Lithium batteries with liquid electrolyte are commercially available in cells, blocks (packs) and banks.

Cells are the basic units, which typically have storage capacities of the order of 1 to 5 Ah, with a nominal output voltage of 3.7 V.

For practical applications these cells need to be organized into blocks or packs, where they are connected in series.

The blocks or packs of batteries must be associated with electronic BMS modules (battery management system) for safe operation.

This is extremely necessary for lithium batteries, as the cells are not identical and can work under different load conditions, with different electrical voltages at their terminals.

Lithium-ion cells are extremely delicate. Each cell within a block is unique and must be carefully balanced and monitored to prevent overcharging and overheating.

Lithium cells have their voltage suddenly increased when they are overcharged. If an overload occurs in just one cell of a pack, this cell can reach dangerous voltages before the total block voltage reaches the level corresponding to maximum charge (which would be detected by a simpler charge controller).

Therefore, controlling and monitoring the total voltage of a block of cells is not sufficient for lithium batteries, unlike what happens with lead acid batteries, for example, with which no special care is required during the process. charging from a bank.

The manufacturers of packs and battery banks (which can bring together one or more packs) classify and carefully select the cells according to their capacity, internal resistance and date of manufacture, seeking maximum uniformity of the cells when grouped. Even so, BMS circuits are required in commercial battery blocks and banks.

The most important function of a BMS system is to ensure that cells remain within safe operating limits and to take action as soon as any of the individual cells begin to go out of bounds. The action taken depends on the complexity of the BMS.

Normally the BMS will disconnect the circuit to prevent the battery from overcharging (if the voltage is too high) or over-discharging (if the voltage is too low).

It will also check whether the cells of the pack have the same voltage, actively acting on some cells so that their voltage is equalized with the others. This individual cell control prevents overvoltage and fire.

Some BMS systems can also monitor temperature and disconnect the circuit if the cells reach dangerous conditions.

In summary, we can list these main functions for a BMS system (battery management system):

- Monitor the voltage of the battery bank and individual cells, protecting the cells and the assembly against overvoltage;

- Equalize the voltage of each cell, actively acting on cells that present an imbalance;

- Monitor cell temperature and control the cooling system, if applicable;

- Monitor the charging and discharging current of the battery bank, protecting against overcurrent;

- Estimate the state of charge (SOC = state of charge) of batteries;

- Monitor the battery discharge depth (DOD = depth of discharge), protecting against excessive discharge;

- Monitor the number of charge and discharge cycles and indicate the end of battery life.

The BMS system of a pack of batteries can be of two types: centralized or decentralized. A centralized system consists of a single electronic board that has connection terminals for the bank's individual cells.

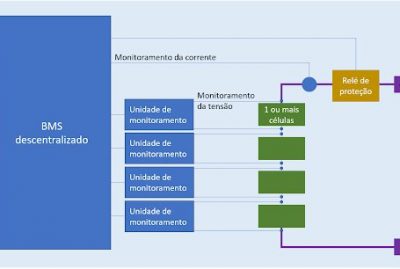

A decentralized system employs electronic boards for a specific number of cells, which communicate with a central control board.

The strategy employed, centralized or decentralized, depends on design decisions. Typically the centralized BMS is for low voltage battery banks, typically up to 100 V.

Decentralized BMS systems apply to higher voltage banks, reaching 1000 V or more, in which a smaller number of cells are monitored by a monitoring unit, while the central control board communicates with several units.

One Response

Very good explanation about lithium batteries, congratulations

we manufacture transformers and supply to some companies that make solar energy installations