"A TOPCon technology is the development trend of the photovoltaic industry in the future, which can not only improve the efficiency of photoelectric conversion, but also more quickly develop the mass production process by improving the cost-benefit ratio of modules.” This is what Marcel Coelho, Product Manager at Osda Solar.

“PERC cells have a theoretical efficiency limit of around 25%, which use 'passive contact' in their most advanced technology. However, there are some manufacturers that produce N-type bifacial TOPCon cells whose efficiency reached 25.2% to 26%, which could be higher, depending on developments”, he highlighted.

“In the long term, the revenue premium from TOPCon solar panels is much greater than the cost increment. And as the technology matures, there is still room for cost reduction”, added Coelho.

How to popularize TOPCon technology?

According to him, currently, the production capacity of Osda TOPCon modules is growing worldwide. “In 2022, a trend of significant growth in production began.”

“Production of this technology is expected to reach 16.7 GW for the full year, an increase of around 500% compared to 3.3 GW in 2021. It is further estimated that TOPCon's accumulated production capacity will exceed 80 GW until the end of 2023,” he said.

For the expert, 2022 is becoming the first year for the large-scale commercial application of TOPCon technology.

Comparison between TOPCon and conventional modules

In his view, the theoretical efficiency of TOPCon is much higher than that of type P. “The current production at maximum efficiency does not exceed 24.5% to 25%, a fact that is overcome with TOPCon technology which has the advantages of low attenuation, high bifacial ratio and low temperature coefficient.”

“For customers with ground or rooftop installations, if we compare TOPCon modules to PERC modules, the size of the panels versus the power of the TOPCon modules has not increased at the same rate. It not only saves on installation costs and site space, but also significantly improves photovoltaic yield,” he highlighted.

Furthermore, it pointed out that in the same version, TOPCon panels provide a power increase of 5% to 6% compared to PERC, with first-year attenuation of the temperature coefficient and improved low-light performance, as well as generation of full life cycle energy than PERC.

“This means that TOPCon modules will have an increase in production compared to PERC from the same perspective of energy generation cost analysis,” he stated.

Savings on shipping costs

Compared to PERC, the Osda Solar Product Manager commented that the number of TOPCon panels increased in the same space as an import container, due to their physical construction.

“For a 40 HQ container, PERC can only contain 620 pieces, while TOPCon, 570 W or 575 W, can reach 740 pieces, which will greatly save shipping costs, better diluting freight in the final composition of the product. price of the product.”, he exemplified.

Economic benefits

“In general, the profitability gain from TOPCon components is much greater than the cost increase. It is not difficult to see that the advantage of the economic benefits has been obvious and rewarding”, he pointed out.

Therefore, Coelho emphasized that leading manufacturers are actively seeking technological advances. “And one of the most important directions is the technological route of increasingly efficient modules using TOPCon”.

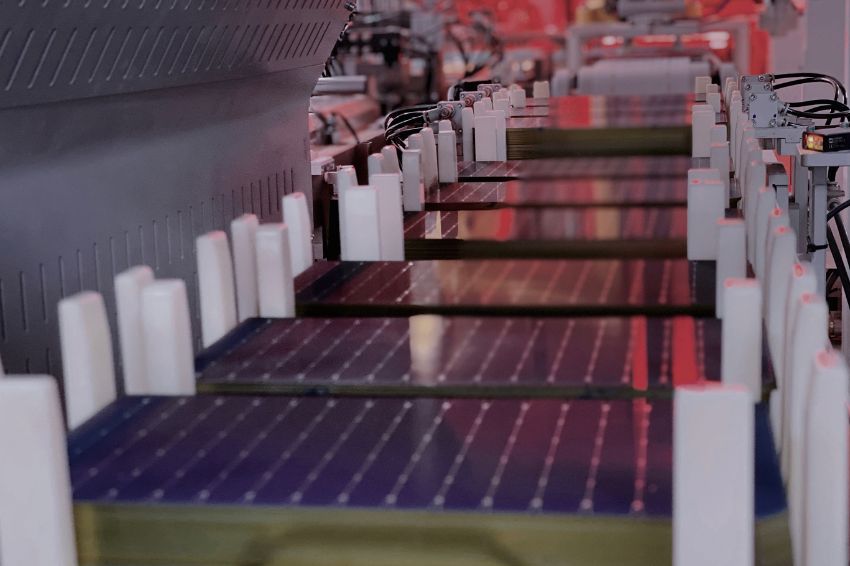

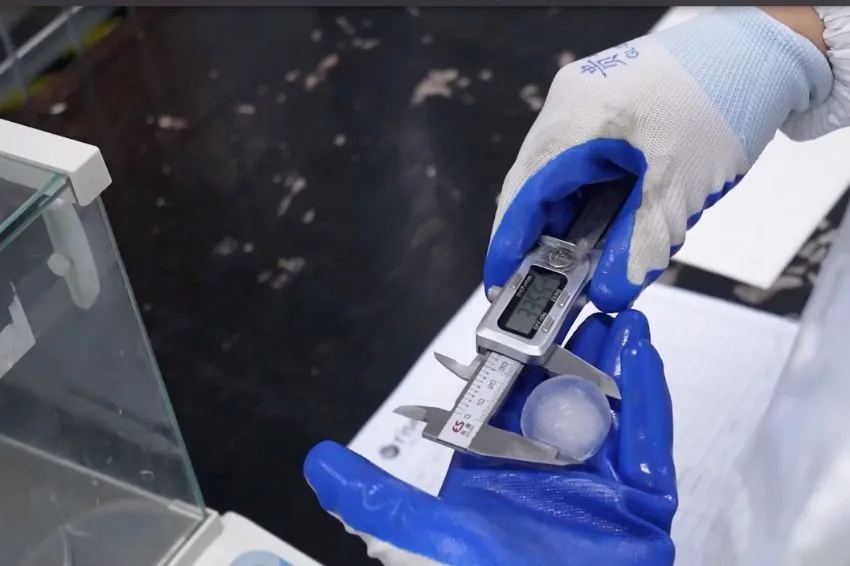

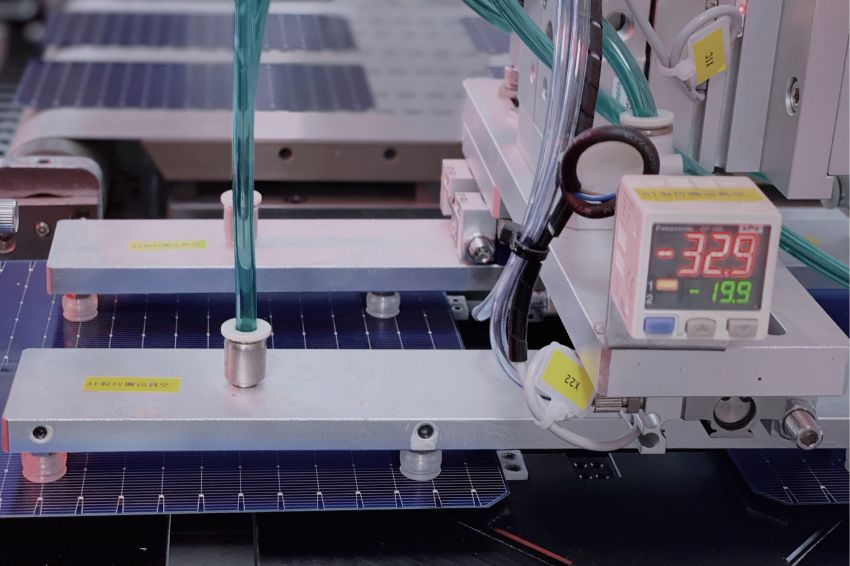

New Osda factory

Osda Solar announced that it built this year, in Linyi, Shandong province, China, a new factory to produce 10 GW/year with TOPCon cell technology, serving high-efficiency modules in the solar energy market.

The enterprise has five production lines, with emphasis on 570 W and 575 W monocrystalline panels, which have CE and Inmetro (National Institute of Metrology, Quality and Technology) certification for Brazil.

Furthermore, they highlighted that the factory has an R&D (Research and Development) center focused on energy storage systems.

Operation in Brazil

In June this year, the company had already opened a office in Brazil, in the city of São Paulo, with the aim of serving customers more efficiently and investing in the expansion of the national market.

The manufacturer also has offices for this model in other countries such as the United States, Netherlands, Germany, Denmark, Poland, Bangladesh, Thailand, India and Yemen. Furthermore, it is planned to install a warehouse by the beginning of 2023. The location aims to provide products for immediate delivery to meet the most urgent demands.