Article written by Diogo Pugas and Antônio Marcos Salgueiro

The definition of inverters in a solar plant is an important decision in project design. Some technical parameters will lead us to this decision.

In this article, we will discuss some characteristics of central and string inverters and the benefits of each one in several relevant aspects when choosing the best topology for each situation.

Inverter types

String

String inverters are designed for applications ranging from microgeneration to large solar plants. Today we find string inverters on the market from 0.5 kWac to 360 kWac.

Central

Central inverters are designed to large applications, from 1 MWac. Today we find central inverters on the market from 1000 kWac to 5500 kWac. Some of the main factors that must be taken into consideration when comparing the two inverter technologies are:

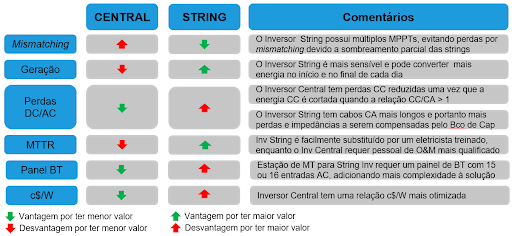

- Mismatching: is the difference in power between photovoltaic modules during manufacturing and/or due to external factors such as shading, dust, different inclinations or other defects on the surface of the modules;

- Generation: the maximum we can convert from the energy generated by the system, how much will need to be generated, at what times and what space is available for the plant;

- DC/AC electrical losses: losses occur in various parts of the photovoltaic system, both in direct current and alternating current; we must observe each part of the system individually in order to minimize them;

- MTTR: the mean time to repair, or in Portuguese, the average time to repair, what are the difficulties of each solution for resolving a system failure;

- Low Voltage Panel: Only necessary for the solution with string inverters, it makes the connection between the inverters and the step-up transformer of the converter station. Depending on the solution, whether outdoor or sheltered, its complexity may increase;

- R$/W: The value per watt of each solution is crucial for projects to become economically viable, both in terms of CAPEX (initial investment in the project) and OPEX (cost to keep it in operation).

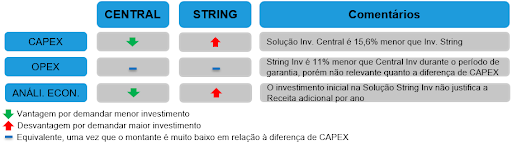

The figure below presents the main advantages and disadvantages of each of the technologies, central and string, when compared, in relation to the items mentioned:

To exemplify these comparisons we will now do a case study.

Case study

To begin the case study, we will analyze the characteristics of a fictitious 90 MWac project located in the North of Minas Gerais, with the following parameters:

- Total AC Power: 90 MWac;

- Total DC Power: 112.6 MWp;

- Mounting type: 1-axis trackers;

- PV module: Longi 530 Wp bifacial;

- Meteorological data source: Meteonorm 8.0.

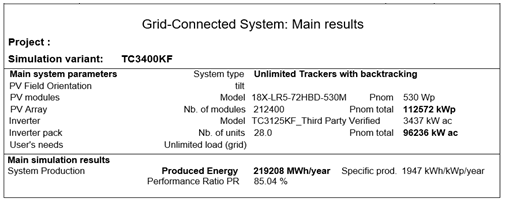

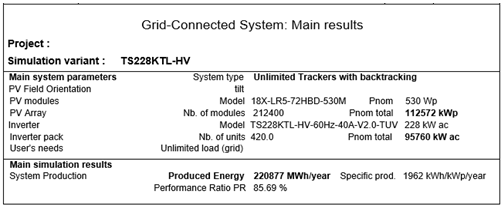

For the study we will use data from the string inverter TBEA TS228KTL-HV and the central inverter TBEA TC3125KF. Inserting the plant data presented above and the respective “.ond” files for each inverter into the PVSyst 7.2 application and we obtain the following results.

Central inverter

String Inverter

With the results above, we can see that the string inverter produced 1,669 MWh/year more energy than the central inverter, as previously predicted. The next step will be to collect the estimated costs relating to the solution with central and string type inverters for the project in question.

CAPEX

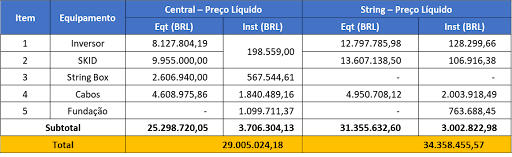

The table below describes the cost of equipment and installation currently available on the market:

Note 1: Equipment prices already include commissioning and assembly supervision costs;

Note 2: RS485 communication cables and string box infrastructure are included in the installation price of item 3.

As detailed in the table above, we can see that the solution with central inverters is more competitive than the solution with string inverters, reducing the CAPEX related to project implementation by 0.0476 R$/Wp or 15.6%.

OPEX

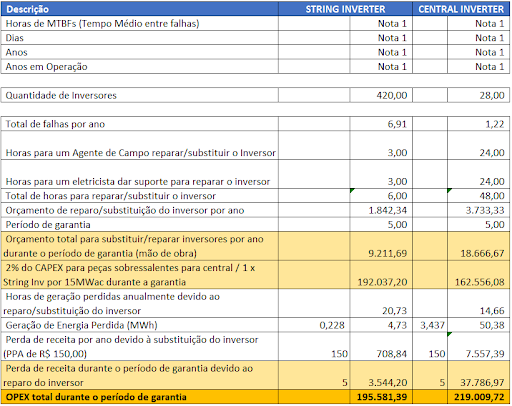

The table below describes the cost of maintenance and operation of the inverters for the 5-year warranty period, the standard warranty period for the inverters, based on the MTBF (mean time between failures) reports of the TC3125KF central type and TS228KTL- string inverters. HV from TBEA.

Below is a breakdown of the calculations:

Note 1: MTBF values are confidential and can be shared by signing an NDA (Non Disclosure Agreement) between TBEA and the client.

We can observe that during the warranty period of the string inverter, the calculated value of expenses for maintenance and operation of the equipment is R$ 23.4 thousand or 11.0% lower than that of the central inverter.

Although the string inverter has a failure rate greater than 5 times the failure rate of the central inverter per year, due to the greater number of inverters in operation, failures are resolved more quickly and at a lower cost, as we can see above.

Simplified economic analysis

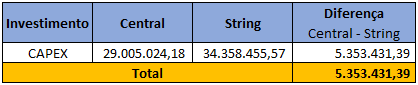

Carrying out a general economic analysis of the investment, comparing central and string inverter solutions, the difference in initial investment considered is as follows:

Making an economic projection of this value saved at the plant with the choice of central inverters and a return on investment rate of 6% per year over a period of 25 years, the typical useful life of a solar project, we have:

- VA = 5,353,431.36;

- I = 6.0%;

- n = 25 years.

Therefore, the future value referring to the result of these initial investment savings will be R$ 22.98 MM. However, as the string inverter generates more energy than the central inverter, we also analyze, in economic terms, the value of this additional energy generation.

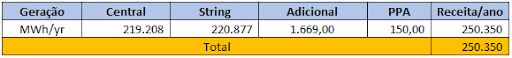

Considering a value of PPA (Power Purchase Agreement) of R$ 150.00, the incremental revenue with the string inverter solution would be R$ 250,350.00 per year, as illustrated in the table below:

Also considering a rate of return of 6% per year, for a period of 25 years, as done previously, the additional revenue provided by the string inverter would be R$ 13.74 MM. Therefore, with the same return rate of 6% per year on the CAPEX savings with the central solution, we saw that the energy gain provided by the string solution does not justify its initial investment.

Conclusion

As a final result of the case study, we can conclude that the central inverter presents itself as the best cost/benefit solution for this project, as illustrated below:

However, for each case a study is necessary because in general both solutions present advantages and disadvantages to the detriment of the particularities of the project and client profile.

For small distributed generation plants, for example, the string solution is best suited due to the availability and ease of replacing the product without the need for specialized technical staff. However, for centralized generation projects, with customers who will have more specialized O&M teams, the solution with central inverters presents itself as the best cost-benefit.

References

- Henry, R.; Tavares, P. What is the best topology for PHOTOVOLTAIC PLANTS. RBS Magazine, ed 46, pg 57;

- Schneider Electric. A Quantitative Comparison of Central Inverters and String Inverters in Utility-Scale Solar Systems in North America, Life is On, December 2016;

- VARGAS, JP; GOSS, B.; GOTTSCHALG, R. Large scale PV systems under non-uniform and fault conditions. Solar Energy, vol. 116, p. 303–313, 2015;

- Araújo, E. The problem of mismatch in photovoltaic installations. Canal Solar, June 4, 2020. Available at: https://canalsolar.com.br/mismatch-nas-instalacoes-fotovoltaicas/. Accessed July 21, 2022.