Can we step on photovoltaic modules? What happens when modules suffer mechanical impacts?

It is common to see photos and videos of people stepping or walking on modules. Is this allowed? The answer to this question is a resounding and definitive “No”.

The answer seems obvious to some, but it is new to many. Who has never seen photos of installers leaning on or even stepping on photovoltaic modules?

Unfortunately, we come across many photovoltaic installations carried out by bad professionals, unprepared and without training in the correct handling of photovoltaic modules.

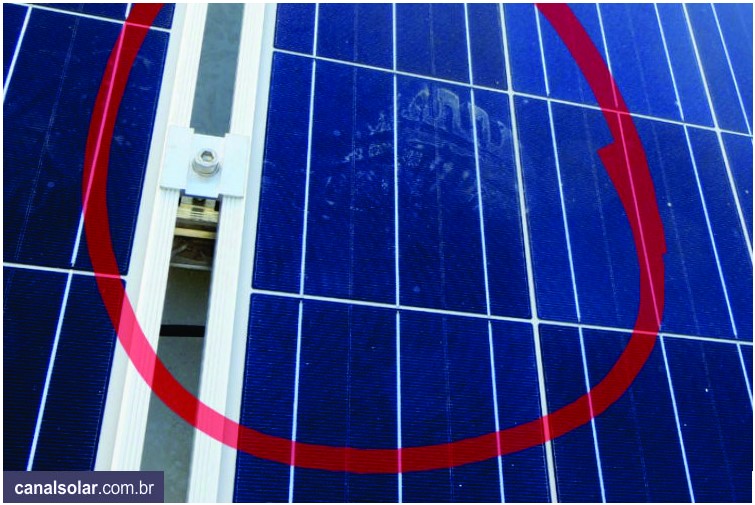

The photo below is just a small example of the terrible things that have been happening in the Brazilian photovoltaic market. The footprint in the photo was captured on a photovoltaic installation shortly after its inauguration.

The customer, and perhaps the company that sold the system, had no suspicion about the possibility of its modules having been damaged by an unprepared or malicious professional during the installation service.

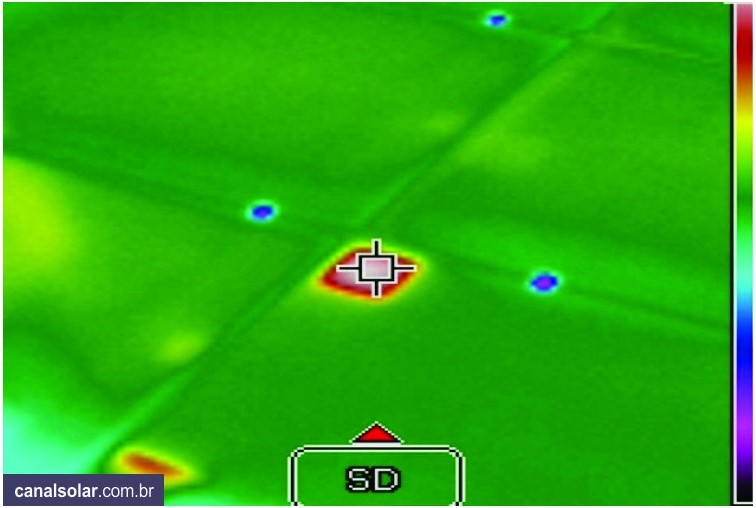

Don't believe that a simple step could ruin the module? Then see below the result of a thermography of a photovoltaic module in operation. Thermography is a photograph taken with an infrared camera, capable of identifying the temperature across the entire surface of the photovoltaic module. Hot spots and regions, with temperatures well above normal, are an indication that there is a problem in the affected part of the module.

The thermography procedure is normally carried out during the commissioning of the photovoltaic system – a set of tests and inspections carried out shortly after the construction of the solar plant, with the aim of detecting inconsistencies and defects in photovoltaic installations and equipment. In addition to appropriate tools, the professional's experience and attention are very important for detecting defects.

Thermography of the modules can reveal the existence of hotspots (hot spots) caused by defective photovoltaic cells. Defects in cells can be caused by manufacturing issues, but this is unlikely when purchasing modules from reliable suppliers, as all modules are inspected at the end of the production line, before being shipped to customers.

In most cases, when defects and hotspots are detected, the problems are caused by impacts suffered during transportation or mainly during installation. It is not uncommon to see installers stepping over modules, dropping modules, or carelessly stacking modules.

The photovoltaic module needs a lot of love. Any type of impact, even a light step, can cause microcracks in the photovoltaic cells. Microcracks are invisible and their effect can only be detected using specialized tools.

A faulty module can compromise system performance or can cause a fire in extreme cases. The defect will not be noticed if thermal analysis is not performed during system commissioning. Commissioning any photovoltaic system is very important.

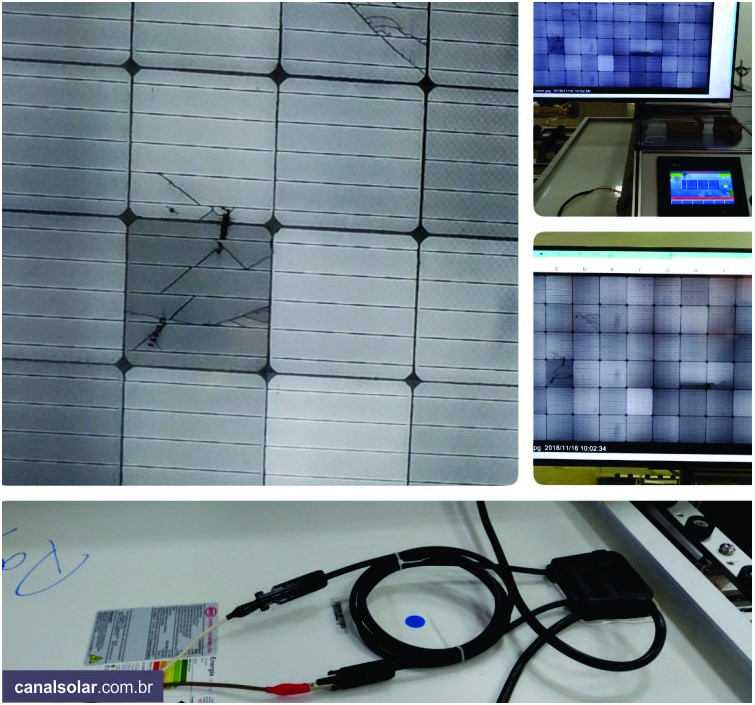

And if the module is already defective, how will I know? Firstly, it is always a good idea to use modules from trusted manufacturers and suppliers. Large manufacturers have their products certified by international standards. One of the tests that the standards require is electroluminescence. This test can only be done at the factory, as it uses special equipment that allows a kind of x-ray of the module to be carried out.

In the photographs above we see the results of an electroluminescence test, in which it is possible to verify several microcracks in some cells of the module. These microcracks are not visible to the human eye and can only be captured by a special camera.

The photovoltaic module used in the experiment above was intentionally damaged to show the result of mechanical impacts on the cells. The electroluminescence test is carried out at the factory during the assembly process. Cracked cells are replaced on the production line before the finished module is completed.

One Response

How much hail can the modules withstand?