A Vigorito Chevrolet – Chevrolet brand vehicle dealership chain store – located in Santo André (SP), is in the cpath to zero CO2 emissions with the installation of a solar plant.

According to the Sunergy, the company responsible for the design and installation, the project obtained a savings of almost R$ 60 thousand annually with the construction of a 145.25 kWp system.

O Estimated payback (return on investment) is 6.9 years. The works began in July 2020 and were completed in October of the same year.

In total, 415 photovoltaic modules were used, from German manufacturer AE Solar, and three inverters (Sunny Tripower), limiting the maximum injected power to 115 kW, also German SMA.

“When we studied and carried out an impartial analysis of the options that the market offers, and the capacity of the company that will assemble the system, we quickly realized the difference in technology and reliability of the equipment and the installer”, emphasized Hermes Shincariol Junior, managing partner of the Vigorito Group.

In the executive's view, with this pair of technological solutions – from SMA and AE Solar, and the capacity demonstrated in the exchange of information between the Chevrolet dealership and Sunergia – they chose to close the contract and begin to obtain savings with solar energy.

“Now, after around three years of the system being installed, we can confirm that the plant is in fact aligned with all the details presented at the time of closure. With the reduction in expenses, we will expand our energy production to the group’s other stores”, he highlighted.

“Thinking specifically, the photovoltaic solar source is an excellent way to guarantee energy availability, modernize the electrical sector and decentralize the energy production economy”, added Junior.

Ramon Nuche, LATAM director at AE Solar, also commented on the partnership and highlighted that the company's commitment is to bring technological solutions and innovation that will actually bring savings to customers. “That’s why we are expanding our portfolio every day with tailor-made solutions for each project.”

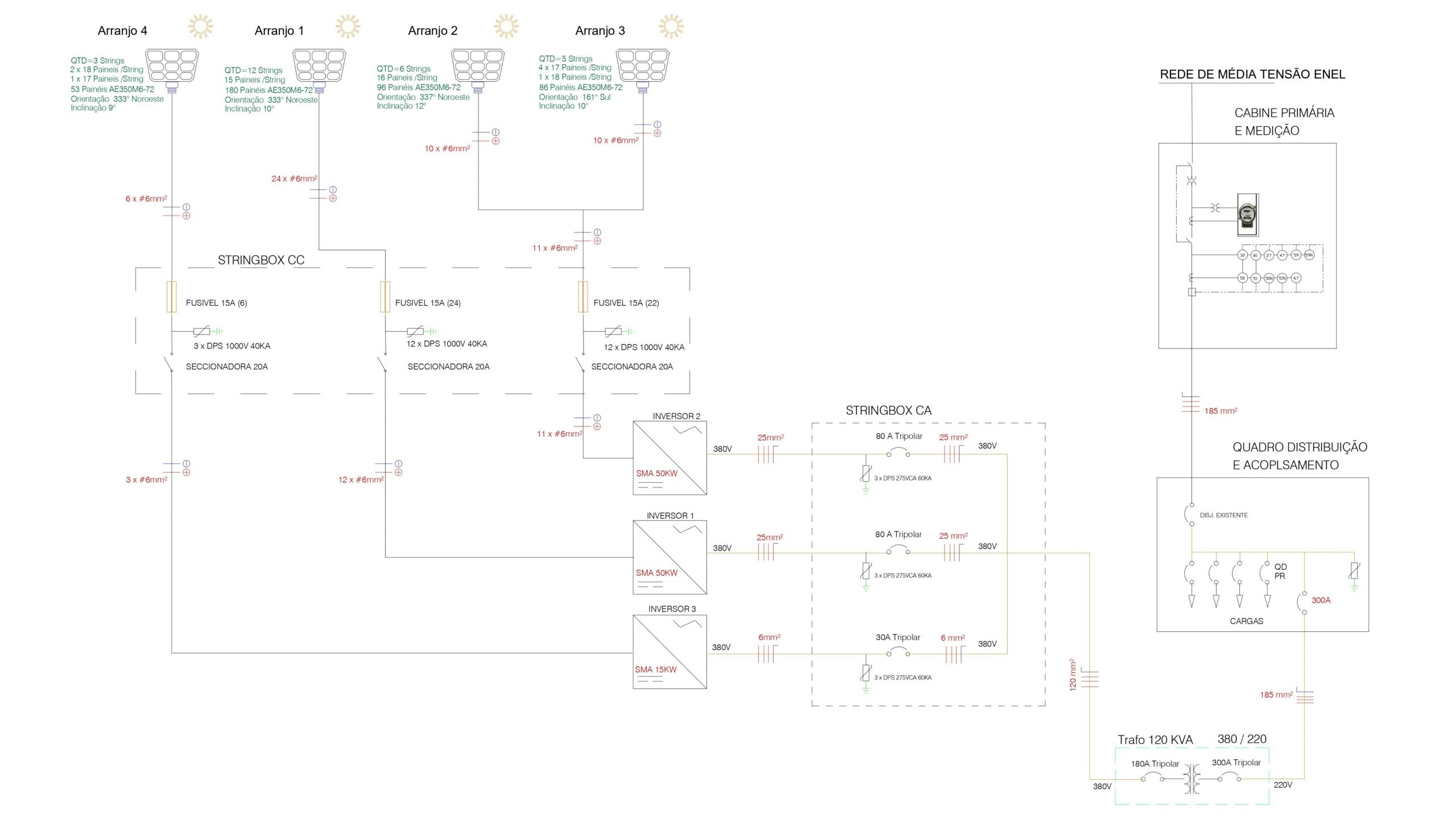

General project characteristics: PV modules

According to Sunergia, the panels were fixed using anodized aluminum metal structures with high corrosion resistance. “The plates were mounted directly on the roofs using self-tapping screws that are fixed to the structure that supports it, providing high resistance to winds.”

The intermediate and final electrical connections between the modules were made using a quick-connect type MC4 connector. Each photovoltaic array, in total 26, was connected to an input of the protection and switching panels (stringbox) and were distributed to the 26 available inputs of the three inverters.

Strinbox

Sunergia stated that on the DC side the protection is performed by a 1000 VDC / 60 kA SPD (Surge Protection Device). This circuit is protected by two 16 A cartridge-type fuses (one on each pole) with a protection curve and interruption level suitable for application in photovoltaic generation.

“A 20 A / 1000 Vdc bipolar disconnector switch allows the inverter input to be disconnected for maintenance work”, explained the company.

The AC side consists of a protection panel with 80 A circuit breakers for each of the two 50 kW inverters and a 25 A circuit breaker for the 15 kW inverter. For protection against surges, they used a SPD /275 Vac / 60 kA Class II, for each phase.

“On the AC side, a 120 kW 380 / 220 V isolating transformer was also installed, in star connection with neutral (YNYN0), to adapt the voltage levels of the photovoltaic generator and the electrical installations of the building by means of a protection device 300 circuit breaker on the connection board”, they pointed out.

Grounding and cabling

The building has grounding grids in the TT scheme, resulting in a grounding resistance of less than 15Ω, even on dry soil. “The original installation consisting of two 2.44 m rods with a section of '5/8' buried in the ground below the house guarantees the quality of the grounding”.

Regarding cabling, all cables (DC side) were installed in exposed cable trays appropriate for their application (apparent on the wall).

“In addition to this protection, all DC power and grounding cables used in the installation of the modules are suitable for external installation, subject to sunlight and bad weather”, they commented.

“An external channel conducts the power and grounding cables between the PV inverter installed on an external wall and the QGBT (General Low Voltage Switchgear), guiding the AC circuits to the PCC (Common Connection Point with the grid)” , the company concluded.