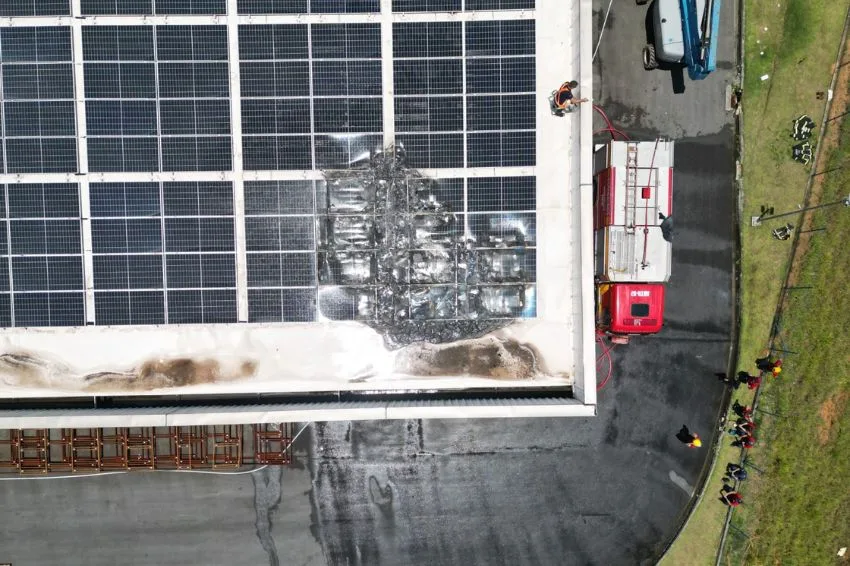

One solar power system caught fire in a industrial building which is located on the banks of BR-101, in Araquari (SC), this Tuesday morning (16). The extent of the roof affected by the flames was approximately 30 m².

According to the Fire Department, It took 15,000 liters of water to put out the fire, with the help of a truck and three lines of hoses, set up to begin fighting the flames remotely.

After containing the fire, the corporation awaited the arrival of a company platform to be able to access the area where the photovoltaic panels were installed and carry out the aftermath, avoiding further reignitions.

Fires in facilities

Although the cause of the fire is still being determined by local authorities, it is important that some care ever be taken by installation companies to avoid accidents in any photovoltaic installations.

Thiago Farias, engineer at Solar Channel, explains that great part of the problems in electrical circuits are related to the undersizing of Electric cables and failures in connections, needing to be well executed.

“The problem of sizing of electrical cables generally occurs due to negligence in the application of technical standards, which in the case of photovoltaic systems are mainly: those regarding the sizing of low voltage cables (NBR 5410), the installation requirements of photovoltaic arrays (NBR 16690) and those that specify cables for application in photovoltaic systems (NBR 16612)”, he points out.

Regarding the connectors, the professional highlights that the most common error is in the crimping process, especially with the use of improvised tools, especially hammers and pliers that are not recommended by the manufacturer.

“The correct thing to do is to use specific tools for each type of connector, since the electrical connection between the cable and the connector depends on the use of specific equipment. Some manufacturers even indicate which tools should be used in their installation manual”, he emphasized.

The engineer emphasizes that periodic maintenance must be carried out with due checking and retightening of the connections of the installed systems.

2 Responses

Good morning!

It's not just connector problems. We have already inspected installations with sizing problems, with overload on the MPPTs of the inverters, DC cables in the same rail with AC cables. This is very common. The concessionaires do not observe this fact, and what they approve is the Installation Registration, the compatibility of the protection circuit breaker and the installed power. The CREAs, in turn, do not monitor anything. So what we see is complete absurdity in the facilities.

Good afternoon,

I would like to know if preventive maintenance (thermovision) was carried out on the panels periodically.

Do you recommend this action and could you suggest a report on the importance of this type of maintenance up to the main distribution board.

It is a company specialized in this type of service and professionals.