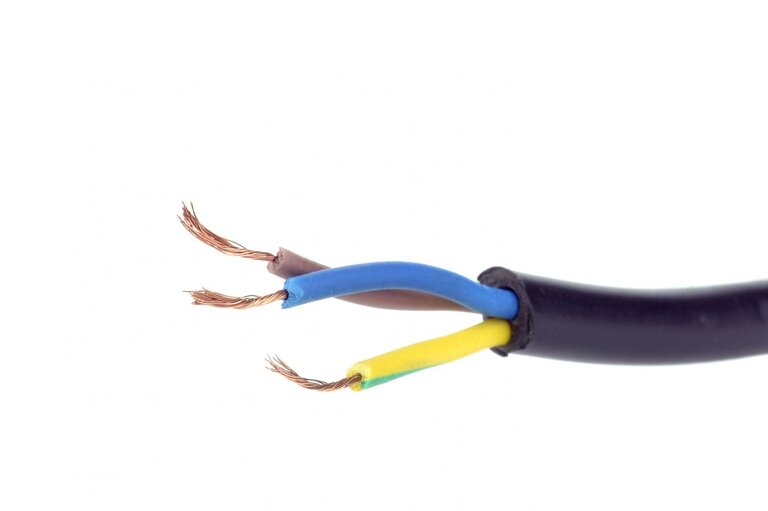

There are those who believe that electrical wires and cables are all the same, but the truth is that, among other factors, one of the most important differences that you should pay attention to when buying the product is precisely the main raw material of these conductors: copper . Copper is a chemical element from the metal family that occurs naturally on our planet, whose sources vary from small traces to rich mine deposits. Most mines operate with copper concentrations between 0.2% and 0.8%, but some of the richest ore bodies, located in central southern Africa, can contain 5% to 6% of copper. For Brazil, the major market reference for obtaining this metal is neighboring Chile. The copper ore is crushed and leached with an acid solution. From the copper-rich solution after solvent extraction, the so-called copper complex is obtained. In an electrolysis process, the metal is recovered as a cathode with 99.9% purity, a suitable index for electrical use. The problem is that this is not always the degree of purity of the copper found in electrical wires and cables in the Brazilian and Latin American markets, resulting in electrical installations that are poorly sized and, above all, unsafe for goods and people. Brazilian installation standards do not directly specify the mandatory purity of copper in electrical conductors. These standards, in the parts that deal with the types of electrical conductors in the installation, specify that the cables must comply with their respective construction/manufacturing standards. In turn, construction/manufacturing standards specify the maximum electrical resistances allowed for electrical cable conductors. The electrical resistance parameter is directly related to the degree of purity and/or the amount of copper contained in the electrical conductor. Measuring electrical resistance is much easier and more practical when compared to chemical and/or physical spectrometry tests in specific laboratories for checking the purity of copper. At the factory, if the electrical resistance test presents a result higher than the maximum established by the standard, the manufacturer will already have an indication that the copper is outside of specifications. But what happens in practice? Unfortunately, in Brazil it is common to find electrical cables on the market with conductors outside the specification of manufacturing standards, that is, with electrical resistance above the maximum permitted value. This fact occurs mostly in electrical cables with insulation voltage 750 V and thin sections (gauges) up to 10 mm2, which are widely used in electrical installations of residential, commercial and even industrial power and lighting circuits. The low quality of the cable is associated not only with the impurity of the copper, but also with the use of less copper in the construction of the conductors – the so-called “mismatched cables”. In the worst case, there may be products that combine both situations, a serious threat to people's safety, making it necessary to purchase certified products from recognized manufacturers on the market. In addition to the customer/consumer being deceived by the fact that the cable, specifically in relation to copper, does not have the quality and/or quantity actually declared, the risk of using this product in electrical installations is much more serious. Cable with a copper conductor outside the specification has greater electrical resistance, which technically means that its capacity to conduct electrical current is lower than that designed for the installation. The consequence will be the cable overheating, a fact that, in addition to increasing energy consumption, could even lead to the melting of its insulation, leading to a short circuit and thus causing a fire.

Innovation, AI and diversity to deliver the energy of the future

Innovation manifests itself in solving problems, transcending operational processes