A growing adoption of photovoltaic systems as a source of clean and sustainable energy highlights the critical need for regular maintenance to ensure its efficiency and longevity. The effectiveness of these systems depends significantly on a proactive approach to maintenance.

A preventive maintenance plays a fundamental role in maximizing the performance of photovoltaic systems. Regular inspection of solar panels, inverters, cables and connections is crucial to identify and correct potential problems before they impact plant performance.

We can highlight the periodic cleaning of the modules, which is directly linked to energy production, and checking the integrity of cables and connections, as they guarantee not only proper functioning, but also the UFV security (photovoltaic plant).

Wear, corrosion or loose connections can result in energy losses and, in more serious cases, accidents and permanent damage to the system.

The use of suitable equipment for photovoltaic systems, workforce training and investment in technology are essential for this type of service, which will vary according to the size and particularities of each installation. Technology tends to make the O&M service increasingly productive, improving the performance of plants and guaranteeing the useful life of equipment.

Use of robots for cleaning modules and vegetation control, drones for aerial thermography and image analysis using AI, monitoring performance and performance ratio (PR) using BI software, all of this contributes to strengthening the sector, but must be analyzed and applied according to each customer’s expectations and needs.

One of the main aspects of innovation is the cleaning of modules using machines and robots, which can vary according to the type of plant (fixed ground, tracker, roof, floating).

One of the most comprehensive solutions are rotary brush and tracked movement robots, which have a productivity of 1 MW to 3 MW per day, with an investment of R$ 80 thousand to R$ 300 thousand depending on the manufacturer's brand and model.

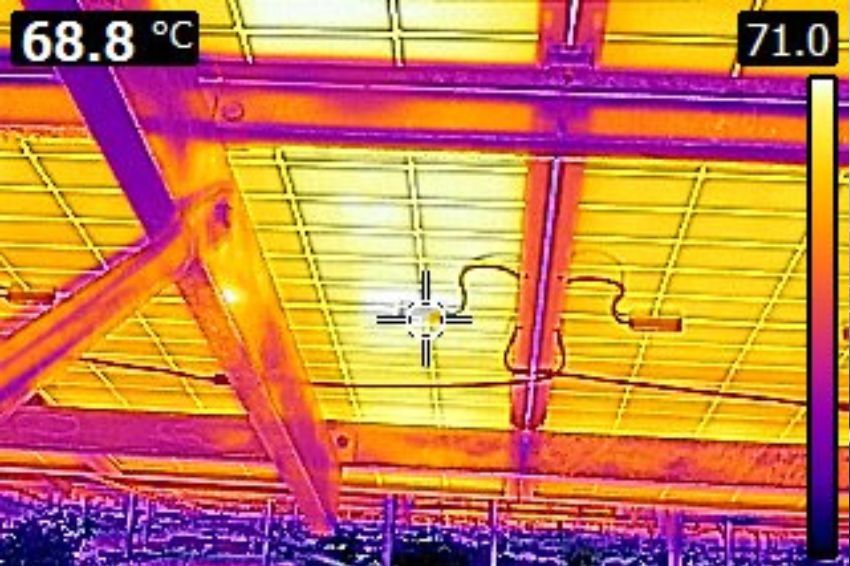

Another highlight is the use of drones with a high-resolution thermal camera for thermography of the modules, which results in a very high gain in productivity (exploring up to 2.5 km² per hour of flight) and improvements in inspection quality, as the use of AI (artificial intelligence) and software contribute to reducing human errors in analysis (the plant thermography can have thousands of photos).

Remote monitoring, performance sensors and alert systems are valuable tools that help in the early identification of problems, allowing a quick and effective response.

Remote monitoring must be carried out by a trained professional, as due to the nature of photovoltaic energy and the multitude of equipment available on the market, a complete data analysis of the system is still necessary to obtain assertive information that generates insights for predictive and corrective actions .

In this area, the use of software and “SCADA” model systems is also evolving rapidly, which shows the importance of having a capable company that is always investing in technology and training combined with technical scope.

UFV maintenance and operation services are seeing a huge increase in demand. It is important to analyze the needs and scope of each plant in order to be able to serve them efficiently.

The importance of proper maintenance is fundamental to long-term success and the continued efficiency of these facilities is directly linked to the implementation of quality equipment and services, not only extending the useful life of the system, but also ensuring maximum energy production. Ignoring or neglecting maintenance can result in significant losses in efficiency, increasing operating costs and compromising the economic and environmental sustainability of projects.

The opinions and information expressed are the sole responsibility of the author and do not necessarily represent the official position of Canal Solar.

One Response

Excellent article, I would however point out something that was not mentioned in the text, which is the STRUCTURE part. We are Integrators here in Maranhão and, unfortunately, we have seen a lot of inappropriate use in this regard.