Centralized or decentralized? What is the best layout for a large-scale photovoltaic plant?

Whatever the project, what matters is the reliability of the products and the security that the plant delivers the desired results.

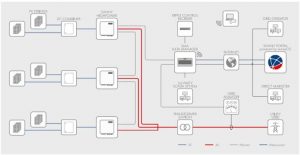

The main factors that influence the selection of a centralized or decentralized system layout are described in detail in the following sections.

Every feature and every redundant component needs to be evaluated before being added to a product.

This is where a centralized system layout has the advantage over a decentralized system layout using traditional string inverters.

More MPPTs or more failures?

A widespread myth in the market today is that it is better to use more MPPTs. The fact is that it is extremely difficult to attribute losses to MPPTs on projects. The theory behind this is pretty straightforward.

Irradiation affects the current and temperature affects the voltage of photovoltaic modules. This means that in a typical plant, the voltage of one section cannot vary much compared to other sections, since a temperature variation of more than a few degrees is impossible.

All other factors such as module mismatch, shading, clouds, etc. are random in nature. The mathematics of random behavior clearly indicates that when switching from a module to a string, most voltage deviations are eliminated, simply because the voltages are summed in a photovoltaic string.

This becomes even less prominent as you go from 600V to 1500V and from 1000V to 1500V, simply because the number of modules in the series is greater.

This means that if you have 0.x% gains with power electronics at module level (1 MPPT per module) and move to string MPPT level (30 modules in series per MPPT), most of the gains will be eliminated . When you go from the string level to the center level, there is effectively no gain left.

Another point to remember is that voltage and current measurement sensors are not designed for highly accurate measurements. This means that typical deviations with the spine measurement can also mislead the MPP tracking behavior.

Finally, it is important to note that using more MPPTs comes at a high cost. First, the losses from having more MPPTs can reach 0.5% in most cases.

Secondly, extra components (such as sensors) inside the inverter would again reduce the reliability of the entire inverter. Remember that each extra component should last 20 years.

A single failure in an MPPT-related component would mean complete failure of the inverter. Several studies, including internal SMA studies, support the above findings. Therefore, a general principle is: the fewer the number of MPPTs, the better for the customer, not the other way around.

Avoid cabling losses

A typical decentralized string inverter design works best with 600V technology, which was the norm about 10 years ago.

Let's take a hypothetical inverter, for example, with 600 VDC and 600 VDC. In this case, the DC components between the inverter and the PV modules do not matter. But as the new DC module technology has evolved from 600 VDC to 1500 VDC, today's scenario is much more favorable on the DC side because the DC current is typically reduced by 2.5 times.

This means that it is much more efficient to transfer power on the DC side than on the AC side. Additional disadvantages include the need for four AC cords instead of two, as well as the difficult installation of AC cords.

The centralized layout also allows working at the low voltage (LV) level (690 V) on the AC side due to the short cabling between the inverter and transformer. Staying in BT has many practical and valuable advantages.

The commercial attractiveness (such as price, delivery time, supplier availability) of all components between the inverter and the MV connection is much better compared to the same components certified for voltages above 690 VAC. In a high DC overhead scenario, the benefits of centralized architecture are enormous. Consider an overload case of 150% DC (1.5 MWp of PV modules and 1 MW inverter).

A typical string inverter would first limit the power (clipping) and then transmit the available DC power long distance to the transformer (approximately 1% of loss). This means that 1.5 MW would be capped at 1 MW and when it reaches the medium voltage transformer there would be 0.99 MW left, whereas a centralized architecture will transmit first and then cap.

This results in a loss of 1% on the DC side before it reaches the inverter during transmission. When it reaches the medium voltage transformer, you still have 1MW.

This additional gain of 1% occurs during periods of increased solar radiation. When the effect is observed in terms of kWh, significant gains can result for the plant owner. It is also important to remember here that during clipping, the MPPT functionality of the inverter is disabled and therefore unusable!

Communication cabling is another factor that adds cost to a decentralized plant layout. Ethernet cabling must be installed throughout the plant. The cost of cabling, field installation difficulties, and potential maintenance issues with communication make a centralized layout financially attractive.

Powerline communication for utility applications has many disadvantages. Even for small amount of data, the speed is prohibitively slow and cannot be considered for time-critical application such as network management functionality.

Advantage of OptiCool

In every inverter, cooling technology is definitely one of the most important aspects after power electronics. SMA has mastered this with a simple and reliable design technology just for photovoltaic applications.

We have seen many different approaches that have been tried and failed. However, nothing beats OptiCool's simple speed-controlled fan design. The key to the longevity of a PV inverter is to have the lowest thermal cycle possible. It is not the absolute temperature, but rather the fluctuations that matter.

SMA has done several studies on this topic and in some cases has even observed that heating the inverter at night (such as in desert climates) increases component life. Photovoltaic inverters are extremely compact. Even at the highest efficiency, massive heat dissipation is required.

For example, the Sunny Highpower PEAK3 has an efficiency of 99.1%. But even when it's at full power, it should dissipate about 1.5 kW of power. This is comparable to twice the energy used by a household microwave or electric heater. In other words, if we collect the spare heat from a Sunny Highpower PEAK3 inverter, it can power a typical home.

This amount of energy must be dissipated by the Sunny Highpower PEAK3 in a volume smaller than that of a typical refrigerator. This amount of heat dissipation cannot depend on fanless cooling.

It is known that in typical photovoltaic applications natural cooling due to gusts of wind or rain can easily reduce the useful life of components significantly. The inverter simply won't last 20 years.

OptiCoolTM maintains uniform temperatures throughout the day as the fans are speed-controlled. Thermal cycling and heat dissipation are minimized to greatly extend the life of the inverter.

Inverter maintenance

This point clearly favors the modular central inverter design in the sense that there is almost no dependence on on-site support from inverter manufacturers. This could be a real deciding factor for plant operators, but it is more of a mindset than a financial consideration.

Purely from a failure and power loss perspective, central inverters are still the best option despite their dependence on on-site support. In the end, it is up to plant owners to decide how best to deal with such a scenario.

Conclusion

A centralized system layout is clearly preferred when it comes to large-scale ground-mounted PV projects. Outside of a very restricted range of application, the concept of a decentralized system does not make sense from a financial and cost-benefit point of view.

The real question for plant owners is whether to choose a single large central inverter or multiple smaller inverters, and the decision is heavily driven by the concept of appropriate service for a given project and the dynamics surrounding the project.

The design of the Sunny Highpower PEAK3 solution is perfect to provide benefits from both worlds. For photovoltaic system designers, it is simply a Sunny Central UP divided into 25 to 30 “manageable parts”. It is much closer to the centralized approach preferred by most photovoltaic system designers.

The opinions and information presented are those of the author and do not necessarily reflect the opinion of Canal Solar.