If you work in the photovoltaic industry, at some point you must have heard about the PVEL (PV Evolution Labs), one of the leading independent laboratories of the global market and now part of the Kiwa Group, European industry inspection institution. But do you know what yours is? real importance for the segment?

PVEL has a scorecard module reliability, which is an assessment of the quality of the panels that are available in the sector. This means that it classifies manufacturers over a period of 18 months, based on product qualification tests.

This program encompasses several tests, including CT (Thermal Cycle), which evaluates the ability of a photovoltaic module to withstand temperature changes – which makes it particularly significant in regions with extreme variations, where TC performance is essential. as is the case in Latin America.

The PVEL Qualification Program is designed to subsidize buyers, investors and owners of photovoltaic generators. In total, the laboratory works with more than 400 downstream partners, representing more than 30 GW of annual purchasing power in the world's main solar energy markets.

Classification of companies operating in Brazil

Recently, the Aurora Mono Perc modules from the AE Solar, a German Tier 1 panel manufacturer, for example, have passed the Thermal Cycle, in which the equipment, with a power of 550 Wp, demonstrated exceptional resistance to temperature fluctuations.

The 182mm mono PERC modules, manufactured exclusively to 4.0 production standards, have passed three PVEL tests. The line is currently available in Brazil.

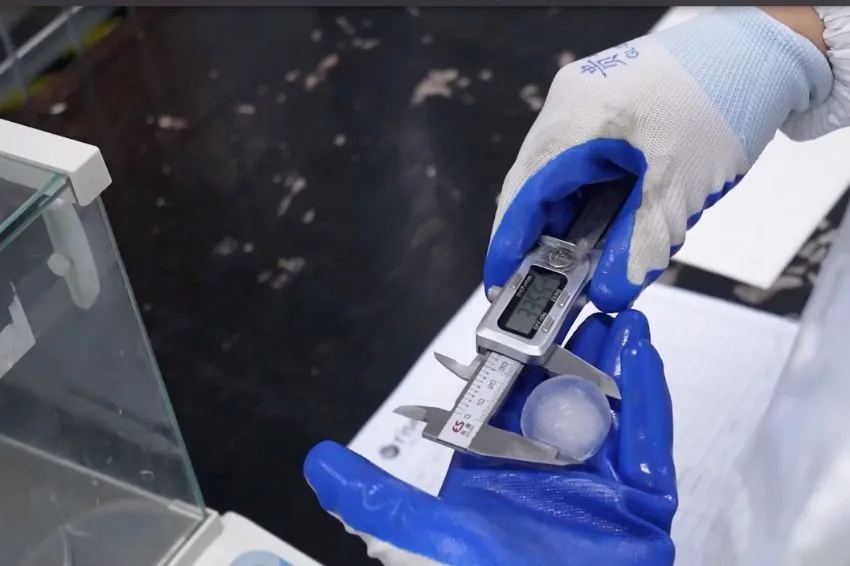

In the test of MSS (Mechanical Stress Sequence), which assesses the panel's vulnerability to cracking and whether cell damage can lead to energy loss, AE Solar's products also achieved excellent results.

“AE Solar’s Aurora mono PERC modules have proven their resilience even in adverse weather conditions, such as heavy snow and strong winds, which makes them the ideal choice for projects in regions with extreme weather events”, highlighted the PVEL result.

Finally, such equipment also passed the LID (Light Induced Degradation) and LeTID (Light and High Temperature Induced Degradation). These cell-based phenomena, triggered by light exposure, are crucial factors in energy yield models.

AE Solar's panels not only stabilize quickly in the field, they also minimize LeTID, making them particularly suitable for hot climates where other modules may have difficulty maintaining efficiency.

According to Ramon Nuche, director of AE Solar for Latin America, the Aurora Mono Perc line represents the pinnacle of photovoltaic technology, “offering unparalleled efficiency, durability and reliability”.

“With the excellent PVEL rating, we will continue to set new standards in the solar industry by providing our customers with the best performing solar modules available,” he concluded.

Other PVEL tests

For its traditional classification of the photovoltaic sector, PVEL still works with the following types of tests:

- Damp Heat (humidity and heat test): simulates module degradation in more aggressive conditions, high temperatures and high humidity;

- Potential Induced Degradation (induced degradation potential): simulates the voltage and temperature conditions to which the panels are exposed. Therefore, the electrical degradation induced due to high voltage is analyzed;

- PAN Performance (Pan performance): determines whether the modules’ performance is aligned with the information in the PAN File;

- Backsheet Durability Sequence (backsheet durability sequence): identifies possible defects in the backsheet, which cause moisture ingress and can affect module performance;

- Hail Stress Sequence (hail stress sequence): simulates field conditions to evaluate the panel's durability and resistance to the impact of natural hail.