In a packaging factory, the plastic processing machine is the item that consumes the most electricity. Before the constant rise in energy tariffs, renewable sources have become an alternative for companies in this segment to maintain production at less cost.

This is the case of Northeast Multipack, which produces an average of seven million pieces per month, including ice cream containers, PET bottles and gallons for water, soft drinks and cleaning products.

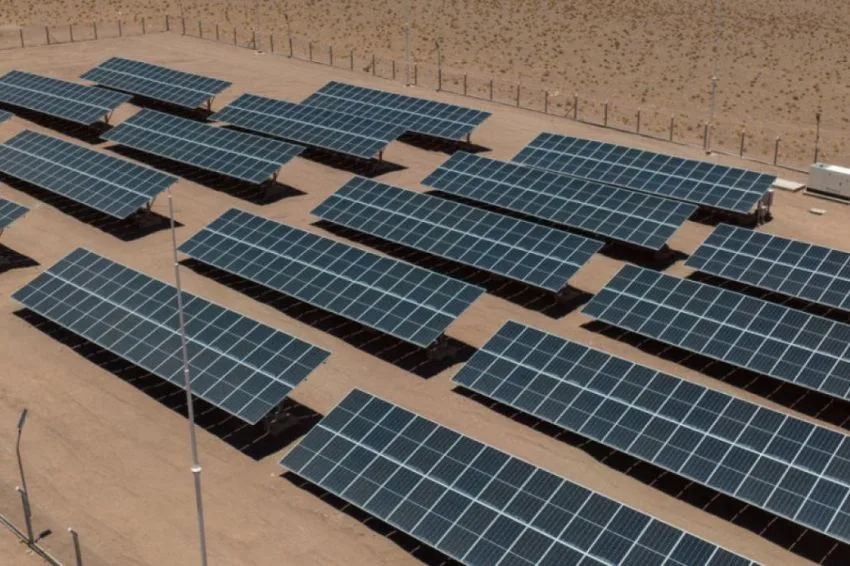

To reduce the electricity bill, the company installed a solar plant at the plant in the Macaíba industrial zone, in Rio Grande do Norte. In total, they are getting a 75% economy.

Previously, they paid around R$ 17 thousand per month, an amount that corresponds to around 5% of the factory's expenses. Just over six months after installation, the system reduced electricity costs to R$ 4 thousand per month. For now, the savings generated are used to pay for project financing.

Glauber Jacome, director of Multipack, highlights that the savings provided by photovoltaic technology were decisive for investing in an own energy generation system.

“We had been using solar for three years in another company in the group, the cleaning products factory, and last year we decided to install the photovoltaic plant in the packaging factory”, he states.

Designed by Enerbras Energias Renováveis, the plant occupies an area of 1,700 m² of the factory roof. The system, with almost 350 kWp, has around 800 440 W modules from Axitec, connected to nine Fronius Eco 27.0 inverters, capable of generating 600 thousand kWh.

According to Helder Ferreira, general director of Enerbras in Brazil, the Fronius Eco model was the most suitable for the project, due to its reliability and low maintenance cost.

“In addition to having a monitoring system with extended memory, which protects historical data in the event of loss of communication with the Internet, it also offers the possibility of installing a Smartmeter (intelligent energy meter). The reliability of the brand and the direct technical support in Brazil that it offers were also decisive for the choice”, concludes the executive.