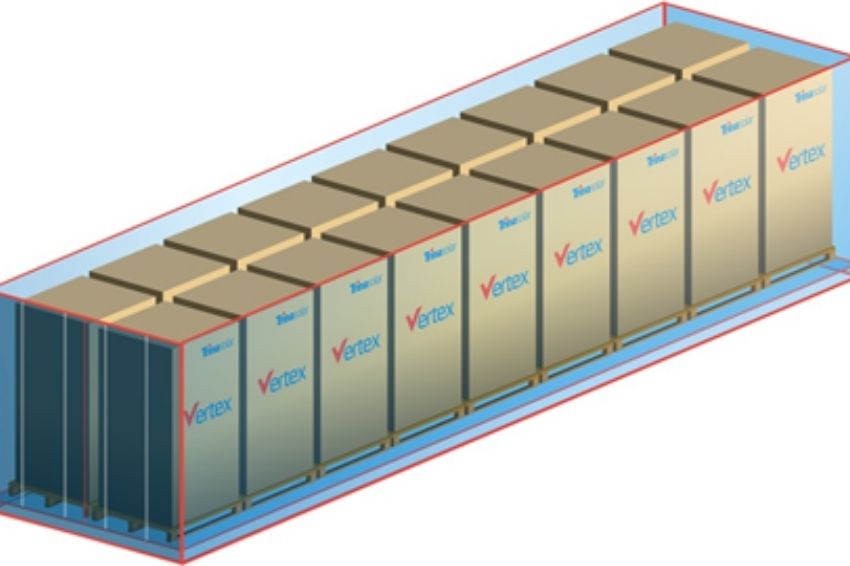

A Trina Solar introduced its global integrated 600 W+ Vertex panel delivery solution, paving the way for ultra-high power module application.

According to the manufacturer, this equipment significantly increases the power/m³ ratio in a container, reducing sea freight costs by up to US$ 1,105 per container and US$ 3,000 per project MW.

“Overseas shipments are generally transported in containers. With this in mind, we developed an innovative vertical packaging product, surpassing the module width limit of 1,135 m,” said Zhang Yingbin, head of product strategy and marketing at Trina.

Compared to conventional horizontal packaging, the company stated that the solution can increase loading capacity by 10% and space utilization by 5%, maximizing container usage.

“At a time of rising shipping costs, this solution saves 0.3 cents per watt in shipping costs from China to Europe. Assuming a container can carry 558 modules and each board is 660 W, then one container saves about U$ 1,105, cutting the cost by US$ 3 thousand per MW – calculated at the current going price of U$ 10 thousand per container,” he explained.

Performance in extreme conditions

According to Yingbin, the vertical packaging method also passed the international 3E packaging test of the International Safe Transport Association (ISTA) – an international authority dedicated to the development, design and efficiency of global transport packaging.

When a packaging design is tested, it ensures that products will be effectively protected during transportation and will not be exposed to predictable harmful elements.

China General Certifications, a third-party agency, also conducted specialized wind tunnel testing. The results verified that vertical positioning ended up being as safe and reliable as horizontal packaging in terms of unloading, storage and unpacking at the project site under extreme conditions. And it also passed the empirical test, reported Trina.

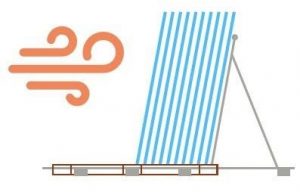

Furthermore, in one of the two wind tunnel tests that China General Certifications conducted, a hostile storage environment was simulated at the project site. The vertical package was placed on a flat surface at a 5° angle to the ground and tested for stability in a wind tunnel. The result showed that it withstood a grade 12 hurricane on the Beaufort scale.

According to Trina, the other wind tunnel test proved reliability during unpacking operations in extreme conditions. “Standing, the support is positioned on the windward side and 10 modules are placed separately horizontally and vertically on it.”

“During the test, the wind was blowing against the backs of the models and next to the stand support and, even with the panels being placed anyway, they passed the wind force 6 test”, they highlighted.

Read more: Trina Solar presents Vertex at Intersolar South America 2021

More data

The 600 W+ Vertex integrated delivery solution also took into account other processes, including logistics, storage and shipping. The company emphasized that the product upgrades standard operating procedures and unpacking tools, convenient and recyclable, which can be assembled in two minutes.

Vertex 660 W have lower BOS and LCOE for projects in Brazil

Enertis Applus+, a global solar project services provider, has completed the CAPEX and LCOE (Levelized Cost of Energy) assessment of Trina Solar's new generation of ultra-high power modules 210 (G12) and 166 (M6), 182 (M10) from other manufacturers.

Study results show that in CAPEX and LCOE, 210mm modules installed with TrinaTracker's 2P tracker outperform 182mm panels, which in turn outperform 166mm modules.

It was also found that compared to the 166-450W panel, the 210mm PV panels reduce CAPEX and LCOE by more than 3%, of which 210-660W has the best performance with the largest reduction of 4.56% in CAPEX and 4,75% in LCOE.