A Risen Energy announced that it has compiled the experiences and knowledge accumulated in relation to the development and industrial application of wafers in ultrathin silicon on a white paper. This is the second technical report released by the company, which last year released one on modules with HJT technology (heterojunction).

According to the manufacturer, as is widely known, silicon wafers, metallization pastes and equipment costs account for more than 90% of the total values of HJT cells.

“The silicon wafers alone represent 55%. Therefore, it is evident that reducing the costs of such wafers is one of the main means to boost heterojunction mass production”, they highlighted.

Risen has made significant progress in the technical development and industrial application of ultra-thin silicon wafers after years of R&D (Research and Development), which has led to cost reduction and boosted the competitiveness seen today in this technology.

Currently, the company said it has mastered the mass production of cells using 110 μm and 100 μm ultra-thin silicon wafers, with the ability to produce wafers with thicknesses less than 100 μm.

Technological advancements

The photovoltaic industry, as a sector driven by technology, has gone through several rounds of technological interactions whose objectives have always been related to improving efficiency and optimizing the production chain in search of greater sustainability and cost reduction.

Technically, as the efficiency of P-Type cells approaches its peak, N-Type cells have become the new trend of the day, given the potential to achieve greater efficiencies, including approaching theoretical efficiency limits for cells single junction silicon.

According to Risen, heterojunction technology, as one of the main routes for N-Type solar cells, has attracted everyone's attention for its advantages and its potential to improve other characteristics, which go beyond just efficiency.

“We anticipated this change and began R&D of HJT technology in 2019. Over the years, we have invested substantial resources in the research and mass production of HJT modules, having secured two consecutive years of global leadership in HJT shipments,” they reported.

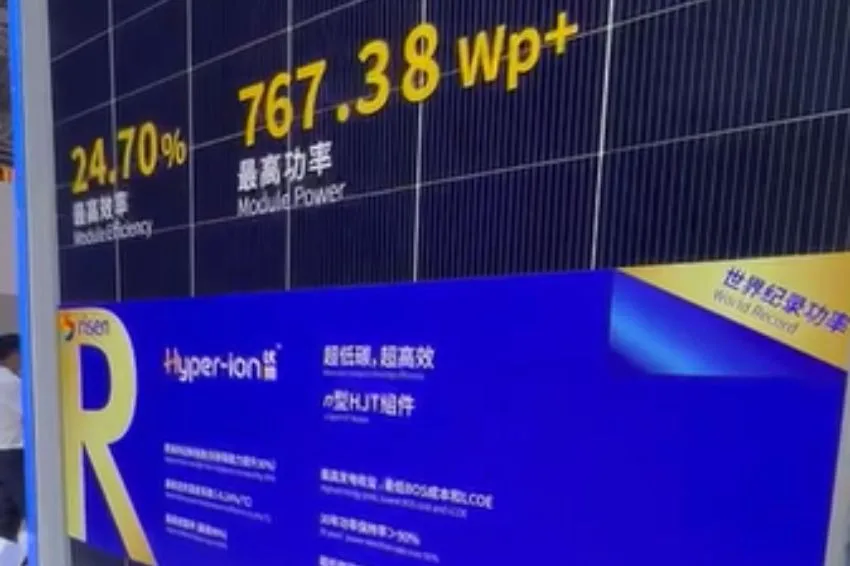

As a result of a lot of investment in the development and improvement of technology, the company's HJT panels broke, for four consecutive times, world records for HJT module efficiency, such as the Hyper-Ion line panel which had a power of 741 W and efficiency of 23,89% certified by TUV in 2023.

Risen's HJT models, according to the company, concentrate high power density, the lowest Pmax temperature coefficients and annual linear degradation, in addition to a lot of cutting-edge technology on board.

Over the years of development, Risen Energy has also carried out in-depth research into several important factors that go into achieving high reliability and cost reduction for large-scale mass production of HJT technology, making it viable and competitive.

At the end of 2022, for example, they developed and began to produce, on a large scale, ultra-thin silicon wafers and cells with zero busbar technology in the cell, known as 0BB, the use of metallization paste with a low silver content and interconnection technology of cells under low temperature, called Hyperlink, ensuring high reliability of HJT Risen cells. These technologies integrate the manufacturer's HJT modules through the Hyper-ion line of ultra-high powers 700 Wp+.

All content on Canal Solar is protected by copyright law, and partial or total reproduction of this site in any medium is expressly prohibited. If you are interested in collaborating or reusing part of our material, we ask that you contact us via email: [email protected].