It is not uncommon for reports of accidents that occur due to energized structures, as a result of a grounding and equipotentialization system non-existent or inefficient.

For a photovoltaic system to operate correctly and safely, It is It is essential that the grounding project is prepared with special attention, as it is through it that we guarantee the safety of equipment and people.

Learn more about grounding

https://canalsolar.com.br/sistema-de-aterramento-de-uma-usina-solar-fotovoltaica/

Equipotentialization and continuity

Unlike grounding, where the conductive elements must have contact with the earth, we can define the equipotentialization as the interconnection of non-energized metallic structures that make up the photovoltaic system to a grounded point.

Equipotentialization and grounding allow the electrical potential of all structures to be equal, preventing people from being exposed to risks during an electrical discharge or any other situation (such as insulation failure in cables and components).

For equipotentialization to exist, a functional grounding system is required. In solar plants, equipotentialization requires that components that have metallic parts are electrically connected and present electrical continuity.

For example, it is necessary to guarantee electrical conductivity between photovoltaic module frames and fixing structures, between inverter housings, electrical panels and other components. When we think about large solar energy systems, equipotentialization of all structures can be an expensive and time-consuming job.

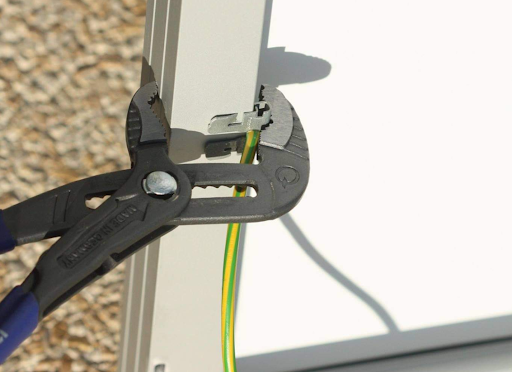

To enable equipotentialization in large plants, quick solutions are needed, which facilitate the installation task, requiring only the use of appropriate tools to carry out the service.

Rayvolt Solution

In grounding and equipotential cables or “grounding pigtails” (as they are popularly known), cable crimping is required so that it is connected with screws and nuts to the aluminum frames of the modules and subsequently to the system's grounding conductor.

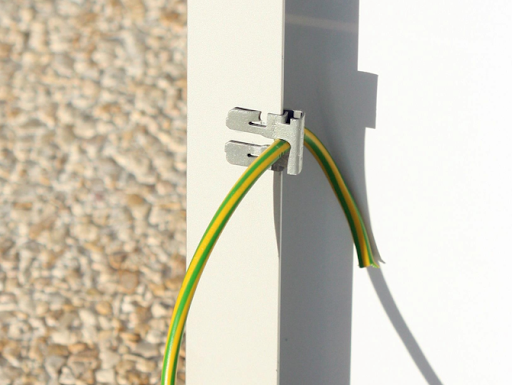

With the Rayvolt solution, crimping is not necessary, nor the connection by screws and nuts, thus reducing the risk of poor connection, which can lead to a failed equipotentialization system. As Rayvolt ground clip A single action is enough for the cable insulation to be cut and connected to the structure where you want to ground, as illustrated in the images below.

This new way of grounding and equipotentialization of structures, in addition to reducing the equipment needed to carry it out, also reduces labor for installation, consequently reducing assembly time, which provides a considerable advantage in the construction of solar plants.

A Rayvolt solution works for all modules with 1.5 to 2.5 mm aluminum frame and cross section of 6mm2 multifiber flexible cable (H07V-K6mm2).

O Rayvolt clamp is also suitable for connecting galvanized steel support rails, in addition to complying with standards IEC 61730-2:2007, IEC 60947-1:2007 and EN 60068-2-11:1999. The clip also has a grounding symbol stamped on its top face, ensuring clearly identified grounding.

It has an aluminum-rich surface treatment, thus preventing galvanic oxidation between different types of materials, and can be used in corrosive environments classified between C4 and C5 for 25 to 30 years. O clip also has a grounding symbol stamped on its upper face ensuring clearly identified grounding.

4 Responses

Where do we buy these Reyvolt clamps?

Hello, Reynaldo! Visit the ARaymond website: https://www.araymond-energies.com/en

Where to buy this quick grounding?

Hello, Lizandro! Visit the ARaymond website: https://www.araymond-energies.com/en