A common question among photovoltaic system designers is about the use of an external stringbox when the inverter already has an integrated stringbox. There are several questions involved in answering this question.

In this article we will analyze the issue with a special look at the DPS (surge protection device) and an approach to the NBR 16690 standard.

The NBR 16690 standard – Electrical installations of photovoltaic arrays, project requirements – was published in October 2019. This publication was highly anticipated, as before that the area of photovoltaic projects in Brazil was an almost lawless land.

I say almost, because in the absence of a national standard, the engineering professional must seek guidance from international standards. Before delving deeper into the topic, let’s reflect on what a technical standard is.

Regardless of any legal definition, the engineer who designs a system must, in any case, always seek the best knowledge about the current state of science and technology.

The technical standard corresponds to the minimum set of requirements that derive from the current stage of knowledge on a given subject. The standard is a minimum reference for any area of engineering and not a limiting reference.

The stringbox and string inverters

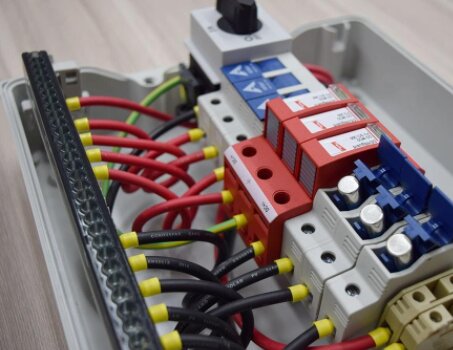

Stringox is basically made up of these four elements: set of direct current buses (positive and negative), set of fuses, disconnector switch and surge protector. You can find more sophisticated stringboxes, with string current monitoring devices, communication modules and other things, but every stringbox will always have some of the elements mentioned above.

The main function of every strinbox is to concatenate the string circuits, joining them into two buses (positive and negative) and providing a single output for connection to the inverter. We can say that the set of buses is the functional element of the stringbox, while the others are protection and sectioning elements.

Why are protection and sectioning elements necessary? The disconnector switch is necessary to allow the circuit to be sectioned under load, turning it off when necessary for any reason (in emergency situations or in any situation in which turning off the photovoltaic system becomes necessary).

The surge protector is necessary to protect the installation and equipment (mainly the inverter) against overvoltages caused by atmospheric discharges. Fuses are necessary to protect photovoltaic strings against reverse current.

According to the NBR 16690 standard, in circuits with three or more parallel strings, the use of fuses in the strings is essential. The protection components and the reasons for using them are already known to photovoltaic system designers. The central question that raises doubts is:

- Do these components need to be housed in an external stringbox or can they be integrated into the inverter?

- In other words, can the stringbox components (switch, fuses and surge protector) be built into the inverter?

In addition to the protection and sectioning functions, stringboxes naturally have the function of concatenating the various strings of the photovoltaic system and providing a single output for the inverter, as mentioned above. The doubt about the need for a stringbox has arisen with the arrival on the market of inverters with an increasing number of string inputs.

As inverters begin to take on the function of concatenating strings, offering plugs and inputs for direct connection of strings, the stringbox loses its main reason for existing.

However, if the function of concatenating strings with external buses is no longer necessary, the inverter must incorporate protection and sectioning functions, including fuses for strings, surge protector and disconnector switch.

Is it sufficient or is it advantageous to have protection functions integrated into the inverter? Does the cost reduction by eliminating the stringbox bring benefits to the safety of photovoltaic systems? Do technical standards allow you to dispense with the external stringbox? Are the standards right or wrong?

These are the questions we will try to answer below.

The NBR 16690 standard

According to Section 1 of NBR 16690: “This standard establishes the design requirements for electrical installations of photovoltaic arrays, including provisions on conductors, electrical protection devices, switching devices, grounding and equipotentialization of the photovoltaic array. The scope of this standard includes all parts of the photovoltaic array up to, but not including, energy storage devices, power conditioning units or loads. (…) The objective of this standard is to specify the safety requirements that arise from the particular characteristics of photovoltaic systems. Direct current systems, and photovoltaic arrays in particular, carry risks beyond those arising from conventional alternating current power systems, including the ability to produce and sustain electric arcs with currents that are no greater than normal operating currents.”

If you are going to design any type of photovoltaic system or solar plant, it is good to pay attention to NBR 16690. It complements other existing standards, such as NBR 5410 and NR-10, addressing subjects that are more closely related to direct current circuits. (i.e. from the photovoltaic modules to the inverter input).

Despite what we may think or think about any subject, it is good to respect the rules. Not forgetting that it must be our minimum reference and not a limiting barrier. An engineering project (like everything in life) can be much better than the minimum.

Surge Protection

Section 5.4.2 of NBR 16690 says that “To protect the DC system as a whole, surge protection devices can be mounted between active conductors and between active conductors and ground in the photovoltaic array cable and at the input of the CPU [power conversion unit, which is the inverter ]. To protect specific equipment, surge protection devices can be mounted as close to the equipment as possible. The installation of surge protection devices must be evaluated in accordance with ABNT NBR 5419 and appropriate protection measures must be implemented when the need is proven in the risk analysis. The risk analysis calculation report, in accordance with ABNT NBR 5419-2, must be part of the project documentation. IEC 61643-32 provides the methodology for protecting photovoltaic systems against overvoltages using surge protection devices. Surge protection is a complex issue and a thorough assessment must be carried out particularly in areas where lightning strikes are common.”

In short, NBR 16690 does not explicitly say that a surge protector is necessary, but its use must be evaluated according to recommendations from other standards. We know that it is necessary and is standard practice in photovoltaic projects. It is inconceivable to have a photovoltaic system that does not have a direct current surge protector somewhere, whether in the stringbox or in the inverter.

An important detail to which NBR 16690 draws attention: “The surge protection device must have self-protection at the end of its useful life that guarantees disconnection in any operating condition of the photovoltaic array. (…) Due to the characteristic behavior of the photovoltaic system, its short-circuit current varies according to solar irradiance, making the sizing of a fuse protection device in series with the surge protection device complex. Varistor-based surge protection devices, when they reach the end of their useful life, become short circuits and can ignite if not disconnected. A SPD protection fuse sized for the maximum short-circuit current of the PV array may not disconnect the surge protection device under low irradiance conditions.”

What is said above, among other things, is that surge protection devices (SPD), at the end of their useful life, conduct high currents and can ignite. There must be an interrupting device in series with the DPS.

This device may be a fuse connected in series with the DPS, whose use is rare in installations, or it may be an internal device capable of disconnecting in the presence of a high current.

In section 6.3.5, NBR 16690 also adds: “The requirements for surge protection devices specified in ABNT NBR 5410 (…) must be replaced by the requirements presented in this subsection. SPDs are incorporated into electrical installations to limit transient overvoltages of atmospheric origin (transmitted by power systems, whether alternating current, direct current or both), and surges resulting from maneuvers. Certain CPUs have some form of built-in DPS, however, external devices may also be required. In these cases, coordination between the two DPS must be checked with the equipment supplier. To protect specific equipment, SPDs must be installed as close as possible to the equipment to be protected. For protection on the DC side, SPDs must comply with EN 50539-11 or IEC 61643-31 and be explicitly rated for use on the DC side of a photovoltaic system.”

In summary, what is said above is that the DPS must be installed as close as possible to the inverter, which can be external or internal. In other words, the standard does not require the use of an external DPS and does not exclude the possibility of using an internal DPS.

The standard simply states that on the direct current side of the photovoltaic system a device prepared to operate in direct current must be used. In our mission to use the standard only as a minimum reference for projects, we will now raise some issues in which the standard's guidelines are insufficient.

External DPS: easier maintenance and greater safety

Many inverters on the market offer built-in DPS, such as the equipment shown in Figure 4. It is good that there is a DPS internal to the equipment, as the protection of the inverter's electronic circuits increases with the proximity of the DPS.

Although the NBR 16690 standard does not require it, it is recommended that there is still an external surge protector, even if the inverter already incorporates this device. This is good not only for double protection, but also for a very important reason: ease of maintenance.

DPS has a shelf life. The internal varistor of the DPS has its impedance reduced as it wears out after successive actuations. In surge protectors currently offered on the market there is a contact opening system by melting a solder point, shown in Figure 5.

At the end of its useful life, this contact is opened and the DPS completely loses its effectiveness, requiring replacement. In order to offer protection, the DPS needs to be inspected and changed periodically. An expired DPS can pose a risk to the photovoltaic system due to the lack of protection.

Access to the inverter's internal DPS requires opening the equipment by a specialized professional, while inspection of the external DPS can even be carried out by the user of the photovoltaic system. The existence of an external DPS housed in the stringbox increases the safety of the photovoltaic system, as it facilitates the maintenance of the DPS and provides a second protection barrier for the inverter.

With correct coordination between the internal and external protectors, the external DPS should absorb surges from the electrical network, saving the inverter's internal DPS. We can say that having a DPS internal to the inverter is good, but using an external DPS is even better.

Failure to maintain the internal DPS can render the device useless, putting the inverter at risk. The easy maintenance of the external DPS, illustrated in Figure 6, justifies its use. The additional cost of a stringbox with DPS is negligible compared to the cost of the inverter or the photovoltaic system as a whole.

Seeing beyond the horizons of the norm

Using the NBR 16690 standard as a minimum reference for the project, the only requirement to be observed is that the DPS must be suitable for use in direct current – and nothing more. The standard is indifferent regarding the location of the DPS: it can be internal to the inverter or it can be located in an external stringbox.

What the standard does not say is that the DPS needs maintenance and this becomes more difficult when the DPS is internal. An external DPS offers something that the standard does not provide for: ease of maintenance (in addition to double protection for the inverter, if it already has the internal DPS).

Perhaps the standard will incorporate the obligation for external DPS in the future, when the need for maintenance is perceived by users of photovoltaic systems. The internalization of the DPS in the inverter makes inspection and replacement of the DPS difficult, as illustrated in Figure 6.

An expired and unreplaced DPS becomes dangerous, as it leaves the inverter vulnerable to voltage surges from the electrical grid. Inverters, by allowing the direct connection of a large number of strings, reduce installation costs by eliminating the need for an external stringbox, but they sacrifice the safety of photovoltaic systems.

An internal DPS (incorporated into the inverter) that has reached the end of its useful life and has not been replaced is not only harmless but also dangerous. The use of the external DPS, housed in the stringbox, offers greater ease of maintenance and greater protection for the photovoltaic system.

In summary, we have several points related to the use of DPS that the photovoltaic system designer is currently unable to see in light of the NBR 16690 standard:

- A DPS without maintenance, with an expired varistor, becomes useless and exposes the photovoltaic system to risks;

- It is difficult to maintain the internal DPS, even though the presence of this device in the inverter is advantageous;

- Due to ease of maintenance, it is recommended to use an external DPS, even if the inverter already has an internal device;

- The external DPS, correctly associated with the internal DPS, offers a double barrier of protection for the inverter.

5 Responses

What is the issue with StringBox CC for microinverters? What does the standard say about it?

Excellent article Marcelo. I am entering the photovoltaic energy market, and to do so I started attending a lot of workshops, lectures and workshops. I've already taken some courses too, but there is one thing in common with all the experiences above, the lack of technical capacity of the instructors. In reality, the market is filled with system sellers with little or no technical knowledge. I recently visited the Huawei trailer and I couldn't believe it when the speaker said that the string box was unnecessary, as the inverters already had all the technology on board. Unfortunately, this is what we experience today, a lot of sales and little technical knowledge.

Hello!!

My question is: some inverters already come with DC protections already integrated into them and, therefore, some distributors sell the kits without the string box. In this case, when we assemble photovoltaic systems with these inverter models, can the assembly and installation of the string box be dispensed with? Is it up to the designer whether or not to place an SB, or necessarily, even if the inverter has integrated DC protections, should the SB be used?

Grateful!

Dear Cesar, we appreciate your comment and will forward it to the author. Regarding your question, we recommend the Canal Solar Primary Cabin Design for Solar Power Plants course. You can see information about the course at this link: https://canalsolar.com.br/curso/projeto-de-cabine-primaria-para-usinas-solares-fotovoltaicas/

Hello Villalva!

I follow your publications a lot and I have your book on photovoltaic energy. Your publications help me a lot with my projects. I discovered that you were my brother's teacher and also taught the course to my uncle, with whom I partner on photovoltaic projects. In the photovoltaic market I have difficulty finding material for consultation when it comes to higher power projects that require design and construction of a primary cabin. Could you suggest some literature that provides this type of knowledge?

Thanks!