Unlike most string inverters, Microinverters work with a well-defined number of photovoltaic modules, which cannot be adjusted by photovoltaic system designer.

We can find microinverters that work with one, two, four or up to eight photovoltaic modules. It is possible to question the extent to which many of these devices still respect the philosophy of the “micro” inverter, that is, the small inverter, with reduced power and dimensions.

In any case, all equipment called microinverters by their manufacturers still preserve these main characteristics, which differentiate them from traditional (string) inverters: they operate with a smaller number of modules, which does not require the formation of strings and series module connections, has reduced physical dimensions and are installed close to the photovoltaic modules.

We can also mention other characteristics of microinverters or the systems that use them, which are consequences of the facts mentioned in the previous paragraph: microinverters avoid the use of direct current cabling and stringboxes in facilities, operate at reduced voltage levels and eliminate the risk of electrical arcing, which are the main cause of fires in photovoltaic systems.

Many professionals point to microinverters as the safest option for building photovoltaic systems, as they completely eliminate the risks of electric shocks and fire, being very suitable for operation in places with risk classification (such as gas stations, for example).

The advantages of using microinverters over traditional inverters are debatable and we will not cover them in detail in this article.

Some of the advantages pointed out by the designers, in addition to those already mentioned above, are the elimination of problems with partial shadows in photovoltaic systems and the reduction of energy loss through “mismatch” of power of the photovoltaic array modules.

The disadvantages that accompany microinverters are the additional cost they add to photovoltaic systems, the increase in the number of system components – which makes this equipment unsuitable for large solar plants –, the difficulty in replacing them in the event of a defect (as they are installed under the photovoltaic modules) and the aggressive operating conditions to which they are subject, as they are installed on roofs and are exposed to high temperatures (which inevitably leads to a reduction in useful life, unless the equipment is very well designed and tested before use. be introduced onto the market).

Microinverters for 1 photovoltaic module

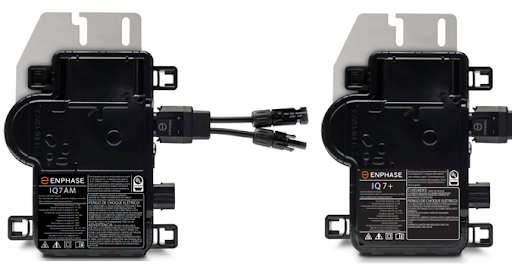

You Enphase IQ7AM and IQ7+ microinverters, shown in Figure 1, are examples of equipment that preserve the original philosophy of the microinverter, since it was introduced on the international market in 2006.

Essentially, the idea of the microinverter arose to enable the direct connection of the photovoltaic module to the alternating current network, without the need for direct current cabling, giving the photovoltaic system a characteristic “plug and play” (“plug and play”) – that is, quick and easy to install.

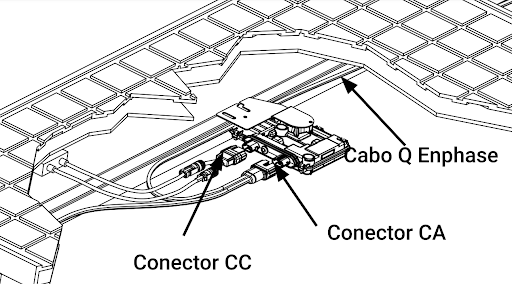

Figure 2 illustrates how Enphase models are installed individually under PV modules. The equipment has only two electrical connections: one for the photovoltaic module (CC) and one for the connection to the trunk cable (called “Q cable” by this manufacturer), the latter responsible for connecting to the alternating current (AC) electrical network.

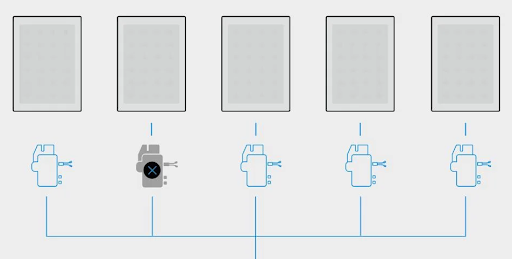

What differs the IQ7AM and IQ7+ models is the maximum operating power. Both are intended for connecting just one photovoltaic module, as shown in Figure 3.

Microinverters for 2 photovoltaic modules

What determines the number of microinverter modules is the number of MPPT inputs, the number of modules that can be connected in series at each input and the nominal power of the equipment.

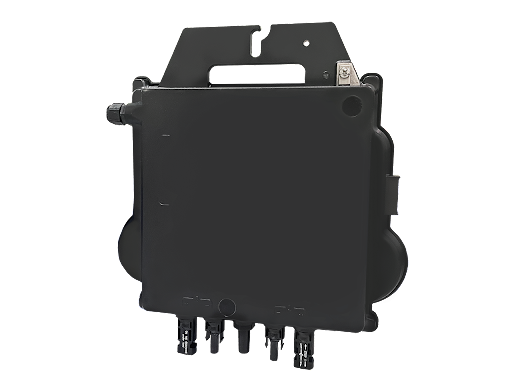

Normally all these characteristics are interconnected. For example, the Deye model SUN600G2-US-220, illustrated in Figure 4, has two MPPT inputs and a nominal power of 600 W, which allows the connection of up to 2 photovoltaic modules (one at each input).

In this case, it would not be possible to connect two modules per input, as occurs in some models from other manufacturers, as the equipment's power would be exceeded – in addition to the fact that the inputs are not prepared to receive the electrical voltage of two modules in series.

In addition to the example shown here, the same manufacturer (Deye) has higher power models, with the capacity to operate with up to 4 photovoltaic modules.

Microinverter models with power in the 2000 W range are intended for use with up to 4 photovoltaic modules.

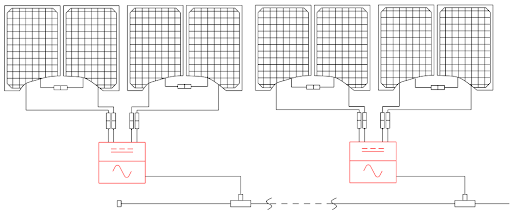

An example of this type of equipment is the model DS3D by APSystems (Figure 5), distributed in Brazil by Ecori, which has two independent MPPT inputs and can receive up to two modules per input – in this case, two modules must be connected in series at each input, as illustrated in Figure 6 .

Other examples of microinverters for 4 photovoltaic modules are the models Hoymiles HMS-1800-4T and HMS-2000-4T, which have 4 independent MPPT inputs. According to the manufacturer's data sheet, the models are recommended for modules in the range of 360 W to 565 W (HMS-1800-4T) and 400 W to 625 W (HMS-2000-4T).

Microinverters for 6 to 8 photovoltaic modules

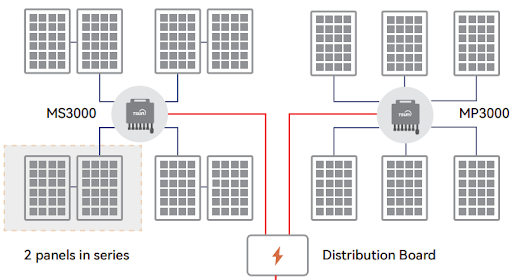

The models TSUN TSOL-MP3000 and TSOL-MS3000, illustrated in Figure 8, can connect to up to 6 or 8 photovoltaic modules, respectively.

The model TSOL-MP3000 It has 6 independent MPPT inputs and can receive one module per input.

On the other hand, the model TSOL-MS3000 It has 4 MPPT inputs and can receive up to 8 photovoltaic modules, with two modules connected in series at each input, as shown in Figure 9.

The opinions and information expressed are the sole responsibility of the author and do not necessarily represent the official position of Canal Solar.

3 Responses

I have a lot of gratitude for the CANAL SOLAR team, as they always have something new for our society as a whole, continue on this journey, these are our Brazilian people (BRAZIL) thank you

Clearly the author does not know the subject because he stuck to random information that does not portray reality. A generator with a string inverter will NEVER be more interesting than an MLPE. There are no more elements in the system, it allows individual control per module and even the lay customer can understand when and if something does not happen in the ideal way. They are no longer expensive (string inverters require string boxes) and what matters is not the CAPEX cost but the calculation over the entire useful life.

Presentation of very good quality and easy to understand for anyone, whether layman or specialist. Canal Solar is to be congratulated on the article.