Under the bias of reducing the price of solar inverters and meeting the latest versions of bifacial photovoltaic panels with higher power, these exceeding more than 650 Wp and MPPT currents above 15 A, several manufacturers have been using their inverters with DC protection switches in different MPPT settings.

Many industry experts discussed the protection capabilities of DC-side switches and their compliance with technical standards.

The main controversy focuses on system design where “the number of strings connected in a single MPPT exceeds 2 strings”.

Is only the protection provided by DC isolation switches safe for the system? Or is there a need to add protection devices, such as fuses or circuit breakers, when the equipment configuration allows the connection of 3 or more inputs to the same MPPT?

Currently, many string inverters have used the concentration of more than 2 strings in the same MPPT due to the increase in the power of photovoltaic panels. But what is their real protection capacity?

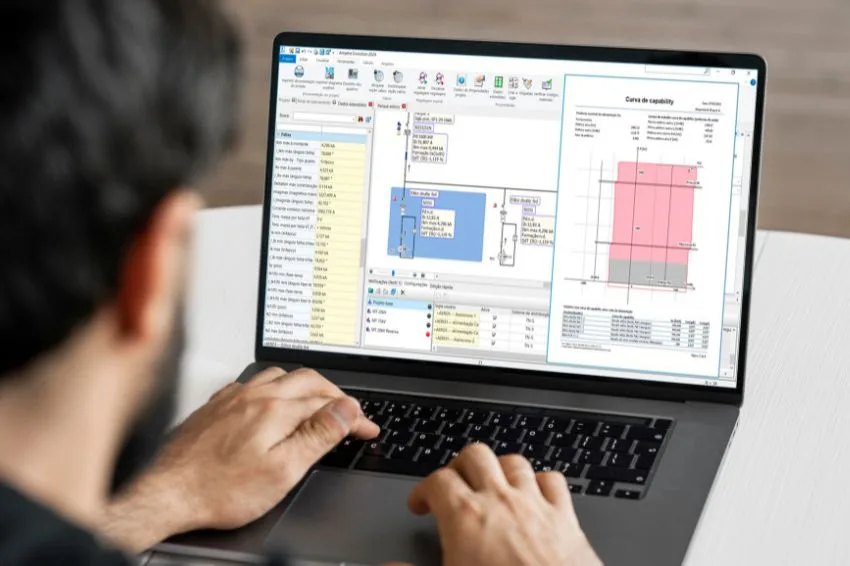

The R&D team of manufacturer TBEA carried out reverse connection and reverse current tests in its laboratory and photovoltaic plants to verify the safety performance of DC switches currently used on the market, in order to demonstrate how this type of configuration interacts with the rest of the system in a failure situation.

1) Verification and testing in reverse connection scenario

During the construction, installation, operation and maintenance of the inverter, incorrect connections often occur, which produce effects such as short circuits, polarity inversion, among others, which poses safety risks to both the system and operators.

Therefore, the system protection capacity conferred by the equipment functions is extremely critical.

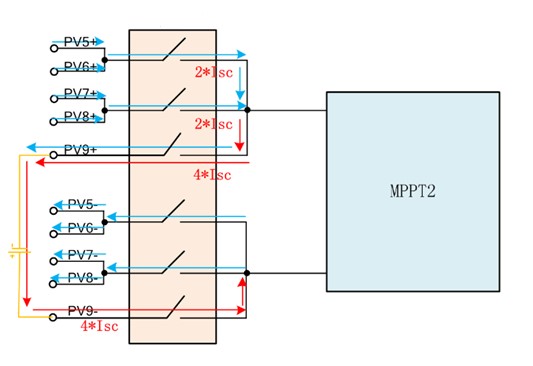

In tests carried out by TBEA, each MPPT of the selected equipment was connected with 5 strings of photovoltaic modules, with a single string current of approximately 20 A.

A string of selected equipment was tested using a reverse connection of the positive and negative poles. After incorrect connection, the reverse connection string adds up with the other 4 strings.

In the loop, currents from the other 4 strings “feed” the incorrectly connected string, forming a return current of around 70 A.

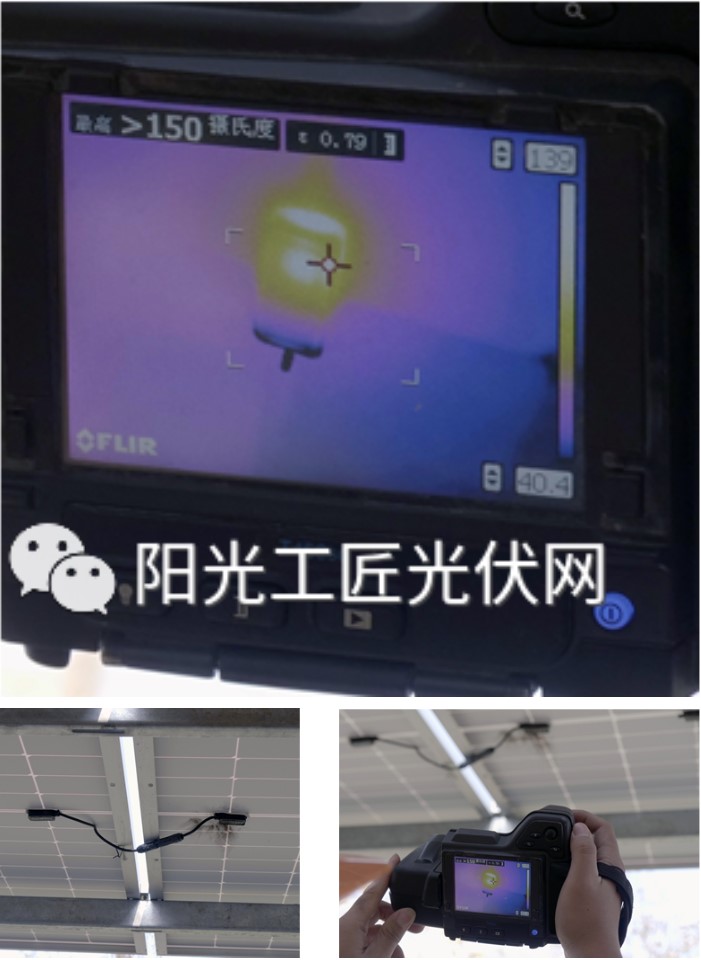

After the first test, the DC protection switch operated, but the trip only occurred after 240 ms, a time considerably longer than the 15 ms announced by the manufacturer.

After the second test, the DC protection switch failed to operate and the existing return current caused a sudden increase in the temperature of the corresponding string components. The diode temperature of one of the components exceeded 150℃, effectively burning out.

2) Verification and testing in operational scenario

Additionally, due to the large area occupied by photovoltaic modules in plants, various factors, such as uneven lighting, shading and aging of photovoltaic modules, frequently occur during the operation stages. Inconsistent power generation from each module can easily lead to a voltage difference across the string, which can result in reverse current.

If this reverse current cannot be effectively protected, there will be a significant increase in system safety risks.

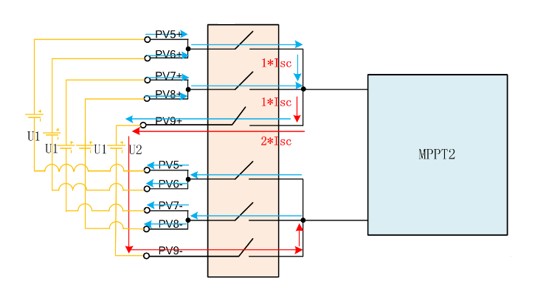

To check what the behavior of the DC switch would be when connected to an MPPT with a greater number of strings at the input, in relation to the reverse current due to different voltages in the arrangement, one of the strings under test was subjected to a lower voltage in relation to the other 4 strings. connected to the MPPT.

This caused a reverse current that reached 40 A. Under these circumstances, 3 rounds of tests were conducted.

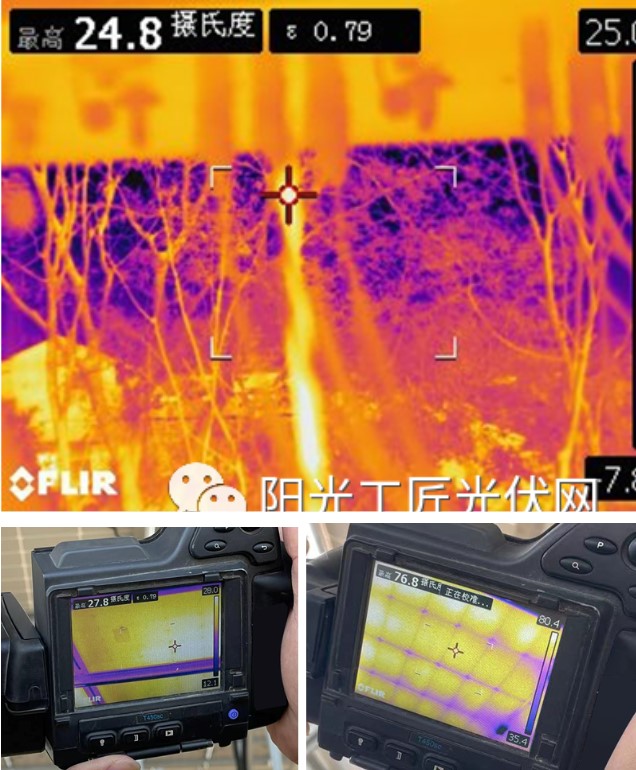

After the first 2 tests, the DC switch operated its protection, however, again, the trigger was carried out after 250 ms, against the 15 ms indicated by the manufacturer.

And in the case of the 3rd test, the CC switch failed, not fulfilling its protective role. The temperature of the corresponding components and the circuit increased sharply, with the temperature of the photovoltaic panels in the lowest voltage circuit reaching 76.8 °C in one minute.

In a scenario where disconnection does not occur in a suitable time, the temperature will continue to rise, creating a potential fire source in the installation, in addition to other undesirable effects, such as loss of generation and a reduction in the useful life of components.

The tests carried out and the results described above indicate that when 1 MPPT channel is connected to more than 2 string inputs, the DC switches used today may not fulfill their protection function effectively, facilitating the occurrence of damage or fires and accidents. .

And even if the DC switch supports the conditions and fulfills its role, the rest of the DC system may be exposed to anomalous conditions than those foreseen in the project, impacting, at the very least, the useful life of the components that make up the system.

Conclusions

- In a system that uses string inverters where the number of input strings per MPPT is high, it is necessary to consider the application of overcurrent protection devices, such as fuses or circuit breakers, to guarantee the safety of the installation and its operators, a necessity. normally not foreseen in the project and in the LCOE calculated to define the solution;

- Nowadays, we have inverters available on the market up to 250 kW that provide up to 9 MPPTs of 40 A each, enabling the direct connection of two strings to each MPPT, thus avoiding the problems presented in this study for connections when using high voltage boards. power with MPPT currents between 15 A and 20A;

- For boards with MPPT current greater than 20 A, we have inverters available on the market with 12 to 14 MPPTs of 30 A, thus allowing the connection of a string per MPPT with an overload factor suitable for most applications;

- Using inverter solutions with a greater number of MPPTs will result in greater energy production, with a view to reducing the effect of mismatch due to shading or heavy dirt on part of the plant's photovoltaic panels. Using a maximum of 2 strings per MPPT in string inverters is the best technical solution.

8 Responses

Good afternoon, can I connect 1 string to an Mppt with input of 2 strings?

Hello William,

Yes, you can use only one of the inputs, the recommendation is that you check the parameters indicated in the datasheet of both the Inverter and the photovoltaic module to obtain the best performance, and to ensure that the voltage and current limits are respected.

In an Inverter scenario with MPPT for 2 STRINGs, but due to the maximum MPPT current of 32A, using a photovoltaic module with Short Circuit Current (Isc) 18.69A, can I leave one STRING empty? If I use both STRINGS the current (2*18.69A) exceeds the MPPT limit.

Yes, it must be done this way so that the current limits are respected, remember to check the maximum voltage on your string too, to avoid any types of problems in sizing and operation.

I have a 15k inverter with 2 mppt and 3 strings for each mppt, I can only connect 1 string for each mppt.

Hello Gabriel,

When the inverter has more than two inputs per MPPT, there must be a protection device per input, so I recommend that you check whether the module respects the protection characteristics of each of the inputs of this inverter, if so, there should be no problems using it in this way.

How does an MPPT work with two strings? Is each string monitored individually or does MPPT treat the two strings as if they were one?

Good afternoon, Wilson, how are you? is treated as if it were a single string