Distributed generation photovoltaic systems have an increasingly present role in today's society. The popularization of these generation systems has raised several concerns from their users and entities in relation to points such as safety of these systems in relation to fire it's yours impact on connection to the electrical grid, in Brazil and around the world.

An important factor to consider when it comes to security is the physical and economic security of system installers, who expose themselves to risks, such as working with electricity and at heights.

The correct training of these professionals must be a priority to address the issues involved in safety that will be mentioned. By choosing high-quality equipment and carrying out appropriate installation, the economic risks of the company responsible for installing the photovoltaic system can be greatly reduced.

In contrast, the installation and design are the most critical points to ensure the safety and useful life of the system. However, high-quality equipment is not enough to guarantee the total safety of installations if the workforce is not trained.

In this article, the main causes of problems and the solutions that can be incorporated to increase the safety of photovoltaic systems.

When addressing the issue of safety, both material and personal, in photovoltaic systems, attention must be paid to the use of electricity and the structural risk that the system load poses to the location where it was installed.

Fire risks

Regarding fire risk, UK statistics in 2017 show that out of approximately 1 million existing photovoltaic systems, there were only 58 recorded fire incidents [1].

In Germany, a similar proportion of incidents were recorded. Of the 54 GW installed to date, only around 0.006% were affected by fires [2]. Photovoltaic systems are safe by nature, when installed correctly and using high quality equipment, which guarantees the safety of the plant.

Causes of fires

When analyzing the causes of fires, in the Netherlands around 70% of recorded fire cases came from electric arcs on the direct current (DC) side of the installations [3]. In these cases, poor electrical connections, poorly installed connectors It is cross connections were listed as the main causes [4 and 5].

Connections

Among these causes, we can mention the lack of crimping correct connectors and cross connections. The crimping process must be carried out according to a correct procedure and with specific tools.

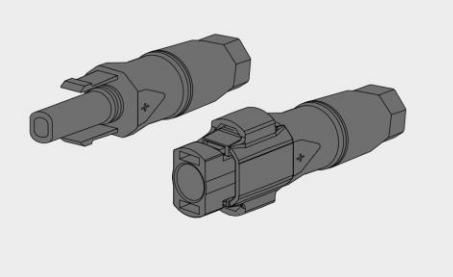

Cross-connection is the name given to a connection using two non-compatible connectors that, due to constructive similarity, are mechanically coupled. However, although they can be mechanically coupled, these connectors, as they are from different manufacturers, do not enable the correct electrical connection between them.

In two connectors where there is no appropriate connection, an oxide layer can form between the contact poles, causing transition resistance.

This resistance can lead to the development of hot spots within the connector, which can result in an ignition point for a fire through an electrical arc internal to the connector. Likewise, it is possible to state that the same problem occurs with connectors installed incorrectly [3, 4 and 5].

Electric arc

As seen previously, the electric arc is the biggest villain in electrical installations. When talking about direct current, the arc is even more critical, due to the fact that it occurs even at lower voltages, compared to the voltages of alternating current circuits. The direct current arc is difficult to extinguish. In addition to favoring the start of fires, this type of arc makes it difficult to fight the fire once it starts [5].

Lean systems bring greater security

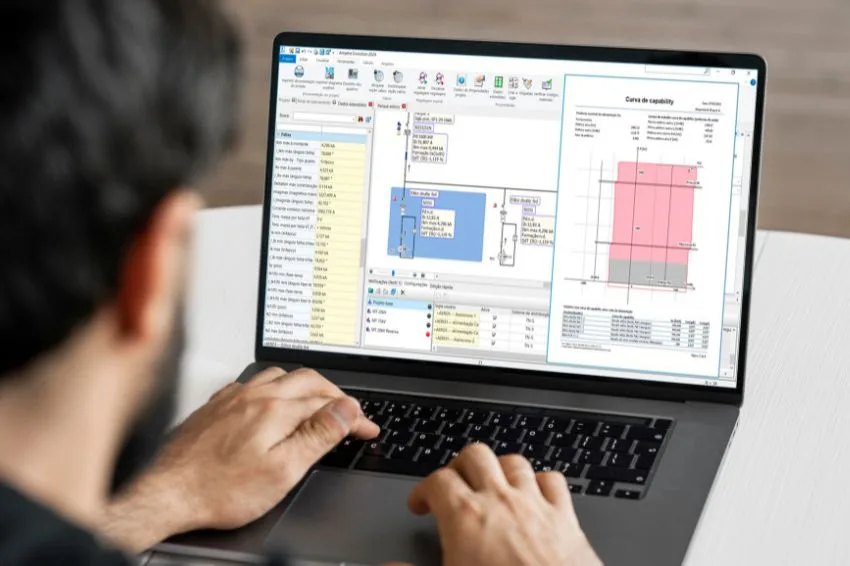

The safety of photovoltaic systems has continually evolved as technology advances and systems become more popular. For example, residual current monitoring devices, insulation resistance measurement, protection against reverse polarity and other functions have been integrated into inverter technology, in order to guarantee the safety and stability of the system's operation.

SMA ArcFix

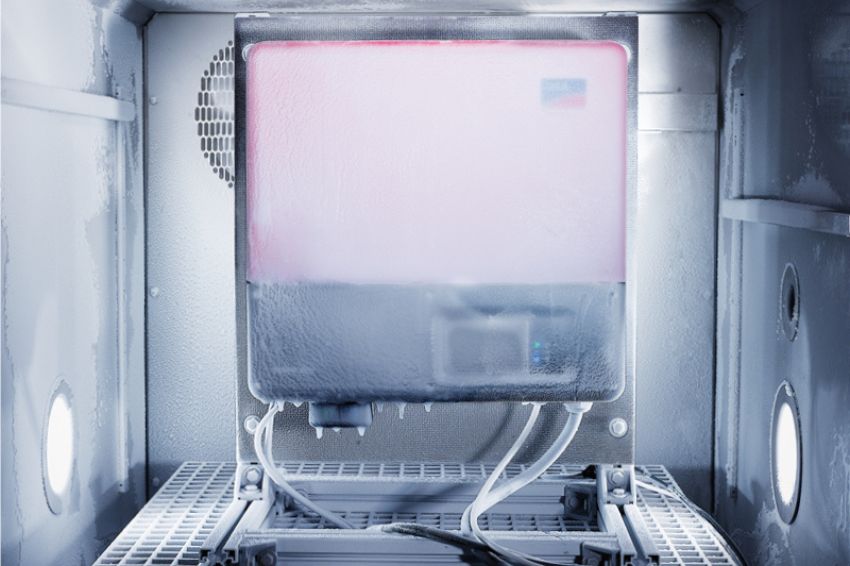

In addition to these technologies, SMA has developed the SMA ArcFix, one arc flash detection and interruption system (AFCI), making the system safer and more reliable in an intelligent way, with minimal addition of electronic components.

The SMA ArcFix system efficiently detects potential electrical arcs in photovoltaic arrays and interrupts the electrical circuit before the point where the arc would form heats up and, consequently, leads to a fire. SMA is a pioneer in the application of the AFCI system in the United States of America and has been developing and improving this solution for more than a decade.

SMA solution for connectors

Regarding electrical connections, which were presented as the main cause of fire, SMA has been solving the problem in a simple way for years. The connection between the photovoltaic modules and the inverter is made using the connector SUNCLIX.

SUNCLIX is an exclusively compatible connector, which eliminates the possibility of cross-connection, as it does not fit with the most common connectors on the market.

The SUNCLIX connector does not require an exclusive tool for assembly, making the photovoltaic system more reliable, due to the fact that assembly is much easier, minimizing errors. Electrical connections become simpler and safer when using SMA inverters.

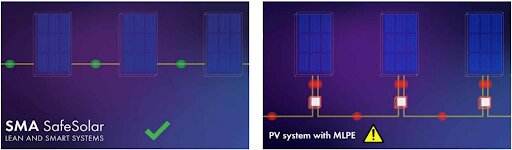

More secure installation with fewer devices

As seen previously, faults in electrical connections are the main cause of electrical arcing, which in turn is the main cause of fire in photovoltaic systems [3 and 5]. In a conventional string system, there is only one connection between two photovoltaic modules, as shown in the figure above.

When we use systems MLPE (power optimizers or inverters), the number of connections increases drastically, as an additional device is placed between the modules, increasing the risk of electrical arcing in this installation.

In addition to the additional connections, it is necessary to ensure that the connections between modules and electronic optimizers are of the same model and manufacturer, otherwise a cross-connection will result, which will result in a much greater risk for the installation.

With the increasing number of new products and manufacturers entering the market, this concern should be even greater, as there is no defined connector standard for this use. It is the responsibility of the installer, who is already concerned with several other functions, to check the compatibility between these connections.

For example, in a 60 kW rooftop system using 300 Wp modules, when using a string inverter system, the approximate number of electrical connections is 200. For a system using module-level electronics, this number increases for approximately 600 connections, resulting in a more complex system, more expensive to install and more susceptible to failures and fires.

Table: Number of devices and connections in a string system versus MLPE

| String Inverter | MLPE | |

|---|---|---|

| Electronic devices installed on the roof | 0 | 200 |

| Approximate number of direct current connections | 200 | 600 |

| Estimated number of electronic components in the system | ≈ 2,000 | ≈ 60,000 |

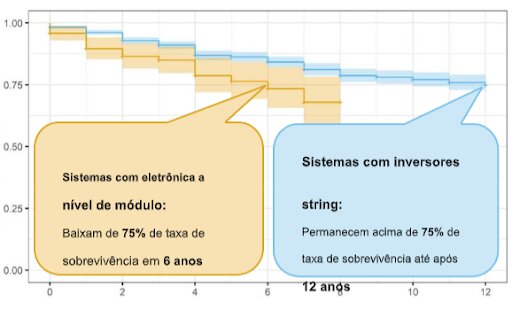

Another fact to take into account is that as photovoltaic installations become older, the greater the risk of equipment failure and the greater the risk of fire [7 and 11].

On the other hand, a lean installation with few components will suffer this effect less than an installation with module-level power electronics, such as optimizers, for example.

Lower reliability, during the system's useful life, means greater chances of the installer having to carry out site visits. In the case of installations using optimizers, in the event of failure, greater services may be placed on the roof, which could result in accidents.

Safety for firefighting professionals

In order to protect the fire department professional when fighting a possible fire, it is proposed to install power electronics at module level, with devices that promise to turn off the photovoltaic arrays so that the professional can access the roof without the risk of receiving a shock from the photovoltaic array [6, 8 and 9].

In the USA this type of system is mandatory, although the number of incidents where fire department professionals received shocks from photovoltaic systems is extremely low [10]. These electronic devices operate via communication protocols with each other. After remote activation, they reduce the array voltage to up to 80 V [12].

But in the event of a fire, even after activating the quick shutdown system, contact with any surface that may be energized [6 and 8] is not recommended, such as the photovoltaic modules themselves and the structure that makes contact with them, as that poor performance of this equipment may occur, due to damage caused by the fire itself or performance failures, since this equipment may have been exposed to rain and high temperatures for decades.

This equipment can prevent electric shock, but does not guarantee total protection for the professional during firefighting, and can create a false sense of security for the professional.

With the rapid advancement of technology resulting in an increase in the open circuit voltage Voc of the modules over the years, these devices are losing their effectiveness in interrupting the electric arc. With the increase in connections and the great possibility of causing cross-connections, this equipment can contribute to an increase in the number of fire incidents.

Security of your investment

SMA is a company that has been operating in the market for 40 years, most of these years spent developing safe equipment for photovoltaic systems, with more than 100 GW of inverters installed worldwide, and more than 25 million systems sold, equivalent to 100 nuclear power plants. Investment in research and development and security is the root with which SMA has established itself in the global market.

When purchasing a photovoltaic system, the financial security of this asset is also, after the security of the lives that occupy there, one of the priorities to be evaluated. That's why SMA provides up to 10 years of factory warranty and up to 20 years of warranty coverage through an extended warranty.

SMA has been demonstrating its commitment to the global market for 40 years by providing warranty services with the same standard of excellence throughout the world. When installing a system with SMA components, you will certainly have the longest useful life of equipment tested in state-of-the-art laboratories, covered by the SMA warranty. This provides greater security for the installer and the end customer.

Conclusion

Photovoltaic systems installed on roofs are extremely important to ensure the distributed supply of electrical energy from a renewable and reliable source in the global energy transition. Over the past few decades, photovoltaic systems have proven to be safe.

In order to guarantee the greatest safety of the systems and the occupants of the homes and businesses that will receive the systems for as long as possible, a correct design, a fail-safe installation and the selection of quality equipment are essential items.

To prevent fire risks, simpler systems have proven to be more effective. Less complexity means greater safety for occupants and professionals who will provide assistance in the event of an incident at the installation site.

SMA has been committed to safety, bringing leaner systems that reduce the chances of accidents for installers. With fewer devices to install and repair, reducing the risk of accidents such as fires and falls.

As seen in the development of this article, reducing the number of connections and cross-connections, one of the biggest fire risks, using fewer connectors is one of SMA's concerns, providing connectors that are exclusively compatible and do not require a special tool, avoiding errors assembly.

In cases of failure, safety devices, such as detection and interruption of arc flashes, will act and prevent this failure from developing into a fire, thus preserving the customer's life and investment. SMA is a pioneer in the development of arc flash detection and interruption solutions, integrated into the inverter, providing safe systems without the need for additional devices.

References

- Fire and Solar PV Systems – Investigations and Evidence – BRE National Solar Center

- Recent Facts about Photovoltaics in Germany – Fraunhofer ISE 2017

- TNO, Brandincidenten met photovoltaïsche (PV) systemen in Nederland.

- IEC TR 63225:2019 – Incompatibility of connectors for DC-application in photovoltaic systems

- Assessing Fire Risks in Photovoltaic Systems and Developing Safety Concepts for Risk Minimization – TUV Rheinland & Farunhofer ISE

- Photovoltaics and Firefighters' Operations: Best Practices in Selected Countries – IEA-PVPS-TASK 12 – NREL

- Zuverlässigkeit von Photovoltaik-Wechselrichtern – Technik und Informatik Energie- und Mobilitätsforschung PV-Labor – Berner Fachhochschule

- Solar Electric Systems – Safety for Firefighters – Australian PV Association

- O. Lavrova, J. E. Quiroz, J. Flicker and R. Gooding, “Updated evaluation of shock hazards to firefighters working in proximity of PV systems,” 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), 2017

- Fire Fighter Fatality Investigation and Prevention Program – The National Institute for Occupational Safety and Health (NIOSH)

- Jordan, DC, Silverman, TJ, Wohlgemuth, JH, Kurtz, SR, and VanSant, KT (2017) Photovoltaic failure and degradation modes. Program. Photovolt: Res. Appl., 25: 318– 326. doi: 10.1002/pip.2866.

- NFPA,NFPA 70:National Electrical Code 2017