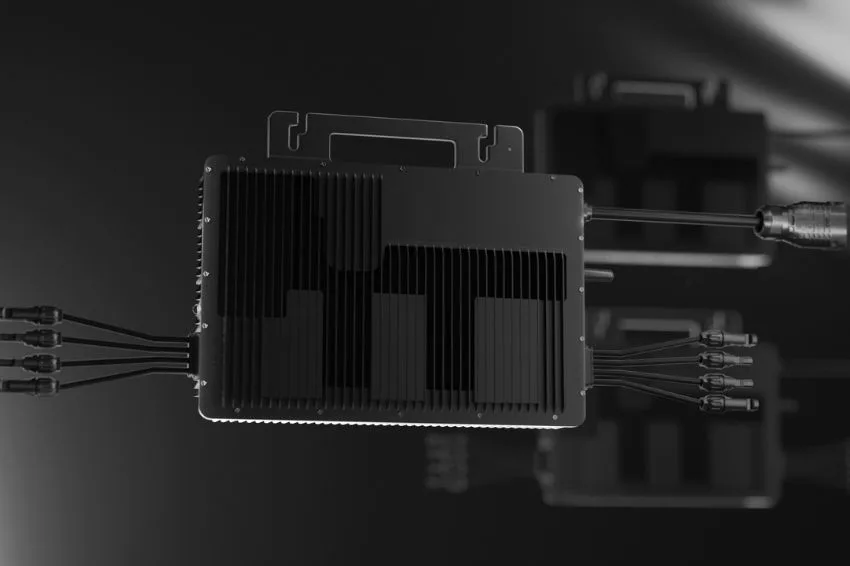

ARaymond nationalized the production of a fastener on Brazilian soil in July this year, an item that until then was produced only in China, to serve the entire global market.

The solution called PowAR Snap S+, developed for roof installation, can also be used in ground structures and carports, promotes speed in installations, simplified logistics, reduction of labor and the replacement of the use of nuts and bolts.

“With the high demand on the world market, we saw great potential in nationalizing the item, removing the production bottleneck at the Asian plant. This process brought a very quick result, since the demand to serve all of Europe is very high, in addition to the accelerated growth of the Brazilian market”, comments Andrezza Prado, Key Account Manager Jr at ARaymond.

“Our manufacturing process needed some adaptations to absorb this new demand, in order to meet our customers' lead-time, such as: hiring overtime, improving the intermediate stock layout, adapting the machine, renegotiating the strategic acquisition of materials. prima and partnership work with our service suppliers, such as heat treatment, where a change in the process was also necessary in order to meet this high demand”, highlights Rafael Avila, Key Account Manager at the manufacturer.

ARaymond introduces new clips for fixed ground structures and trackers

The company, which had already announced a new line in second half of this year, aims to optimize time and cost for the integrator, helping with simple assembly of the project.

Since the clips are attached to the bottom of the module frame, the need for the installer to climb on them during installation is eliminated and consequently preserving the equipment from potential damage, also eliminating the need for ladders or scaffolding.

Andrezza also highlights the great challenges of localizing a product like this due to the trade barriers, machinery development and all the engineering work involved throughout the process, until the final production of approved parts in accordance with the requirements.

The company also reported that due to the great demand for other fixing for trackers, is working on the nationalization of other items, which will bring greater agility in production and local and global service, in addition to the development of a quick grounding solution to meet Brazilian standards.