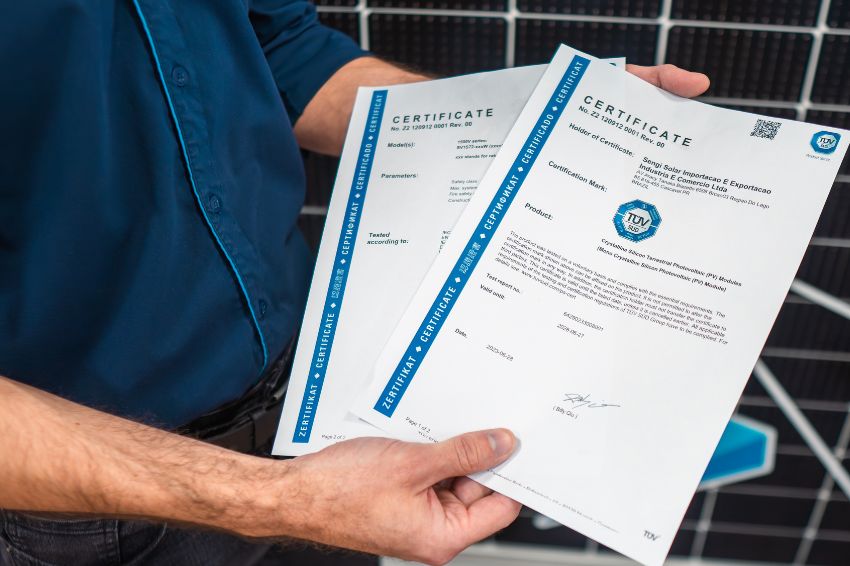

The Brazilian manufacturer of photovoltaic modules Sengi Solar, member of the Tangipar Group, got the TÜV approval seal IEC 61730 and IEC 61215. TÜV is a leading global organization in certifications and quality testing, with extensive expertise in various sectors, including solar energy.

According to the manufacturer, this approval seal guarantees that products and processes are in compliance with compliance with regulatory requirements and serve the most high international safety and quality standards.

“This achievement represents a significant milestone for Sengi, demonstrating our commitment to offering high standard photovoltaic modules”, highlighted Murilo Bonetto, Research and Development Manager at Sengi Solar.

“For Sengi customers, TÜV certification offers the peace of mind of purchasing reliable, safe and proven quality solar products. TÜV certification is recognized throughout the world, facilitating the global commercialization of Sengi products, including in strict regions, such as Europe, where TÜV certification is necessary for sales”, he added.

The company reports that its modules were subjected to rigorous TÜV tests and evaluations, seeking Validate the durability, quality and safety of your products.

For this certification, the company carried out two stages. First, it sent TÜV several modules taken directly from the Sengi production line, which were subjected to rigorous tests, such as high temperatures, freezing, physical shock, electrical tests in extreme power conditions, in addition to other evaluations.

At the end of this stage 20 quality tests and 30 safety tests were carried out, ensuring that Sengi solar panels meet the highest international requirements.

In the second stage, with the documentation and product durability analyzes carried out, TÜV analyzed all the company's documentation and inspected the production process to ensure that all factory operating rules were being complied with. At this stage, an inspection of all existing documents and all line processes was carried out.

“With TÜV IEC 61730 and IEC 61215 certification there is an international guarantee, valid worldwide, that your product meets the highest requirements. This certification is more highly regarded than local certifications, such as Inmetro, in Brazil, facilitating the entire process of legal release for the sale of Sengi products to the rest of the world”, concludes Everton Fardin, director of Operations and Engineering at Sengi Solar.

TUV Certification

Currently, TÜV carries out all safety and quality tests established by IEC (International Electrotechnical Commission), the international commission that standardizes rules for photovoltaic products.

By carrying out tests, it is possible to obtain an in-depth assessment of the module's level of security and quality. By obtaining the TÜV seal, there is substantiated proof that the product presents the performance required by the most demanding international bodies.

TÜV certifies not only the product, but also the entire production line, ensuring that the production process, environment, suppliers, everything is in accordance with the requirements, ensuring that the entire production process, from end to end, is of a high standard. .

One Response

Congratulations on the excellent report.