an accident, they will not deny the insurance premium. , at the same time that we should demand that CREA inspect the installations through its representative and associate, the responsible engineer.

Brazil has the opportunity to enter into a position of recognition and sovereignty in the photovoltaic sector, however, we must increasingly pay attention to technical and safety standards and guarantee a safe return to investors and installations, as well as operational and of people.

3) Types of inverters with 1 MPPT associated with string box

3) Types of inverters with 1 MPPT associated with string box

One Response

I completely agree that there needs to be training of good technicians and engineers in the photovoltaic generation sector, whose expansion is irreversible. Rules were made to be followed and it is an extremely valuable document for managing legal disputes in the event of an accident involving insurers and clients. Working with DC requires different care than AC, for example, DC electric arcs are much more dangerous. Wires, cables, fuses, circuit breakers, protection elements, in general, are specific to DC. That old phrase; You can't turn off the sun and the modules are always generating. The project; the execution; conditioning; commissioning; assisted operation, etc., must be carried out and monitored with maximum rigor by qualified professionals. The dissemination of the culture of doing good. I'm one of those who don't believe in Murphy's law, because if it were true, cities would be an eternal bonfire. Engineer, professor, master in electrical engineering sciences – power system _ COPPE/UFRJ. Designer and consultant in energy efficiency and photovoltaic generation.